Cavitas’ Thermal Oil Recovery Technology

How to Revolutionise Thermal Applications in an Environmentally Friendly Way

Cavitas has over 60 years combined experience in the energy industry with a strong track record of bringing innovative downhole technologies to market. The company has developed an innovative Downhole Heater called THOR, to revolutionise Thermal Applications in an environmentally friendly way.

Cavitas’ Thermal Oil Recovery technology THOR is a reliable, cost effective and low carbon, mechanically powered heater providing 100% targeted heat downhole: 3X oil production, flow assurance, unlock shut-in gas wells.

THOR provides:

- In-situ Near wellbore Heating

- Up to 500% production increase in Heavy Oil

- Flow assurance in wax and asphaltene

- Increase pump efficiency and run life over 50%

- Restoring Production in liquid loaded gas wells

- Unblocking pipelines and risers

Cavitas’ environmentally friendly heater procedures emits only 1.51 gC02/MJ which is around 20 times less than traditional Thermal operations such as Steam Floods in Kern, California at 29.33 g/MJ. THOR’s high (90%) efficiency and targeted downhole also keep fuel costs low.

Over 40% of global remaining oil is Heavy Oil which is most effectively developed by Thermal operations. THOR’s low carbon barrels could have a vast impact on the global goal of keeping Climate Change below 2 degrees Celsius.

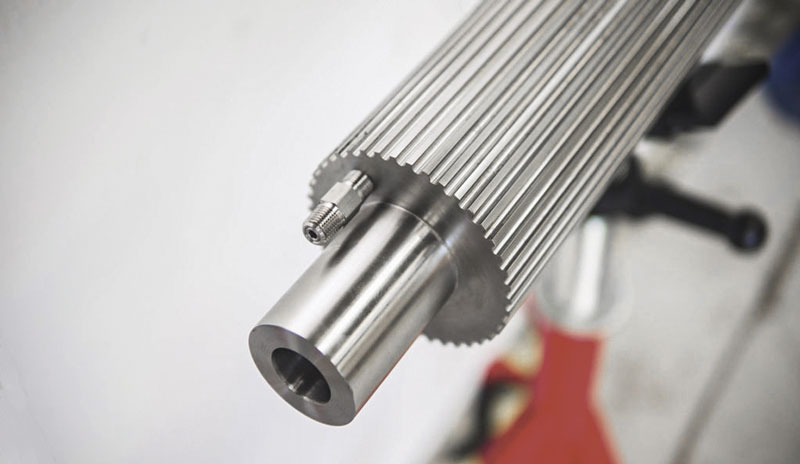

Reliable mechanical downhole heating

THOR’s mechanical design offers the highest downhole heat energy density on the market, up to 55 kW/m, 50-100x greater than typical electrical cable heaters allowing for a significantly shorter and lighter tool which is easier to deploy and retrieve.

THOR’s ingenious mechanical design avoids the reliability issues that plague Electric Cable Heaters e.g., hot spots at splices. THOR’s fully sealed design avoids free gas and solids shock loading, a key failure mechanism of pumps.

The downhole tooling requires no maintenance on its 3-5 year run life and can be monitored remotely, traditional methods require Maintenance Technicians on site 24/7.

The small topside footprint of a VSD, Transformer and Junction Box make it ideal for offshore or remote wells.

This flexible rental model can allow operators to receive a return on investment in 50 days or less.

Cavitas’ active design team and innovative spirit means THOR can be fully customised to suit all requirements that the operator has. Fully unlocking the potential of their wells in an environmentally friendly way.

What is THOR?

THOR is a simple, cost effective and low carbon, mechanically powered downhole heater to improve production in viscous oils and provide flow assurance in waxy oils. THOR also restores production in liquid loaded gas wells.

THOR is an innovative liquid filled heating element that requires only a rotational force to be applied to function. Its outer body is heated via thermal conduction and is designed to heat any external fluid passing over THOR. THOR’s Variable Speed Drive (VSD) allows total control of the downhole temperature.

THOR is suitable for deployment in injection and production wells, using thermodynamics to enhance production while limiting the build-up of waxes and scales. THOR is fully sealed, heating any fluid that flows past without any shearing or disturbance of the fluid itself. THOR is powered by a downhole Permanent Magnet Motor (PMM) since the tool is fully sealed the PMM will not be rotating as the tool is run in hole, an issue that can be associated to pumps.

How does it work?

THOR acts as a high-powered downhole heating element, heating any fluid that flows past it to a controlled target temperature, only a rotational force to be applied to function. THOR is fully sealed, nothing enters or exits the tool, meaning the production fluid is never sheared or damaged in any way.

THOR is powered by a downhole motor called a permanent magnet motor (PMM) the speed is controlled by a variable speed drive (VSD) this allows total control of the downhole temperature in real time. The higher the rotational speed the greater heat energy output by THOR, if the operator wants to increase the downhole temperature, then we increase the motor speed to match.

Why use THOR?

When heating a viscous production well THOR can more than double oil production with increases up to 700% possible at high oil viscosities. THOR will also reduce the water cut, reducing the oil viscosity improves the mobility ratio meaning more oil and less water is produced.

THOR is the highest energy density downhole heater on the market at up to 55 kW/m, this is 100 times the energy density of downhole electrical cable heaters. This means THOR has a small tooling package that is easy to deploy and retrieve. It also means it can provide targeting heat over a short reservoir interval if required, e.g., under pumps or in complex/thin reservoirs.

THOR is highly energy efficient over 90% and can be run from renewables eliminating the carbon footprint but even if run from a traditional source the footprint is very low due to the high efficiency and low losses due to being downhole.

Since THOR is downhole it does not experience any of the topside or overburden losses that are associated with topside steam and can be extensive at over 40%. One example is an operator in the Middle East who is injected at 300 BPD 550oF steam but only achieving 230 degrees Fahrenheit water by the sand face.

Operators will sometimes deploy vacuum insulated tubing for these applications to reduce heat loss, but they are very expensive and prone to leaking especially at the joints. They also keep the produced fluid cold if there is a shutdown making restarting the well a challenge. THOR heats exactly where you want it down in the reservoir removes all these losses and costs.

Topside steam requires large volumes of treated water which is an expensive and complex logistical challenge. THOR heating is only heating the production fluid there is no additional requirement for fluid or any topside handling facilities.

Topside steam also requires constant on-site monitoring and maintenance by a team of skilled technicians whereas THOR is downhole so requires no maintenance. It will be monitored remotely by the Cavitas team and reported back to the operator at a cycle of their choosing e.g., monthly.

Topside steam requires injector and produces pairs which means that the operator will not see a production increase until the hot injection fluid has swept towards the producer which can take months if not years. THOR is heating within the production well so the near well oil gets hot almost instantly, the production rate will increase in hours or days speeding up the return on investment.

In comparison to traditional thermal EOR methods which are generally inefficient, carbon intensive and large in terms of scale of infrastructure, THOR heats fluids downhole and with a high (>90%) power to heat transfer efficiency. This compares favourably to the 61% to 85% heat efficiency of cable heaters, greatly improving the energy balance and assisting in unlocking viscous fluids.

THOR has a small topside equipment footprint so is much less intrusive on the eye than tradition steam generation facilities and their associated pipelines and THOR is suitable for offshore or remote environments, unlike steam generation.

Maximum temperature

Currently the maximum wellbore temperature is 260 degrees Celsius with the limiting factor being the motor. Cavitas is working extensively with their motor suppliers especially ones that specialise in Canadian SAGD applications and expect to be able to increase that to 300 degrees Celsius (or higher) in the coming months.

Maximum power

Currently the maximum power is around 700 kW although Cavitas is exploring options with their motor partners to increase this over 2 MW. As an example, 700 kW will heat 2000 BPD of oil by 90 degrees Celsius.

How is it deployed?

Just requiring a standard workover crew, THOR can be deployed on the bottom of the production tubing. This allows the artificial lift such as a rod pump to sit in the tubing above, meaning THOR can heat the produced fluid before it enters the pump inlet aiding the lift to the surface, helping pump efficiency, and run life.

THOR is powered by a downhole motor with motor cabling is banded to the outside of the tubing as it would be with an ESP. THOR has a high energy density so is a short tool (typically under 30 ft), it can also flex at the joints between modules allowing it to navigate severe doglegs if deployment in horizontal section is required.

Cavitas is working with their deployment partners on the potential of a rigless deployed THOR in the future that could go in through tubing on a slickline meaning only an intervention crew is required.

Where to place the THOR vs. perforations, and why?

THOR is best placed over the perforations for the maximum benefit, it will achieve all the points below include those relating to the pump:

- Reduces in situ Oil Viscosity, can more than double production

- Reduce bottomhole flowing pressure

- Wellbore heating increases effective wellbore size with heat penetrating up to 15-20m into the reservoir, the pressure front can be double that see THOR influences up to 40m

- Increases near wellbore permeability by expanding reservoir pore throats

- Removes near wellbore ‘skins’ e.g., waxes

- Reduce water cut by improving mobility ratio

THOR can still be effective if deployed above the perforated section below artificial lift it will:

- Reduce bottomhole flowing pressure, can more than double production

- Minimize wax and asphaltene formation

- Alleviate pump ‘rod float’

- Improve pump efficiency and run life

- Reduce emulsions

- Reduce topside separation time

What is the cost?

Significantly cheaper than topside steam due to all the reasons Cavitas has explored, with no requirement for additional topside facilities like water treatment, no need for expensive operational technicians or Vacuum Insulted Tubing.

Cavitas’ innovative rental model reduces up front capital costs means that operators can see a return on their investment in under 50 days. If deployed during a standard workover for the pump for example the capital cost is even lower. The day rate will depend on several factors including the power and size of THOR required but will always be priced to ensure the operator receives significant values and typically operators on a ‘no cure, no pay’ basis.