Entech to Introduce Fantom™ Products to the Romanian Market

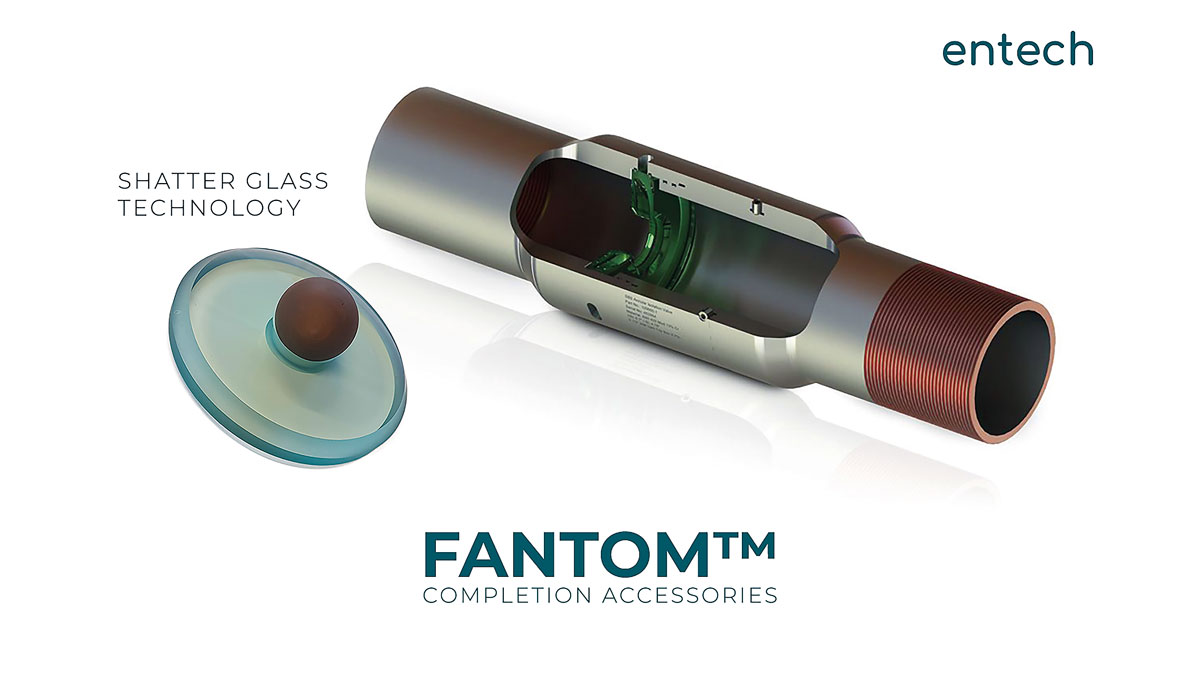

In 2019, Entech introduced the industry’s first and only glass ball seat as part of their newly released product line, Fantom™ Completion Accessories. The patented Fantom™ products rely on Entech’s proprietary glass that can withstand shocks during handling and well operations, while ensuring complete disintegration after being activated.

Kenneth Tunes, CEO of Entech, describes the motivation behind the Fantom™ shatter ball seat. “Glass is a great material for temporary barriers because it is chemically inert, high strength and breaks into tiny particles when activated. Most glass solutions require the completion string to be run closed-ended, but our Fantom™ shatter ball seat allows circulation and auto-fill while running in hole.”

The first step to developing a reliable glass ball seat was to establish the performance properties of various glass geometries. A single layer glass disk sees bending stress caused by applied pressure, but a glass ball seat will also see radial forces due to the contact area and angle of the ball. “We were curious if point loading and hoop stress would cause the glass to fail in tension,” says Entech’s CTO Jan Tore Tveranger. “Surprisingly, one of our early experiments confirmed a ball seat geometry that was equally strong to a traditional glass disk and also withstood ball impacts at high velocities”.

The next phase of development focused on expanding the portfolio by prototyping complete tools and characterizing performance of different ball materials and coatings. Entech now provides solutions for tubing sizes from 2-3/8” to 7”, suitable for both water- and oil-based fluids, with tailored ball-dissolution onset times.

Continued research led to a glass design capable of withstanding pressure differentials over 20,000psi and the recent qualification of Fantom™ products to 400˚F. “Although these ratings may be overkill for many applications, we want our customers to appreciate how versatile the Fantom™ products are and engage us to recommend solutions for their specific needs,” says Kenneth Larsen, Entech’s Fantom™ Product Line Manager.

Uses for the Fantom™ technology include intervention-less packer setting, temporary well barriers, casing, and liner flotation, sliding sleeve activation and hydraulic setting port isolation. With more than 200 successful installations of the technology, Entech has proven the reliability and cost saving advantages of the Fantom™ product line.

In 2020, Dosco PetroServices signed an agreement with Entech to introduce Fantom™ products to the Romanian market. If you wish to receive more information about this completion accessory, visit dosco.ro or contact your Dosco representative.