The Role of Wellhead Compressors in Oil and Gas Field Production Optimization

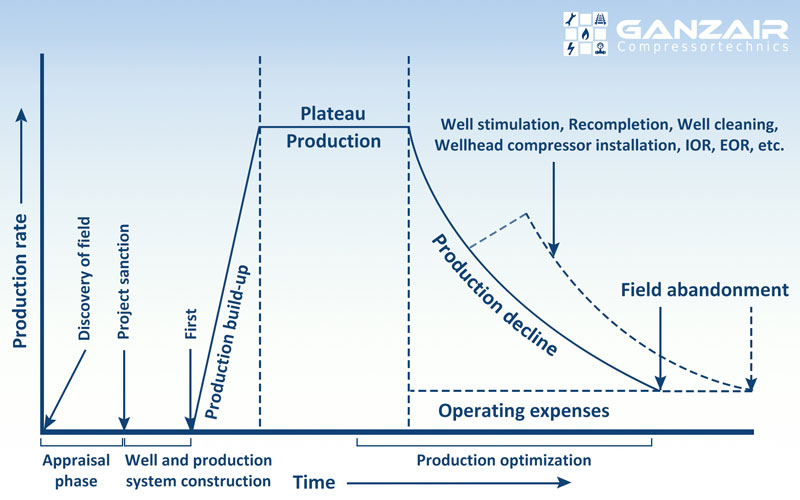

Along the life span of an oil or gas field, as plateau production progresses, reservoir energy and pressure decrease. This natural tendency leads to challenges in reaching the production limit—occasionally a long time before closing down of the oil/gas field would become necessary. In these cases, certain production optimization (or further field development, IOR, EOR) activities can maintain efficient production and prolong the life span of the field.

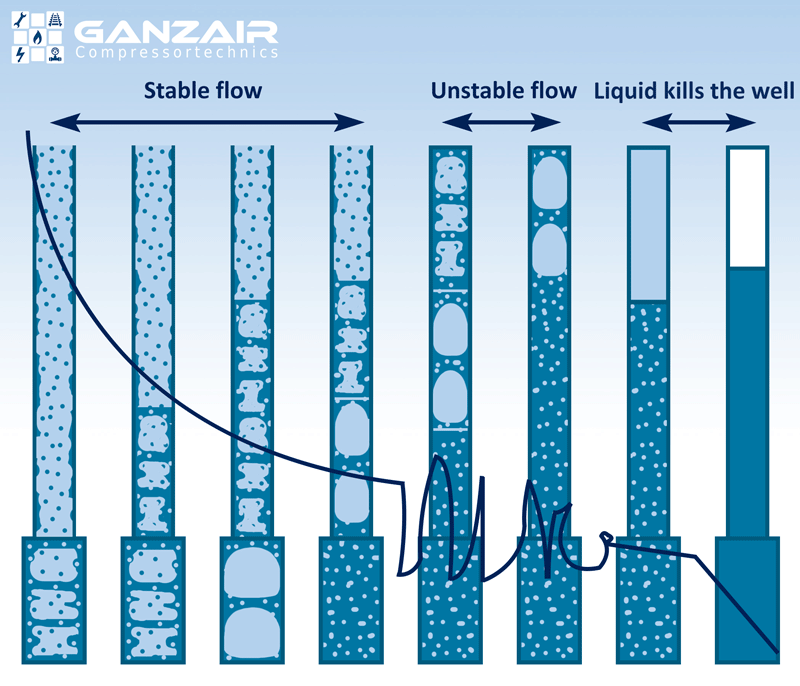

Today, cost-effective production optimization and field development solutions are broadly available. As these investments positively affect production and field life, they bring multiple return to the investors. One of the most effective and easiest optimization solutions is the installation of wellhead compressors. In case of gas wells, decreasing high gathering pressure can lead to significant production results, which can happen by using a lower stage (booster) compressor or a wellhead compressor. If the aim of the wellhead compressor installation is to increase the technical gas reserve, it will be called gasfield development activity. However, when the application of the wellhead compressor is targeted to avoid the liquid loading of low pressure gas wells (reaching of critical gas velocity), production optimization is taking place.

On the other hand, further production optimization tasks can be deployed as well, such as: well cleaning, perforation modification, stimulations, artificial lift, production tubing replacement, etc., either to substitute or to complement and expedite the efficacy of the wellhead compressor installation. In general, the investment costs of compressors are similar or slightly higher compared to other production optimization tasks (depending on the size of the compressor, pressure, and the complexity of task), however, in case of a gathering station, more wells can be connected to one (booster) compressor. If the wells do not have too long flowlines, the wellhead (booster) compressor can be placed in the nearest gathering point. Therefore, decreasing gathering pressure can be used cost-effectively in the case of depletion drive and weak waterdrive gas reservoirs.

Nodal Analysis

Before compressor procurement, a deep and complex feasibility study should be made about the reservoir, the well(s), and the gathering system (Nodal Analysis). In this case, further production problems (liquid loading, bottleneck, liquid slug hit) can be easily eliminated by the operator company.

As Prof. Zoltán Gyulay – the First Dean of Oil and Natural gas Department of University ofMiskolc – said: “Oil fields never die“~55% – 75% of the oil resource stay into the conventional reservoir rock after the field abandonment, ~10% – 45% of the gas resource also stay into the conventional reservoir rock after the field abandonment. It is up to us we could find the appropriate technology to increase of recovery factor of the petroleum reservoir. One thing is sure the compressors always needed in the enhanced gas production and/or transportation technology.

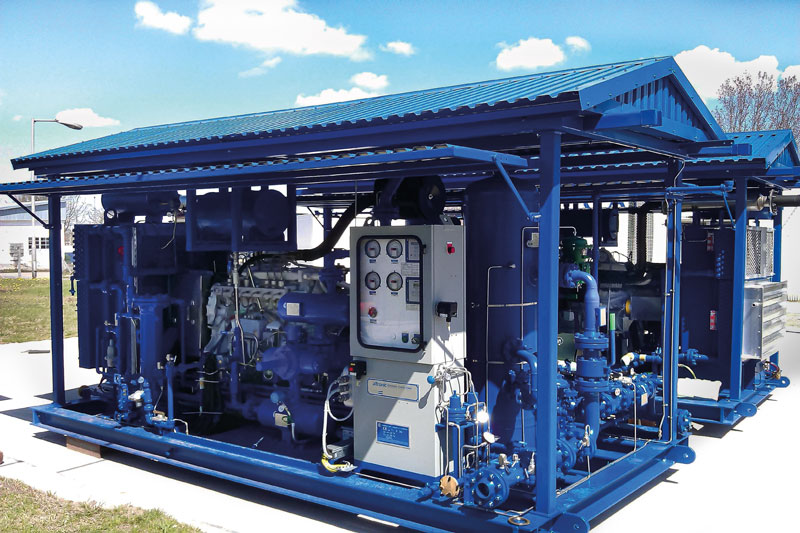

Ganzair has gained significant expertise in wellhead compressor technology during the previous decades. Wellhead compressors can be made out of more compressor types. Generally, screw compressors, reciprocating single or multistage compressors are used as wellhead compressors. In Central and Eastern Europe mainly reciprocating compressors are applied as wellhead compressors due to the popularity of this technology.

Reciprocating wellhead compressors could be electric motor driven (rarely, because electricity is usually not available in the well), gas engine (separable) driven, or integrated gas engine driven. The separable motor/engine compressors are high speed compressors (900–1800 rpm), while the integral compressors are low speed compressors (200–600 rpm).

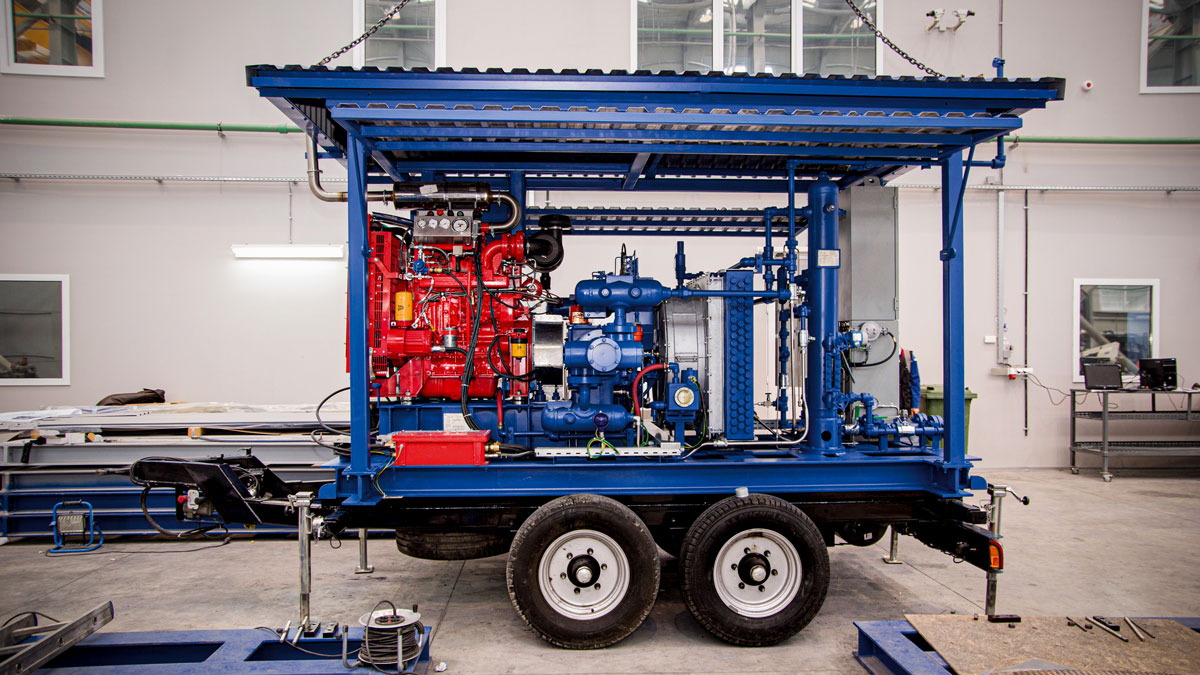

- Separable units are skid mounted and self-contained, or even trailer mounted to help the mobility. They are easy to install, offer a relatively small initial cost, are easily moved to different sites, and are available in sizes appropriate for field gathering—both onshore and offshore. However, separable compressors have higher maintenance costs than integral compressors

The American Petroleum Institute (API) has produced two industry standards, API Standard 11P and API Standard 618, which are frequently employed to govern the design and manufacture of reciprocating compressors.

- Integral compressors. The term “integral” is used because the power cylinders that drive the compressor are mounted integrally with the frame containing the compressor cylinders. Integral units run at speeds of between 200 and 600 rpm. They are commonly used in gas plants and pipeline service where fuel efficiency and long life are critical. Integral compressors offer high efficiency over a wide range of operating conditions and require less maintenance than the separable units. They have the highest initial installation cost.

Rotary positive displacement compressors, such as vane and screw compressors, are applied as wellhead compressors as well.

- Vane Compressors. The vane-type compressor consists of a cylindrical rotor with longitudinal slots in which radial sliding vanes are fitted. The rotor is positioned eccentrically within a cylindrical housing. The spaces between adjacent vanes form pockets of decreasing volume from a fixed inlet port to a fixed discharge port. Compressor inlet and discharge valves are not employed in the design. A vane compressor always compresses the gas to the design pressure defined by the manufacturer, regardless of the pressure in the system in which the compressor is discharging.

- Screw Compressors. The screw compressor, also known as a helical-lobe or spiral-lobe compressor, is a positive displacement rotary design that compresses gas between intermeshing helical lobes and chambers in the compressor housing. Screw compressors do not use valves. Their compression ratio is determined by the wrap angle of the lobes and the location of the opening edges of the discharge port. Of the various compressor types, screw compressors are best able to accommodate liquid carryover.

A screw compressor generally provides greater flexibility during the well lifecycle, because it can operate more effectively in wide flow ranges and under higher compression ratio than single stage reciprocating compressors.

The multi-stage reciprocating compressors have higher compression ratio than single stage ones. The cost of entry is lower than that of a screw compressor, but the operating cost of a screw compressor is lower. Wellhead compressors require precise design (sizing) if they are to be applied to the wellhead, because the well gas and liquid production and pressure conditions in the well lifetime must be continuously satisfied. A further disadvantage is that the use of a suitable slugcatcher is essential for the operational safety of the compressor.

In that case, more cost saving can be achieved by the placing of wellhead compressor on the manifold as a booster compressor, in order to decrease the gathering pressure of the whole system. In this case, the compressor can help produce multiple wells and the high velocity liquid slugs can efficiently be separated from the low pressure gas.

(The above mentioned compressor technology descriptions are based on Petroleum Engineering Handbook).

About Ganzair

Ganzair LLC. has delivered successful wellhead compressor projects in 3 countries (Romania, Serbia, Hungary) since 2008. The company, apart from Nodal Analysis, manufacturing, and installation, has also been responsible for servicing and repairing. In addition, Ganzair organizes operator trainings after delivery and pre-commissioning as well.

Wellhead Compressor

Below two wellhead compressor projects are explained, which successfully improved gas production. The first one was deployed in both gas and oil fields, while the second project optimized solely oil production. Well unloading compressors can assist in the start-up and intermittent operation of liquid loaded gas wells or/and inflow-problem oil wells if the design of well completion allows to connect unloading injection. These units are small, low-capacity, high-pressure, multistage reciprocating compressors mounted on a small trailer. Ganzair’s easy-to-move, trailer-mounted compressors are designed and delivered on demand.

Our company manufactured six portable, gas engine driven, one stage reciprocating wellhead compressors (with 60 kW shaft power) blowcase separator to Hungary. To Austria five pieces of portable, electric motor driven, one and two stage reciprocating wellhead compressors (with 160/315 kW shaft power). To Romania two pieces of portable, gas engine motor driven, two stages reciprocating wellhead compressors (with 70 kW shaft power). Furthermore, several gathering station booster electrical and gas engine driven booster compressors (30 – 760 kW) work in Serbia and Hungary.

Casinghead compressors are usually used to help artificial lifted wells like electric submersible pumped wells, PC pumped wells, and rod pumped wells, where formation gas is required to be separated downhole and then transported through the annulus. Often the compressor discharge is routed to either a booster or to a low-pressure gathering system. Like vapor recovery compressors, casinghead compressors operate with low suction pressures, high compression ratios, and low gas throughput rates.

If your company’s oil/gas production needs optimization, and you think Ganzair’s wellhead compressor solutions could benefit the process, do not hesitate to contact us ganzair@ganzair.com.

By Attila Timák, technical support engineer