CorPower and OPS Primed for ‘Industry Advancing’ Wave Energy Project

CorPower Ocean and OPS Composite Solutions are primed to deliver an ‘industry advancing’ wave energy project after securing close to EUR 500,000 from EEA Grants.

The Portuguese-Swedish wave energy developer and Norwegian engineering firm will join forces for the COMPACT (COMposite Pressure cAsing for CosT) Project, combining sector leading Wave Energy technology with low-cost composite design and fabrication processes from the offshore industry.

Financial backing comes from Iceland, Liechtenstein, and Norway under the EEA Grants ‘Blue Growth Programme’ – which is committed to stimulating ‘blue economy’ innovation, creating jobs, and driving growth for SMEs.

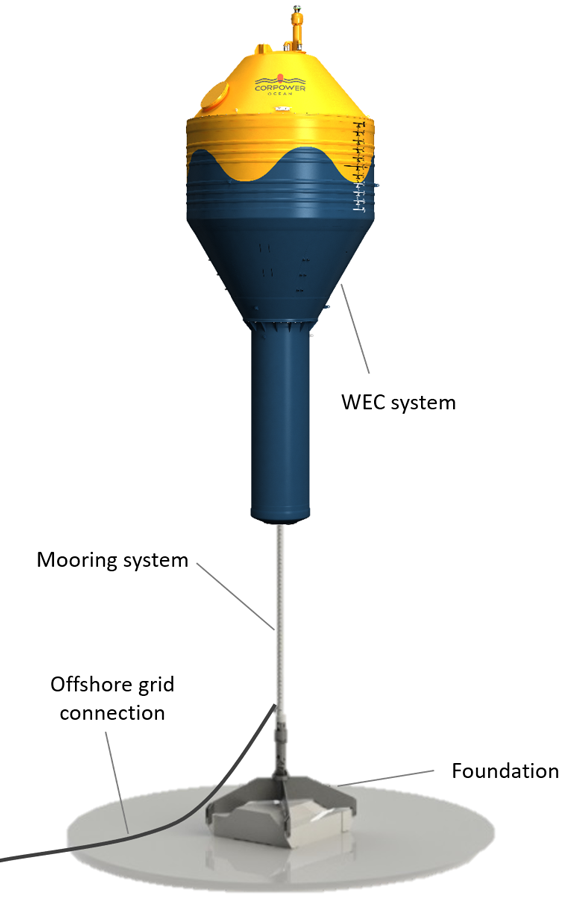

The COMPACT Project aims to boost the performance and slash costs of CorPower’s next generation WECs (Wave Energy Converters), which will shortly enter the flagship HiWave-5 demonstration phase in northern Portugal.

CorPower Portugal Country Manager Miguel Silva said the latest development marks another significant milestone speeding up the process to commercialization.

“The COMPACT project combines CorPower’s world-class WEC design knowledge with OPS’ vast experience in composite pressure vessels for offshore applications,” he said. “Together we are aiming to develop new technology addressing two common challenges experienced in state-of-the-art wave energy technology – weight and price. The process will involve developing, testing, manufacturing, and certifying an innovative light-weight pressure casing (cylinder), which is a key component of our WEC system. By making the WEC significantly lighter and using cost-effective materials and production technology, the COMPACT solution aims to increase energy efficiency while decreasing cost of energy.”

“We are proud to be a Partner to CorPower in this industry-advancing project. We strongly believe that the combination of OPS’s extensive experience with composite materials, and CorPower’s advanced technology, will bring this project closer to a successful industrial future,” OPS Composite Solutions General Manager Reidar Anderssen said.

The COMPACT Project will actively contribute to the Portuguese Industrial Strategy for Ocean Renewable Energies. Ocean renewable energy has the potential to supply 25pc of Portugal’s annual power consumption, while the sector could generate EUR 254 million in investment, EUR 280 million in gross value added, EUR 119 million in trade and 1,500 new jobs by 2020, according to the strategy.

About CorPower Ocean

CorPower Ocean brings to market, a new class of high efficiency Wave Energy Converters (WECs) enabling robust and cost-effective harvesting of electricity from ocean waves. The design principle is inspired by the pumping principles of the human heart and offers five times more energy per ton of device compared to previously known technologies, allowing a large amount of energy to be harvested using a small and low-cost device. The CorPower WEC’s unique ability to become transparent to incoming waves provides survivability for the WEC in storm conditions.

CorPower’s is headquartered in Sweden, with offices in Portugal, Norway and Scotland. The company has received broad backing across Europe, with funders including EIT InnoEnergy, the European Commission, the Swedish and Scottish Governments, Midroc New Technology, ALMI Greentech fund and additional private investors.

CorPower’s HiWave-5 Project

CorPower’s HiWave-5 Project continues in northern Portugal following a decade of product development and three decades of research on wave hydrodynamics.

The Swedish-headquartered developer is currently fabricating its first commercial scale C4 WEC – 9x18m, weighing 60 tonnes with a 300kW power rating. Dry testing is scheduled for Spring 2021, before ocean installation in the second half of 2021. This will be followed by a cycle of testing and design updates to further develop the commercial stage C5 machines. A total of three C5 machines will then be installed in Aguçadoura in 2023 to form a grid-connected pilot array and secure type certification.

The latest TUPEM announcement comes shortly after CorPower announced a new 16 MEUR (USD 18.1m) R&D, Manufacturing and Service Centre in Viana do Castelo.

CorPower’s verification process

CorPower’s structured five-stage product verification program is recognized as best practice in the sector. It includes verifying step-by-step that the business case is supported by the physical and economical metrics in each stage from small scale models (since 2012) to full scale array product (by 2024). Dry testing each machine in controlled simulated wave loading on-land to debug and stabilize the machines prior to ocean deployment is a key part of the strategy. It includes a rigorous Certification process with DNV-GL and independent validation of device performance by EMEC and WavEC.

What Makes CorPower technology unique?

The CorPower Wave Energy Converter (WEC) produces 5 times more electricity per ton (>10MWh/t) than any other known wave technology by combining storm survivability and strongly amplified power capture in regular sea conditions.

The WEC has four significant patented features:

- a) Pneumatic pretension system. Makes the device transparent to storm waves and brings down the required materials by 40% compared to a conventional gravity balanced WEC, reducing CAPEX.

- b) WaveSpring phase control technology, providing 300% increase in Annual Energy Production (AEP) for a given buoy size.

- c) Cascade gearbox technology, enabling robust conversion of the amplified linear motion into rotation with low losses.

- d) Composite hull technology, eliminating corrosion issues from salt water and provides long lifetime.

CorPower WECs can harvest the same amount of Annual Energy from a buoy with 1/10 volume compared to conventional point absorber WEC. As comparison, a 300kW CorPower WEC has a size of 9x18m and weighs 60 tonnes, where other wave devices may have dimensions of 100s’ of meters and several thousand tonnes for the same capacity. Getting large amounts of electricity from a small device significantly reduces CAPEX. The compact lightweight devices are also less costly to transport, install and service, bringing down OPEX.