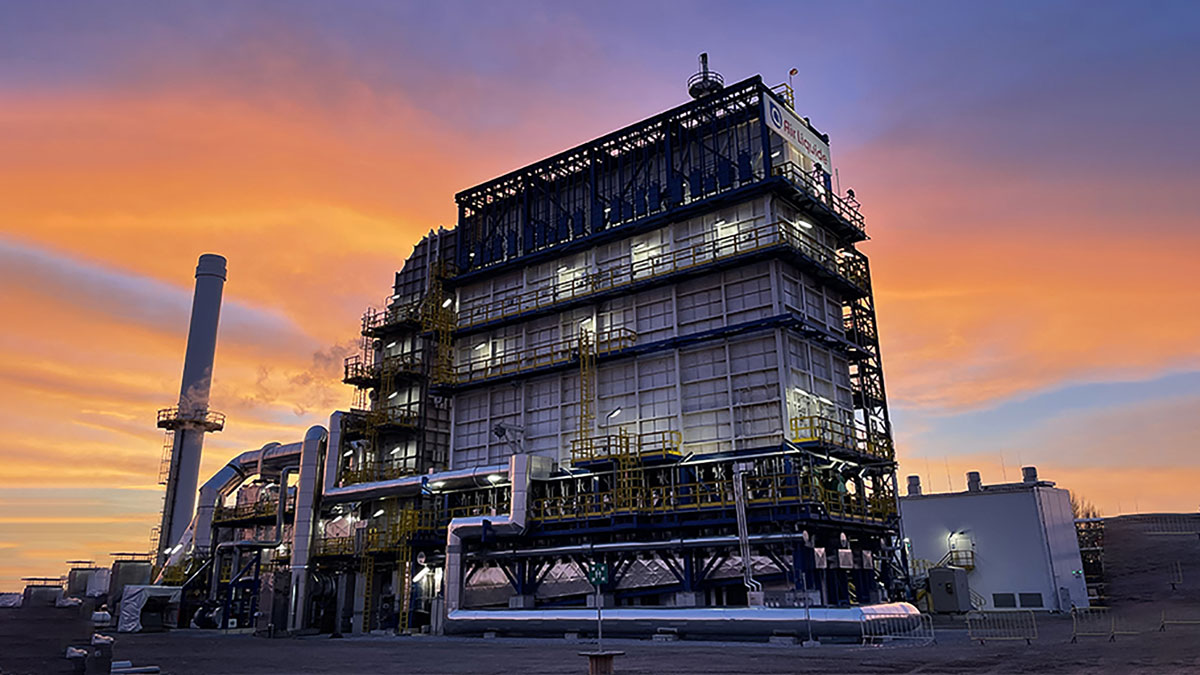

Air Liquide’s Next Generation SMR-X Hydrogen Plant Start-up

As of April 22, Air Liquide’s high-tech SMR-X hydrogen plant — located on the Covestro site in the Antwerp port area — has officially been brought into operation.

What makes the SMR-X so special — compared to a traditional SMR (Steam Methane Reformer) — is that it does not produce excess steam. The result is better energy efficiency and lower CO2 emissions. Covestro will also uses some of this CO2 as a raw material in ammonium carbonate production.

Cleaner hydrogen

Covestro also purchases around 40% of the hydrogen produced. The remaining 60% goes to other customers via the Air Liquide pipeline network.

Using the SMR-X plant, Air Liquide can leave a smaller carbon footprint when supplying hydrogen to its customers. The plant will produce around 56,000 m3 of hydrogen per hour, greatly increasing hydrogen availability in the Antwerp area.

Overcoming challenges

Plant construction has become more challenging than anticipated due to the unforeseen restrictions surrounding Covid-19. This has naturally led to delays but, thanks to the team’s flexibility and efforts, the delays have been very limited.

Initially, specialist Air Liquide personnel from Germany, Poland, Saudi Arabia, Spain, Kazakhstan, and Italy were due to arrive to help start up the plant. But because of Covid-19 travel restrictions, this wasn’t feasible in the end. Thanks are due to the flexibility and commitment of Air Liquide’s Engineering and Construction team, as well as Covestro and the contractors involved, for the plant’s construction and successful start-up with no major delays. At the end of 2020, the first industrial production (FIP) milestone was reached.

The SMR-X factory will mean that Air Liquide contributes to the energy transition and the development of transport applications for hydrogen in the Benelux. The project therefore represents a perfect fit for the Air Liquide Group’s sustainability objectives.

And best of all: the completed SMR-X unit’s early test results demonstrate that the plant is performing even better than anticipated.

Key figures

- Production: 56,000 m3 hydrogen/hour

- Cost: €82 million

- Construction: > 400,000 person-hours

- Hydrogen purity: 99.99%.

- Factory surface area: 6,000 m2