EOT Delivers Cost Reductions to Upstream and Midstream Operation Centres with Closed-Loop AI

Embassy of Things (EOT) has released AI Edge Controller which enables the use of trained machine learning models to perform real-time predictions and anomaly detection at the edge of operation centres and uses closed-loop, event-response operational action to instantly avoid expensive downtime and increase production output.

“EOT is excited to deliver an essential breakthrough for making self-optimizing industrial plants a reality by closing the loop of analysing operational data in the cloud and operationalizing AI insights at the edge in collaboration with AWS, Xecta, TensorIoT and CTG,” comments Matt Oberdorfer, CEO and President of EOT.

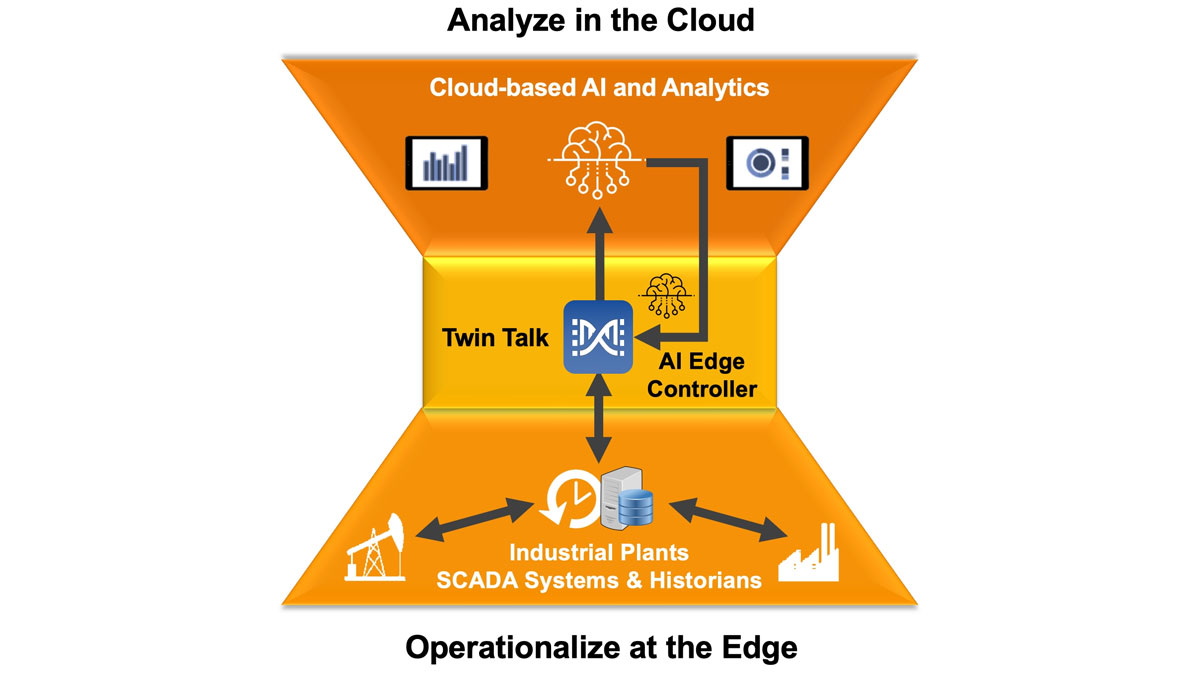

During the training phase of machine learning (ML) models, large data sets of sensors are needed to optimize their prediction quality. This requires significant compute and storage power which is only available in the cloud. However, the need for anomaly detection and self-optimization occurs at the operational edge where there is no compute, storage, or internet connection. EOT’s AI Edge Controller’s patent-pending technology serves as a bridge by delivering the rather small, trained ML models from the cloud to the edge. This is where EOT’s Twin Talk’s Operational Insight Engine streams real-time operational data through the trained ML models to instantly detect equipment abnormalities, diagnose issues, reduce false alerts, self-optimize production, and avoid expensive downtime by acting before machine failures occur.

“We are collaborating with EOT to leverage AI Edge Controller and TwinTalk as a part of the AWS production operations solution suite to support customers in their efforts to add incremental production, visualize and minimize rogue emissions and reduce lease operating expenses,” says Sid Bhattacharya, Worldwide Head of Energy Solutions at Amazon Web Services. “EOT’s solution is a significant leap in operational technology modernization – it helps customers make business-critical decisions real-time as opposed to the traditional reactive approach.”

AWS’s Production Monitoring and Surveillance solution is a Production Data Lake and Edge Software that liberates operational data from legacy SCADA and Historian infrastructure to deliver real-time production and equipment surveillance, GHG emissions monitoring, and predictive maintenance.

TensorIoT is an EOT Strategic Alliance Partner delivering complete end-to-end products and solutions in IoT, data engineering, machine learning, and artificial intelligence. “TensorIoT builds AWS Cloud-based solutions to derive valuable business insights from on-premises historian and SCADA system data,” said Ravikumar Raghunathan, CEO of TensorIoT. “Working with EOT and integrating TwinTalk with our solutions expedites the process of bringing value to our customers. We are excited about AI Edge Controller’s capability to leverage machine learning at the operator on-premise level.”

CTG delivers digital solutions across the oil and gas industry that accelerate digital transformation “CTG’s partnership with Embassy of Things reflects our ongoing commitment to deliver digital transformation to the energy sector,” said Barbara Locklair, Managing Director of CTG’s Energy Solutions. “CTG’s deep energy domain experience and IT technical expertise combined with EOT’s technologies such as AI Edge Controller and TwinTalk is transforming the energy sector by reducing the carbon footprint, lowering costs, and increasing production.”

Xecta’s cloud-first digital platform utilizes a fusion of AI, domain physics, and modern computing to solve complex engineering problems related to operational optimization at scale that enable energy operators to create extraordinary operational and capital efficiency. “Our customers want to use the next generation of autonomous models that self-calibrate to real-time performance data from a multitude of sensory inputs to optimize asset performance as a whole,” says Sanjay Paranji, CEO at Xecta Digital Labs. “We are excited about EOT’s AI Edge Controller and Twin Talk’s Insight Engine. It’s a true milestone for implementing a cognitive twin, because it enables to automate, manage, deploy and use of cloud-trained AI models in closed-loop operation centres.”

EOT provides secure, scalable, and intelligent ETL++ and Operational Data Management Systems designed to liberate operational data from historians and SCADA systems for cloud analytics and using insights for enabling self-optimizing industrial plants. EOT is helping customers in energy, manufacturing, and transportation to capitalize on production, asset and resource optimization and cost savings by enabling event-driven, real-time architectures in the cloud and operational intelligence at the edge.