Energy Solution’s New TR1300 Operational at World’s Largest Utility-Scale Battery Energy Storage Project

LG Energy Solution, South Korea’s leading manufacturer of advanced lithium-ion batteries, recently supplied Vistra’s Moss Landing Energy Storage Facility with its latest innovative Transportable Rack (TR1300). The 300MW/1.2GWh facility, the world’s largest battery energy storage project connected to the power grid in December 2020, was developed by Vistra, a leading integrated retail electricity and power generation company based in Irving, TX.

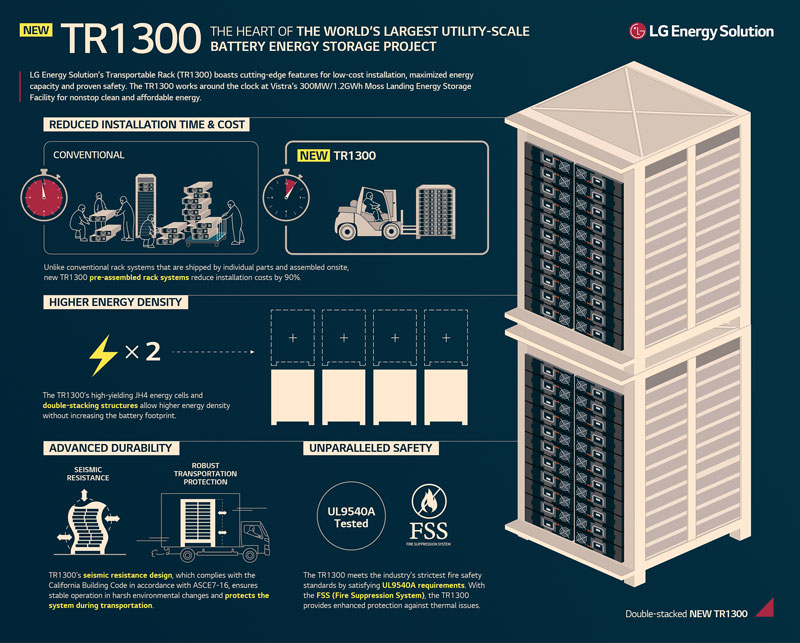

To bolster the reliability of California’s power grid and support increasing use of clean renewable energy resources, the Moss Landing project uses over 4,500 TR1300 battery racks supplied to Vistra by LG Energy Solution. Setting a new standard for battery rack systems, the TR1300 delivers more value to customers by maximizing safety and energy density, while saving construction time and costs by greatly simplifying installation.

Unlike traditional methods in which racks and battery packs are shipped separately and assembled onsite, the 22-pack TR1300s are pre-assembled at the factory prior to shipment to reduce construction time and associated installation costs. Factory assembly also ensure consistent quality of the assembled rack systems. Each assembled rack is tested prior to shipment to minimize the occurrence of delays during on site testing and commissioning activities.

Equipped with the company’s high-performance JH4 energy cell, the TR1300 can be double-stacked to further boost energy density. This feature enabled the full 1.2GWh of battery capacity to be accommodated within the existing Moss Landing turbine house building, without the need for major construction work.

In addition to high energy density and ease of installation, the TR1300 meets the industry’s strictest fire safety standards. Racks have also been tested to verify compliance with UL9540A (Standard for Safety Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems), to ensure any fire event is not propagated to adjacent battery racks. On top of this, the rack’s design satisfies the California Building Code following the American Society of Civil Engineers’ ASCE 7-16, assuring its stable operation even during external environmental changes such as seismic tremors. Thanks to its enhanced durability, the device also can be transported safely and securely almost anywhere.

“Under the shared goal of providing Californians with reliable, clean, and affordable energy, we’re very pleased to be working closely with LG Energy Solution and look forward to continuing our valuable partnership through Phase II at Moss Landing, which will add 100MW/400MWh to the facility,” said Claudia Morrow, Senior Vice President of Strategy and Development at Vistra. “As our country transitions to a future of emission-free electricity, projects like this are vital in ensuring reliability and supporting renewable energy growth.”

“Vistra has very aggressive plans to meet California’s future clean energy needs and so we’re delighted to have supplied our advanced TR1300 batteries for their first gigawatt-hour project at Moss Landing,” said Peter Gibson, Director of Energy Storage at LG Energy Solution in the United States. “The Vistra team is to be commended for its achievement in repurposing the Moss Landing Power Plant’s former turbine hall into the world’s largest battery storage project.”