BIOPLASTICS: The Best of the Bad

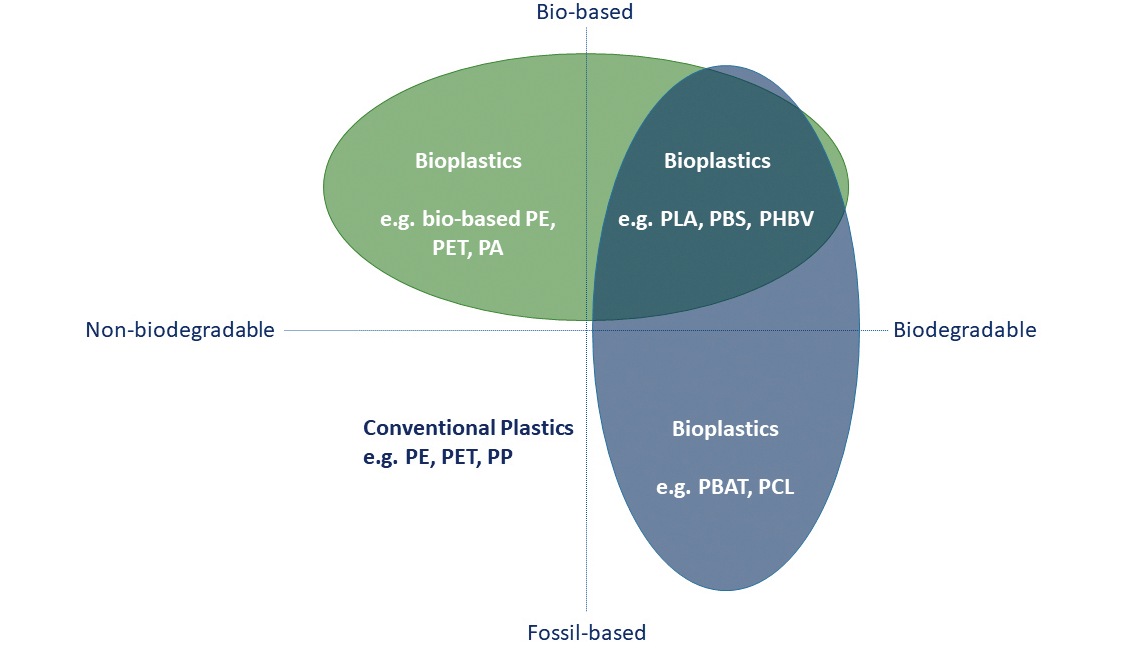

Bioplastics does not have a standardized definition and is yet a confusing term that can refer to bio-based, biodegradable, and/or compostable plastic. It can even include up to 80% fossil fuel-based plastic.

Bio-based plastic is plastic partly or entirely made from biological feedstocks such as corn or potato starch, but often still contains fossil fuels, and is functionally or even chemically identical to conventional plastic.

Biodegradable plastic is plastic that can, under certain conditions, be broken down by microorganisms like bacteria and fungi into water, carbon dioxide, and naturally occurring minerals. Biodegradable, therefore, refers to a material’s end-of-life behaviour, regardless of its component materials, which can include biological material, fossil fuels, or both.

Compostable plastic is a subset of biodegradable plastic that can fully biodegrade under the specific conditions of an industrial composting facility.

Moreover, a study by scientists published in 2020 found that: most bioplastics and plant-based materials contain toxic chemicals; cellulose and starch-based products induce the strongest in vitro toxicity; most samples contain more than 1,000 chemical features; bio-based/biodegradable plastics and conventional plastics are similarly toxic.

Plastic is unfortunately still very present in our day-to-day life. Almost 500 billion disposable plastic bags are used every year, which shows an excessive use of this material.

Since the beginning of the 1950s, plastic was an integral part of our lives. It is used in most everyday objects to the point of endangering ecosystems and human health. This consumer awareness, added to the ever-increasing legislative constraints, pushes manufacturers to find alternatives to traditional oil-based plastic. In the last fifteen years, new types of ‘innovative’ packaging have invaded supermarkets, gradually replacing packaging: these are bioplastics. It looks that they have all the benefits of oil-based plastic, without its harmful effect on the environment.

Many companies hope that bioplastics can reduce the negative impact of packaging on the environment. When bioplastics are incinerated, the amount of CO2 released into the atmosphere is equal to that fixed during their growth by the plants that serve as raw material. This is an asset compared to oil-based plastic.

The term of bioplastics is used to designate two realities: on the one hand, biodegradable plastics and, on the other hand, plastics made of biological and renewable feedstocks, such as plant matter. The latter can be biodegradable or not, depending on their composition.

Bio-based plastic and biodegradable plastic

They emerged in the 19th century, being used to make many everyday objects before being dethroned by petrochemical plastics, with much lower production costs. Accounting for only 1% of the total plastic production, bio-based plastics are currently facing a strong growth, determined by environmental concerns. However, there is no standardized definition so far and this is the whole problem. The term of bioplastic is a general term that may be confusing, as it can characterize materials with different composition and properties. Two types of bioplastics are commonly distinguished.

Bio-based plastics are made from vegetable materials, also named biomass, considered a renewable resource, unlike oil.

The ‘organic’ prefix refers to the origin of this composition of plastic but does not mean that it comes from the ecological agriculture.

Biodegradable plastics, also named ‘compostable’, are supposed to be able to decompose under the action of microorganisms (bacteria, fungi etc.) under specific controlled conditions (heat, humidity etc.).

The ‘organic’ prefix refers here to the end-of-life properties of the plastic and not its composition.

Rarer are plastics that are both bio-based and compostable plastics.

Attention, oxo-degradable or fragmentable plastics are neither bio-based plastics nor biodegradable plastics. These are conventional plastics derived from petrochemicals that contain an additive, usually metal salts, to accelerate their fragmentation under certain conditions (light, heat etc.). They are mainly used for shopping bags, and manufacturers claim the low impact they would have on the environment. But they generate a dangerous pollution for ecosystems and human health, as they are very easy to ingest. This is also why certain disposable plastics have been banned and for which new deadlines are emerging due to the Anti-Waste Circular Economy law.

Bio-based plastic and biodegradable plastic – the winning combination?

When we are talking about bio-based plastic, it is necessary to look at its composition and origin. Plastic qualified as bio-based is not necessarily composed only of resins of natural origin: it can be composed of bio-based plastic up to 68% (knowing that the minimum content in 2025 will be 60%) and petroleum plastic of 32%. In any case, this does not guarantee the biodegradability of waste at the end of its life. In January 2020, the Circular Economy Law (AGEC) established the content of bio-based material in the composition of disposable plastic bags to at least 50%.

The production and use of bio-based plastics remain indirectly and strongly linked to petrochemistry, as the so-called ‘renewable’ sources used in their composition come from industrial agricultural crops, with multiple impacts on the environment and on humans:

- International transport and oil-fuelled vehicles

- Use of pesticides and fertilizers harming the environment and human health

- Water-consuming agriculture

- Deforestation

- Soil quality degradation

- Difficult working conditions

- Mobilizing agricultural land, as global hunger kills more than 9 million people worldwide each year.

Starch and cellulose, new feedstocks

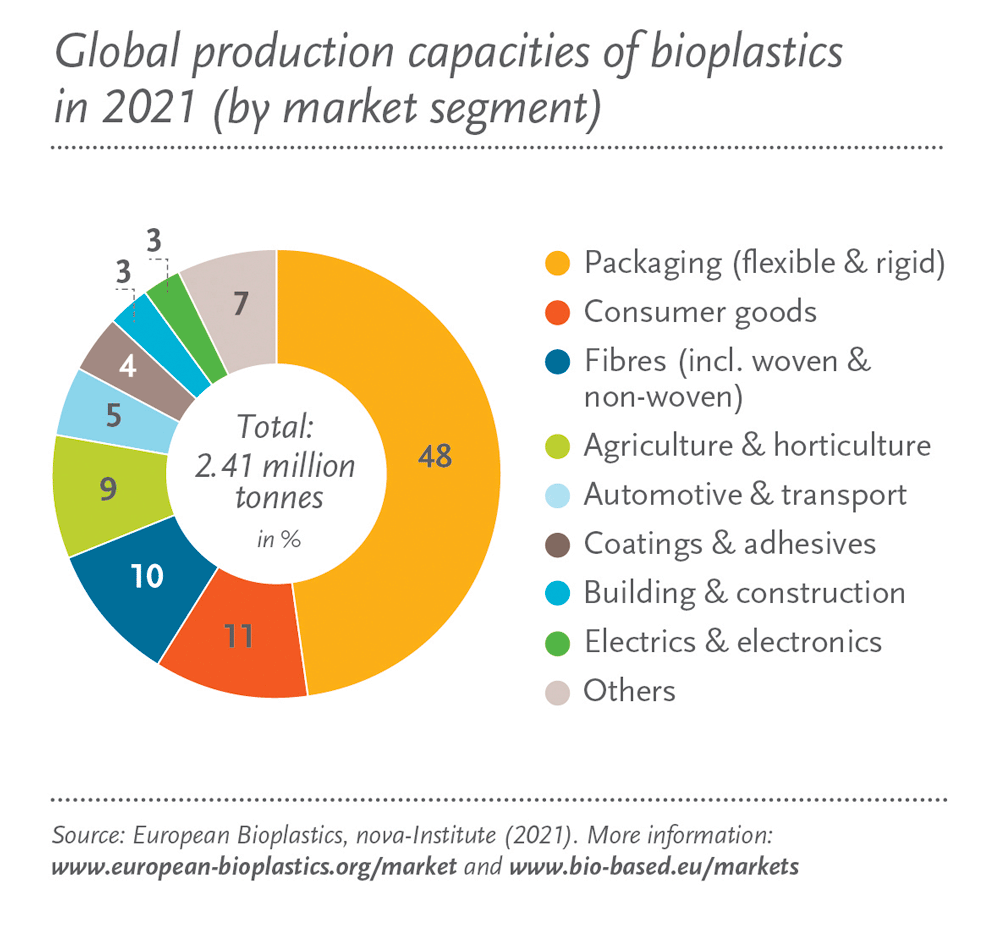

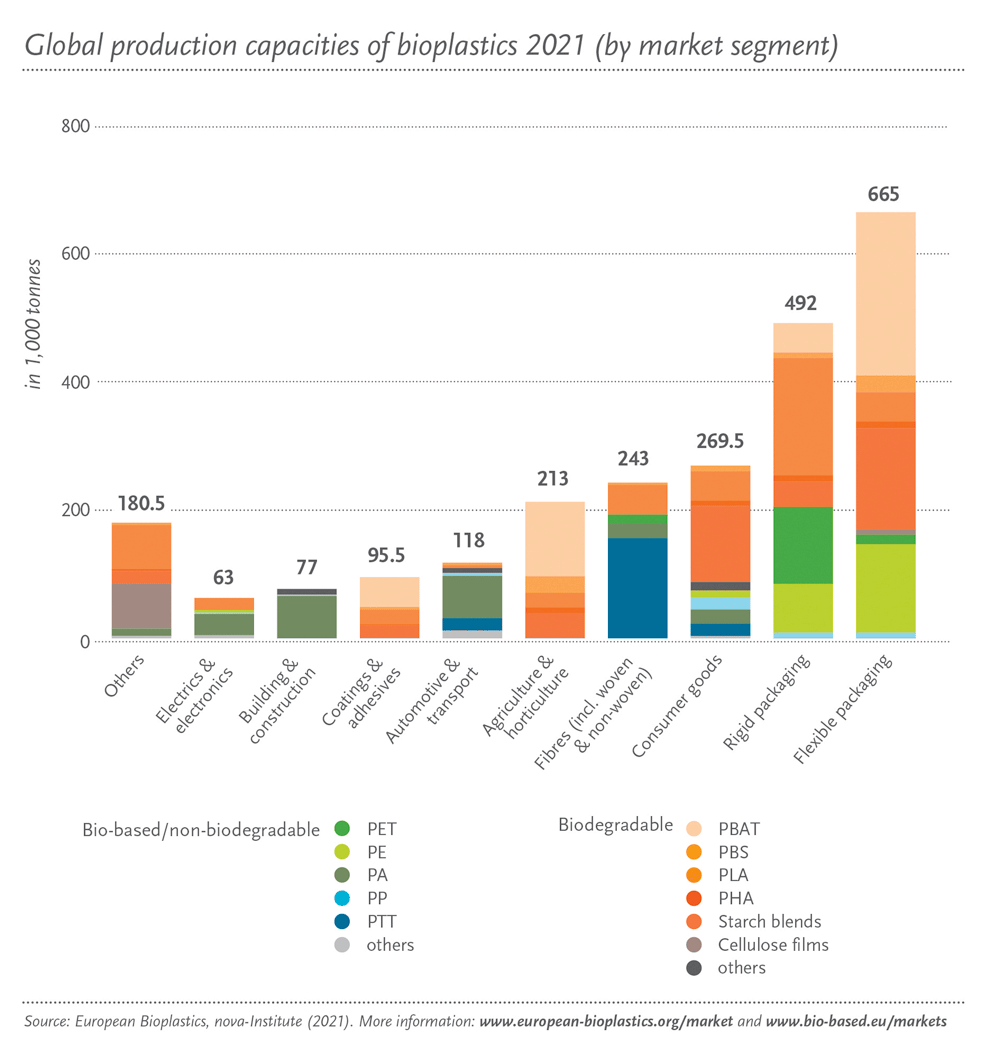

Many large companies in the food sector now use bioplastic packaging. With a market share of approximately 80%, thermoplastic starch is the most used bioplastic. Thermoplastic means that the plastic can be poured within a certain temperature range. Today, starch used as feedstock for bioplastic comes mainly from corn, wheat, potato, and tapioca. Cellulose, the most common natural polymer, is also used, being extracted from wood or plant waste to make several new types of plastics.

Other substances, such as polylactic acid (PLA) and polyhydroxy fatty acids (PHF), are also used in the composition of bioplastics. PLA is obtained by synthesizing large, long-chain polymers from lactic acid. The necessary lactic acid is obtained by fermenting sugar and starch. The latter generally come from food plants (corn or wheat). The same is true for PHF: bacteria or fungi produce thermoplastic polyesters from starch, in several steps and through biochemical reactions.

However, the ecological balance of bioplastics is not always positive.

Indeed, the plants used as feedstock for bioplastics must be watered, fertilized, and treated with pesticides. These methods are harmful to air, water, and soil. Moreover, the feedstocks used (corn or wheat, for example) are no longer available as food.

Biodegradable, a key marketing word

The term biodegradable denotes the ability of a product to break down and be effectively bio-assimilated by the environment under the action of microorganisms and factors such as humidity, heat, or the presence of water. However, the use of the term ‘biodegradable’ for a product does not say anything about the speed of this degradation or about the particular conditions, not always met, under which such as material can be effectively ‘bio’-degraded. Therefore, it does not mean in any way that the product can be thrown into the environment without consequences. This term should be avoided, often being the sign of a marketing approach of the company. The anti-waste law of 10 February 2020 also prohibits the application of the term ‘biodegradable’ to a product or packaging in the same way as the expression ‘environmentally friendly’, just as vague!

Two standards for compostable materials

The concept of compostability of plastic materials has the merit of being more precise than that of biodegradability: it designates materials likely to degrade in the presence of organic waste and in composting conditions (increased temperature, presence of specific microorganisms etc.). There are two standards to qualify plastics as ‘compost’: the NF EN 13432: 2000 standard that designates plastics capable of degrading under industrial composting conditions and the NF T 51-800: 2015 standard that designates plastics suitable for home composting.

On plastic packaging and bags, the product’s compliance with these standards is often characterized by a logo such as ‘OK COMPOST’, which guarantees compliance with the European standard 13432.

Whether or not they are suitable in theory for home composting, ADEME (French Agency for Environment and Energy Management) recommends that these compostable plastics be directed to industrial composting platforms, as it is unlikely that the conditions necessary for their degradation into individual or garden compost will be achieved.

Moreover, compostable plastics are not necessarily greener, and, above all, they are not a miracle solution to the problem of plastic pollution! Indeed, to be composted, these plastics must be sorted separately from the rest of the garbage with organic waste (food scraps) and directed to an industrial composting platform. Also, it should not represent a too large amount compared to organic waste to be able to effectively degrade. All these conditions are difficult to fulfil. This advocates for a use of compostable plastics limited to certain very specific applications, in the context of which introduction on the market is not likely to lead to sorting errors, processing difficulties at the level of composting platforms or abandonment in nature. In the end, even when composted, compostable plastics do not have specific agronomic benefits for the soil and therefore can hardly qualify as a circular economy solution, as the material is lost rather than recovered.

Attention to the origin of the material

The term bio-based refers to another category, which this time deals with the composition of the material and not the fate of the waste produced. ‘Bio-based’ means that the material was partially or completely made of resources derived from biomass (agricultural crop residues, sugarcane, potatoes etc.). This characteristic does not involve in any case the fate of waste at the end of life, which can very well be biodegradable or not.

In this regard, it is mainly about being vigilant about the proportion of ‘bio-based’ material actually present in the product (the term can be used even if the bio-based part is actually minimal in the composition) and the origin of the material used for the production of plastic. Indeed, some bio-based plastics are, for example, made from sugar cane, a plant grown far from Europe, whose cultivation is far from environmentally neutral.

Therefore, if the use of bio-based plastics can make possible to avoid part of the consumption of fossil resources, it is not an alternative to our overproduction of plastic. The quantities of plastics produced and consumed each year in the world are indeed such that their complete replacement with natural materials would have certain counterproductive effects: competition with food production, degradation of soil quality, environmental impact related to crops etc.

‘Oxo-fragmentable’ plastics

Some plastics presented as ‘green’ or ‘organic’ are in fact the so-called ‘oxo-fragmentable’ plastics, which do not degrade in the environment. Oxo-fragmentable plastics, sometimes misrepresented as being biodegradable, have a disastrous impact on the environment. Once in nature, they effectively disappear quickly from sight, but degrade into plastic microparticles, just as polluting. The European directive on single-use plastics provides for their ban.

So, vigilance is needed on ‘organic’, ‘plant-based’ or ‘degradable’ alternatives to conventional plastics. The solution to plastic pollution is, of course, above all reducing consumption and developing reusable alternatives to single-use products and packaging. Bioplastics are therefore far from being a ‘miracle’ solution.

As the name suggests, biodegradable plastics can degrade. But this term remains ambiguous, it does not say anything about the duration and conditions of plastic degradation. Most biodegradable plastics are degraded in fact under very specific conditions and in a controlled environment that only industrial composters have. They also must be collected correctly, as, at present, there is no adequate sorting bin for bioplastics. Equally, if placed in ‘home’ composters, their degradation lasts more than a year and this depending on the product. Therefore, in no case should they be thrown in nature if the biodegradation conditions are not fulfilled.

Researchers from the University of Plymouth demonstrated that the biodegradable bags were still functional after being left in the ground or in a moist environment for more than three years.

PLA plastic, a material en vogue

PLA (polylactic acid), a 100% bio-based, biodegradable, and compostable polymer, has seen explosive demand in recent years. Produced from corn or sugar cane crops, it is mainly used to make food packaging and disposable tableware. It may be perceived as a magic solution, but this bioplastic still requires a specific mix of bacteria, heat, and moisture to biodegrade. Therefore, it must be sent to a specialized industrial composting centre. However, so far there aren’t many such centres. Manufacturers thus play on this misunderstanding, of a compostable plastic, which is made on an industrial scale. It is not sorted either, as it is part of the classification of plastic families category 7 ‘other’. Even though there was an industrial sector for collection and composting, PLA plastic contains essentially carbon and not nitrogen. To produce a quality compost, it is important to have a good carbon/nitrogen ratio. However, PLAs tend to have this ratio too high, making the process slow, releasing few nutrients into the soil, and releasing carbon dioxide. This type of plastic does not improve the quality of compost and, therefore, poses no real interest for the local economy or agriculture.

Packaging and waste: a long history…

It all started in early ‘90s, when the port-city of Anvers, in north Belgium, decided to organize the collection of green waste within the European Directive ‘Packaging and Packaging Waste’.

The authorities, which considered it logical to collect garden waste in compostable bags, encountered numerous quotes from bag manufacturers claiming they were compostable without being able to verify this. So, the city turned to the main Belgian certification body to be able to choose between the offers.

This ad-hoc request gave birth to the idea of a certification system associated with a logo: OK compost and the first certificates were signed in May 1995.

The range of certified products expanded very quickly from collection bags to shopping/house bags, to food packaging and then catering items, more specifically in the fast-food sector. In fact, composting items contaminated with food residues provide a viable alternative from an economic point of view to incineration, as the presence of these moist food residues reduces a lot the energy efficiency of incineration, while improving the composting process.

Obviously, and no one can challenge this, the best packaging is the one that does not exist, but packaging is still indispensable in some cases, and it has especially a protection function. Without this protection, food would degrade too fast, especially during transit and whole on shelves. But once packaging becomes necessary and, if it cannot be reused, it should be recycled, the final solution being incineration (with energy recovery) or disposal/landfilling.

Over time, the range of compliance marks has also expanded to other environments where waste can occur, household compost (OK compost HOME), or biodegradability in nature (OK biodegradable SOIL, WATER and MARINE).

The OK compost family assumes that there is human intervention for packaging, in a composting centre or home composting, as well as a time lag concept for disintegration and biodegradation.

In contrast, the OK biodegradable family requires no intervention, nature taking care of the decomposition.

In 2006, Al Gore, former vice president of the USA and winner of the Nobel Peace Prize in 2007, published a manifesto in which he gave birth to a new idea: until now, we have dealt with the different end-of-life streams of plastics, waste treatment, but what about the origin of these materials?

This consideration gave rise – after 3 years of development – to the OK bio-based compliance mark.

The bio-based concept often creates confusion. Bio-source refers to the natural, contemporary, and renewable origin of products (= of plant origin) as opposed to fossil and non-renewable resources (= petroleum). However, it should be noted that being bio-based does not in any way confer a capacity for biodegradation of the product in question. These are two completely independent features. For example, in its most familiar form, polyethylene used to make bags is of fossil origin, but still bio-based.

The sugarcane-based version has been available on the market for several years. Nothing distinguishes these two materials from a chemical point of view: their composition is absolutely identical. Only carbon 148 allows the distinction, but none of the plastics are biodegradable.

Plastic production, 2050 horizon

World Economic Forum estimated that by 2050 ocean plastic would end up weighing more than all fish combined. And plastic particles are ingested by these fish that become human food. To slow down this trend, in 2019, the European Union decided to ban certain plastic products, especially the single-use ones. The decision was also implemented in Romania, with some delay.

An analysis published in July 2021 by a group of European environmental organizations points to the fact that global plastic production increased 20-fold over the last 50 years and that in 2050 it would be four times larger than at present. Other research shows that from 1950 to 2019, at global level, 8.3 billion tons of plastics were produced, of which 6.3 billion became waste.

European authorities adopted 3 years ago a directive meant to reduce the impact of plastic products on the environment. The directive was recently transposed in Romania, but leaves room for interpretation and imposes difficult obligations, if not impossible to fulfil in a short term for companies in the field.

Third generation bioplastic, a possible solution

Today, new polymers are being developed, benefiting from synergistic effects, or using enzymes to improve biodegradability. All these technologies create new ideas that determine the development of new approaches to cope with market changes in terms of tests, compliance assessment and market monitoring.

Third generation bioplastic may be the answer. These are plastics produced from natural materials that are not currently used (green waste, for example). Seaweed, easy to cultivate and fast growing, is also considered as a feedstock. The market for such bioplastics is growing and some manufacturers are starting to replace part of the feedstock (derived from oil) in traditional plastics with renewable materials.

Innovations that bring hope

In 2019, an English student presented a bioplastic made from fish skin and red algae. Therefore, this bio-source does not monopolize the soil, like those from corn or sugar cane. And it is also compostable, as it degrades in six weeks.

In 2020, US researchers discovered a bacterium that lives in mangroves, these tropical forests near the sea. Its name? Zobellella denitrificans ZD1. This microscopic living thing is capable of turning sewage sludge into polyhydroxybutyrate, a polymer that researchers claim is biodegradable.

In 2021, another team of US scientists developed a bioplastic made from wood waste that degrades in three months.

Romania and bioplastics

When the European Union published the strategy for reducing plastic, industry and some decision-makers insisted to introduce biodegradable plastic as an easy-to-implement alternative to traditional plastic. On the Romanian market, there are brands that produce or import bio-plastic, promoting the initiative as one beneficial for the environment. Zero Waste Europe and environmental NGOs warn however that biodegradable plastic will not solve the problem of plastic pollution.

“The industry of bioplastics uses ‘green’ arguments to position itself as the one that can accelerate the reduction of fossil fuel use and can contribute to solving the problem of plastic pollution. But there is clear evidence that bioplastics not only fail to solve many of the existing problems, but also create new ones. Due to the complex design, they disrupt the collection and recycling processes, ending up in landfills or incinerators or, worse, directly in the environment. Moreover, they could encourage dumping waste in nature, they can contaminate recycled materials and can significantly increase the costs of managing biodegradable waste. The expansion of industry increases the pressure on the exploitation of arable land, with an impact on the environment and citizens,” say the experts from Zero Waste Europe.

Directive (EU) 2019/904

Beyond the improvement of collection and recycling mechanisms, European authorities have decided to limit the manufacturing of plastic products, especially the single-use ones. Directive (EU) 2019/904 prohibits placing on the market of certain categories of products for which there are plastic-free alternatives at affordable prices.

For other plastic products, different measures apply. They include limiting the use and reducing consumption of such products and preventing the incorrect management of waste generated by labelling requirements, extended producer responsibility schemes, awareness campaigns and product design requirements.

Moreover, the directive imposes a gradual reduction of consumption of some categories of single-use plastic products by 2026, compared to the reference value of 2022.

The legislative act had to be transposed into the legislation of the EU countries by 3 July 2021, from which date the restrictions on placing the products in question on the market and marking those newly introduced on the market should also have applied. For other measures, the directive allows later application deadlines, such as 3 July 2024 (design requirements for bottles) or 31 December 2024 (extended producer responsibility measures, except for the case of tobacco, where the deadline is 5 January 2023).

Romania transposed the European directive by a Government Ordinance (Ordinance 6/2021) with a two-month delay compared to the deadline. The legislative act broadly observes the directions laid out by the European directive, especially regarding the products concerned, but presents certain gaps that must be clarified by the implementing rules or even by amending legislative acts. They include the failure to grant a transition period for merchants, in case of obligations that require prior preparation.

For example, the legislation imposes on operators that place on the market certain single-use plastic products the obligation to gradually reduce consumption, starting with 2023, so that in 2026 there is a cumulative decrease by 20% compared to the quantity placed on the market in 2022. Even if the first minimum reduction threshold (5%) applies in 2023, the legislation imposes on operators who retail such products or who use them to market their own products, two obligations that are difficult to comply with in the short term. First, merchants must provide the consumer with reusable alternatives at the points of sale, adequate and sustainable or that do not contain plastic. However, merchants’ shift to alternatives cannot be done overnight. Furthermore, it cannot reasonably be said that the operators should have known in advance that they would be obliged to provide alternatives and that they should have already been prepared with such alternatives, because the directive does not require an instrument to ensure the reduction in consumption, but provides a series of examples of possible measures, and member states must define in local legislation the measures they consider appropriate. At the same time, the legislative act introduces other complex and unclear obligations in some situations, so the authorities must develop the secondary legislation to clarify in due time all the aspects that raise question marks, to make sure that operators understand correctly, completely and in due time their obligations.