Industrial Metaverse: Shaping the Future of Work

What is the metaverse? The metaverse is seen as the inevitable evolution of the internet. But what exactly is the industrial metaverse, and how can it improve our lives?

The metaverse is a vision of what many in the computer industry believe is the next iteration of the internet: a single, shared, immersive, persistent, 3D virtual space where humans experience life in ways they could not in the physical world.

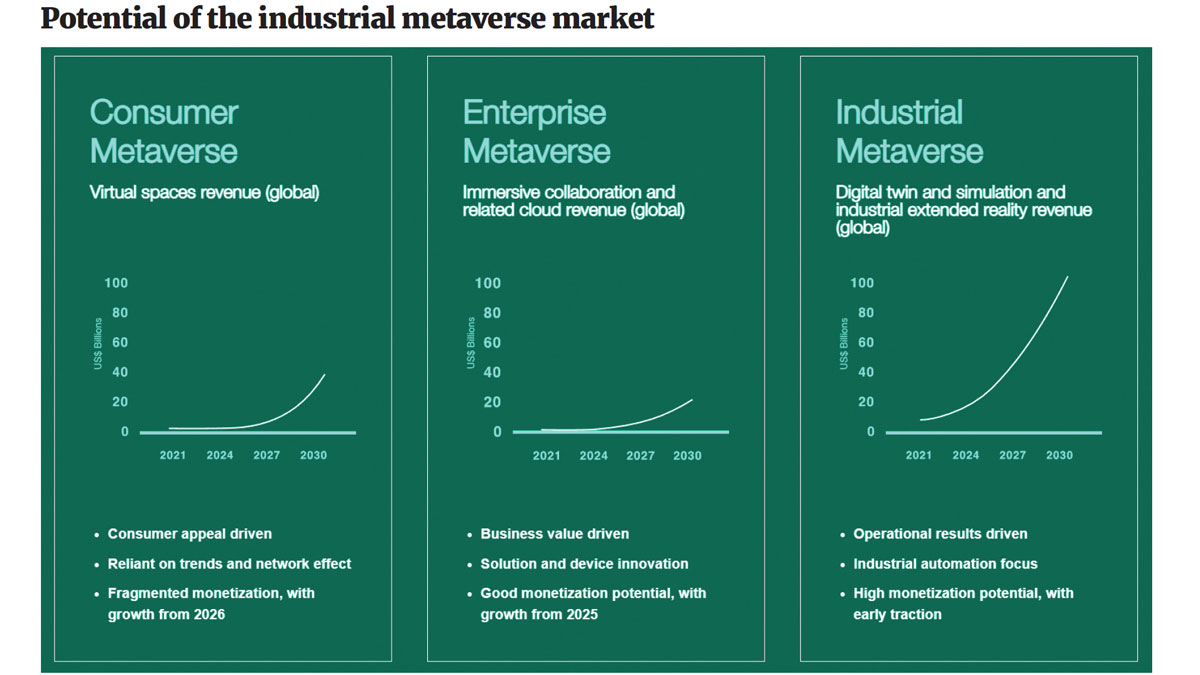

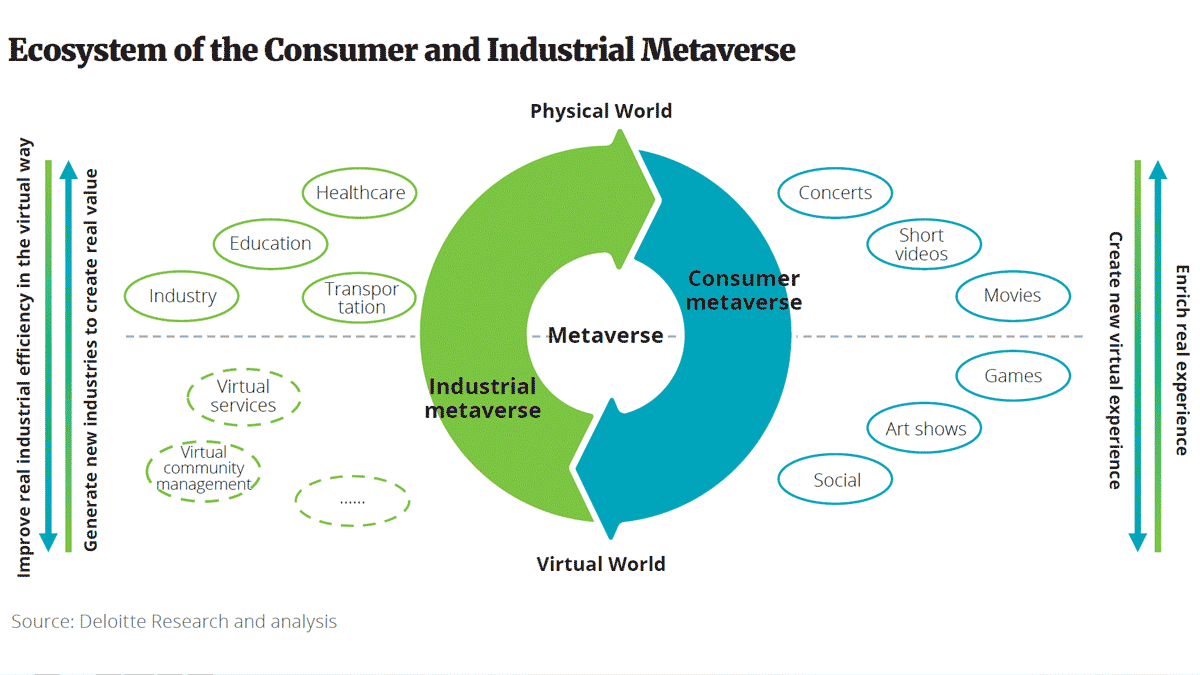

Nokia, for example believes there will be multiple metaverses and not one. Each of these will cater to different customers, companies, and communities. They fall under three broad categories: industrial, enterprise and consumer. These metaverses will have commonalities, connect to each other at varying degrees and share technologies, devices, and interfaces. Yet they will differ when it comes to applications and business models.

Industrial metaverse – some of the most significant and extensive potentials of the metaverse lie within the industrial sector that serve as the backbone of our economies. Although technologies related to the industrial metaverse are still in their initial stages, it has already become a force of business innovation. The digital twin is one such example that blends digital and physical realities and is revolutionizing many industries, ushering in cost, productivity, safety, and flexibility gains.

How can enterprises unlock the full potential of the industrial metaverse?

Even as technologists are trying to envision what the metaverse will bring for businesses and consumers, the industrial metaverse is already transforming how people design, manufacture, and interact with physical entities across industries.

“The industrial metaverse combines physical-digital fusion and human augmentation for industrial applications and contains digital representations of physical industrial environments, systems, assets and spaces that people can control, communicate, and interact with,” Thierry Klein, president of Bell Labs Solutions Research at Nokia, says.

Technologies revolutionising everyday life

Autonomous vehicles, artificial intelligence, connected objects and 3D printing are just some of the technologies revolutionising everyday life, the economy and communication.

Recently, Elon Musk unveiled a prototype of his humanoid robot Bumble C, which uses artificial intelligence to move and manoeuvre objects autonomously. The world’s richest man plans to mass-produce humanoid robots at less than $20,000 each that will perform all repetitive tasks instead of humans.

Thus, ‘new technologies’ are those technological trends that mark a change in the industrial and social pattern in the global economy. In other words, it is a set of innovative technologies for creation or development that are part of the so-called ‘digital revolution’. This revolution is the most important economic event since the beginning of the industrial revolution in the mid-18th century.

Virtual robots in the industrial metaverse

The latest developments in 3D virtualisation technologies make it possible to create ultra-realistic digital environments. But the high-precision metaverses that a young French company is developing are also populated by ‘cobots’ – collaborative robots that learn in virtual factories to work in harmony with humans.

‘Digital twins’ developed by manufacturers have long enabled them to perfectly replicate objects, machines and even simulate human behaviour in the form of avatars. These highly specialised metaverses are infinitely more precise and complex than the virtual and recreational universes currently offered by the web giants. Companies use them to reproduce workplaces, such as offices, in 3D, or to study the environmental effects of setting up a future factory, for example.

Metaverses developed by the French company SkyReal also integrate cohorts of ‘cobots’, a term that comes from the contraction of the words ‘cooperation’ and ‘robot’. The aim is to develop intelligent collaboration between people and machines, explains Hugo Falgarone, director and founder of SkyReal.

“After the development, especially for the needs of the automotive industry, of fully autonomous robots, i.e., working alone and without the assistance of an operator, companies have turned to more ‘collaborative’. These new types of machines are called ‘cobots’; the term coined in 1999 is short for ‘Collaborative Robot’. At present, we have no choice but to test these interactive robots in a virtual environment to verify their programming and that their behaviour poses no danger to the human environment. That’s why we use highly accurate metaverses to simulate a year of working in a factory and see how this collaboration between robots and humans evolves. This virtual ‘cobotics’ will make it possible to optimise interaction processes, such as ordering the robot to stop a task, for example, or to continue working, to pay attention to what is going on around it and to take into account a change in the environment. Currently, our industrial metaverses are being tested by Airbus Atlantique to validate this type of collaboration. In particular, operators will formulate their instructions to robots using gestures or voice commands. This recourse to virtual environments to develop cobotics remains, for the time being, quite confidential in the industrial sector, which nevertheless believes that cobotics will soon make it possible to collaborate, but not replace the human being, in production processes.”

With or without the ‘cobots’, professional metaverses certainly herald a future industrial revolution. But beyond the economic opportunities offered by immersive technologies deployed in companies, they must be both ethical, sustainable and in the service of workplace well-being, European policymakers warn. The EU, as with developments in artificial intelligence in business, is keen to regulate new uses of virtual reality in the workplace.

A lot of business conversations around the metaverse focus on entertainment and trade opportunities. But this is the tip of the iceberg when it comes to monetising the metaverse. The market for industrial applications is nascent, but promises explosive growth as the metaverse technology itself becomes more widely deployed and available.

What is the industrial metaverse?

Ericsson’s metaverse is most often described as the ‘spatial internet’, a re-imagining of internet data and connectivity using 3D rendering, virtual spaces, and contextual information about surroundings. It can be a mirrored world, a cloud of augmented reality (AR) or mixed reality (MR) data or live map content.

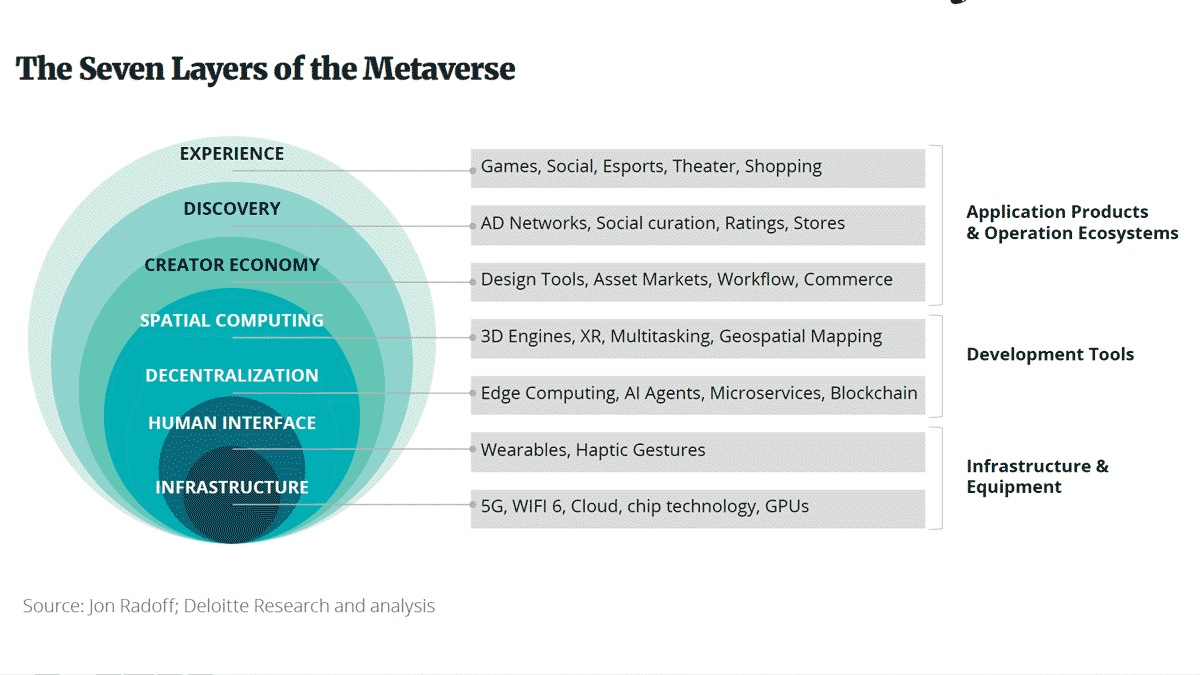

Like the metaverse itself, ‘industrial metaverse’ has become a general expression to describe similar technology implemented for industrial applications. The Industrial Metaverse is at the intersection of the Industrial Internet of Things (IoT), AR, MR and Virtual Reality (VR) for industrial use, creating ‘digital twins’ and richly blending real-world elements with contextualized elements and meaningful data to help decision makers stay better informed and keep business processes running at peak efficiency.

In fact, the roots of the industrial metaverse go back long before the Internet age. The foundations of the industrial metaverse were laid almost at the dawn of the computer age itself. The term ‘computer-aided design’ (CAD) was first coined in the 1950s. Around the same time, early pioneers were developing the first graphical display systems for computers. Early CAD implementations were developed for defence, but CAD eventually found its way into civilian use as computers found wider use in corporations. At that point, it was possible to conceptualise and create in digital space something that could be manufactured in physical space. Conceptually, the industrial metaverse is no different: it is a digital representation of reality. Just on a vastly different scale. Rather than just individual objects, the industrial metaverse is a complete digital universe with digital representations of the real.

Digital twins

Several companies find the industrial metaverse useful as a concept to demonstrate digital twins.

“A digital twin is a virtual model designed to accurately reflect a physical object. The object under study – for example, a wind turbine – is equipped with various sensors related to vital areas of functionality. These sensors produce data about different aspects of the physical object’s performance, such as energy output, temperature, weather conditions and more. This data is then transmitted to a processing system and applied to the digital copy,” explains IBM.

Digital twins differ from conventional computer simulations based on their size, according to IBM. “While a simulation typically studies a specific process, a digital twin can itself run any number of useful simulations to study multiple processes,” say company representatives.

Another differentiator, according to IBM, is the interactivity of the digital twins. “Digital twins are designed around a two-way flow of information that first occurs when object sensors provide relevant data to the system processor and then happens again when insights created by the processor are shared back with the original source object.”

Digital twins are increasingly viewed as one of the industrial metaverse key applications. These applications were first proposed in 2002 and later became a vital technology when the fourth industrial revolution accelerated automation and digitization across industries.

BMW, for instance, created a virtual twin of its production plant in Bavaria before building the physical facility. Boeing is using a digital twin development model to design its airplanes.

According to ABI Research, revenues for industrial digital twin and simulation and industrial extended reality will hit $22.73 billion by 2025 as organizations use Industry 4.0 tools such as artificial intelligence (AI), machine learning, edge computing, and extended reality to accelerate digital transformation.

Metaverse of engineers for the development of new generation nuclear technologies

One example is France. According to ‘France 2030’ plan, the country must prepare and develop tomorrow’s nuclear power. The stakes are high and the whole sector needs to be transformed to achieve the goals set for the coming years.

Nuclear power is still the largest part of the French energy mix, accounting for more than 67% of national energy production in 2020. According to Xavier Piechaczyk, president of RTE, the French electricity system operator, this situation is unlikely to change, as the country’s goal is to produce decarbonised energy without fossil oil and gas by 2050.

Development of disruptive technologies

Partly to meet this objective, the French government has launched the ‘France 2030’ investment plan, which aims to develop industrial competitiveness and future technologies with an allocation of €30 billion over 5 years. One of the objectives of this plan is to develop innovative technologies, in particular Small Modular Reactors (SMRs), which are reactors smaller in size and power than conventional reactors, originally used on ships or submarines.

Alongside SMRs, there is also a desire to launch the construction of six new EPR (European Pressurised Reactor or Evolutionary Power Reactor) nuclear reactors.

As the operator of the world’s leading nuclear fleet, EDF plans to maintain its position as a key nuclear industry player in the current favourable move to develop new projects. Many countries such as China are currently building nuclear power plants and others, such as the UK, are planning to build them. The Group therefore has a dual role: enhancing the existing fleet and devising the solutions of the future.

EDF has unparalleled experience in nuclear power plant design and construction. The group’s projects include building the new-generation Flamanville EPR unit in France.

Three significant transformational challenges for the nuclear industry

The transformational challenges for the nuclear sector are considerable and, to achieve this, the following three directions are most important.

- Global optimisation and co-design: New EPRs will need to be designed as mass-produced industrial products, integrating the performance of the industrial organisation, but also anticipating maintenance constraints and costs.

- Schedule control: because managing development times and production deadlines involving significant costs will be essential, given the political stakes and past experiences.

- Developing human skills: training operators and managing the qualification of teams. All planned nuclear projects necessarily involve considerable needs for qualified personnel. The sector must therefore respond to a very important training need in order to have in the short term qualified operational technical teams to carry out operations.

These three key directions need to be integrated with next-generation tools and digital transformation, and are essential for the nuclear sector to achieve state-of-the-art industrial standards.

By extension, it is indeed a profound development for the nuclear industry (and profession) currently taking place in France.

Using 3D models and VR solutions

New technological tools, relying heavily on the use of 3D models, need to be integrated into the heart of design, production, training and operational processes.

In addition, the fundamental challenge is to make 3D evolve into a common language; this implies that the industry needs to make a giant leap forward by having all stakeholders cooperate in setting new standards and operating methods.

SkyReal virtual reality products

SkyReal virtual reality products address many of these issues, and many use cases can be considered in the design, development and operation of complex systems such as EPR or SMR.

Virtual reality offers efficient possibilities to define installation and maintenance intervals, providing a view and thus an industrial 3D approach. Typically, it allows production engineers to define future operations by projecting directly into the operational scene, at 1:1 scale, of course, and define or verify a sequence.

Airbus reported, for example, that it managed to avoid more than 600 errors thanks to design reviews carried out in VR on the A350 assembly line project in St Nazaire before the line was delivered.

Other customers, such as ArianeGroup, who also develop products that are difficult to prototype at 1:1 scale, use SkyReal solutions as a validation tool for their assembly sequences.

As far as the nuclear sector is concerned, there are many opportunities to leverage the use of these solutions to improve the design of complex systems, such as EPR or SMR.