World’s First Carbon-neutral Cement Plant

The HeidelbergCement Group, which includes Swedish manufacturer Cementa, announced its intention to develop the world’s first carbon-neutral cement plant in Slite on Gotland. When the installation is commissioned in 2030 and begins capturing up to 1.8 million tonnes of carbon dioxide annually, of which an increasing proportion is biobased emissions, the plant that currently accounts for 3% of Sweden’s total emissions can even become a carbon sink.

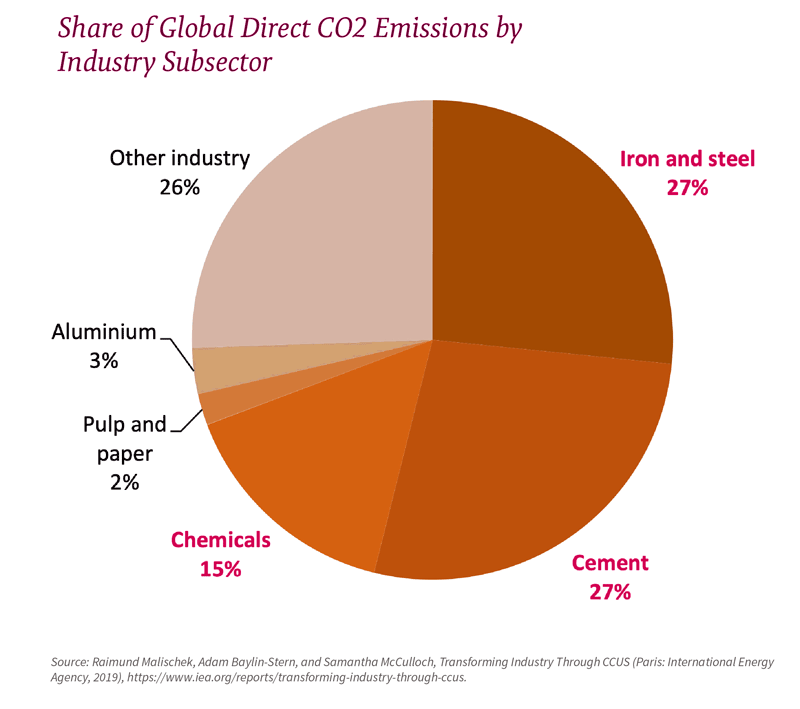

The cement industry accounts for about 8% of total global carbon dioxide emissions. To counteract global warming, finding solutions for the industry is a matter of urgency. CCS (carbon capture and storage) solutions, where carbon dioxide is captured and transported to a permanent storage site several kilometres down in bedrock, are currently the most mature technologies for controlling these emissions on a large scale.

The majority of carbon dioxide emissions from cement production arises when limestone is heated to high temperatures to develop its binding properties prior to concrete production. Three-fourths of the cement used for concrete production in Sweden is manufactured in Slite.

Establishment in Norway is a stimulus

In the winter, the Norwegian government confirmed its commitment to CCS. HeidelbergCement is now building the world’s first full-scale installation for carbon capture in Brevik, which will capture 400,000 tonnes annually, which corresponds to 50% of the plant’s emissions. At the same time, capacity is being built up to geologically store carbon dioxide from other industries as well. Planning for the plant on Gotland benefits significantly from the establishment of the facility at Norcem in Brevik, which is now well under way.

“Our strong goal of establishing a CCS installation in Slite means that Sweden has a chance to become a world leader in carbon-neutral cement production. Based on our positive experience of collaboration with the Norwegian government and their decision to invest in this technology, we have now chosen to ramp up our ambitions for a carbon capture installation in Sweden that is four times larger,” says Giv Brantenberg, General Manager of HeidelbergCement Northern Europe.

A feasibility study has been launched in order to define all critical steps towards establishing the world’s first carbon-neutral cement plant. It will look into issues related to technology choices, environmental impact, legal issues, financing, logistics and energy supply. As electricity demands are going to increase by up to five times compared to today, the venture will require significant upgrades of the power grid leading to and on Gotland. An effective regulatory framework for CCS and, not least, commercial driving forces are also needed in order to see this venture to fruition.

Authorisation processes and the construction period are estimated to take just under ten years.

The solution enables a carbon sink

The installation in Slite will be scaled to capture up to 1.8 million tonnes of carbon dioxide annually, which essentially means the entirety of the emissions. The use of biobased fuels is set to increase. As these are counted as carbon-neutral, net emissions will fall below zero and ‘negative emissions’ will be achieved.

“Our venture is a necessary piece of the puzzle in enabling Sweden to reach its climate targets by 2045 and for the goals of the UN Paris Agreement to be met. Since the cement industry accounts for a significant proportion of society’s carbon dioxide emissions, we have a great responsibility to contribute constructive solutions. Both the Swedish government’s declared willingness to invest in climate transition and the fact that there is increased pressure on the market for sustainable building materials empower us to be ambitious,” says Karin Comstedt Webb, Head of Sustainability at Cementa and HeidelbergCement Northern Europe.