Europe Closer to a Green Flight: Sustainable Fuels

In July, the European Parliament adopted its position on new draft EU rules to increase the uptake of sustainable fuels by EU planes and airports, to cut emissions from aviation and ensure Europe becomes climate neutral by 2050.

MEPs increased the European Commission’s original proposal for the minimum share of a sustainable aviation fuel that should be made available at EU airports. From 2025, this share should be 2%, increasing to 37% in 2040 and 85% by 2050, considering the potential of electricity and hydrogen in the overall fuel mix (EC proposed 32% for 2040 and 63% for 2050).

More types of sustainable fuel, including electricity and hydrogen

Parliament amended the proposed definition of sustainable aviation fuel, a term that covers synthetic fuels or certain biofuels, produced from agricultural or forestry residues, algae, bio-waste or used cooking oil.

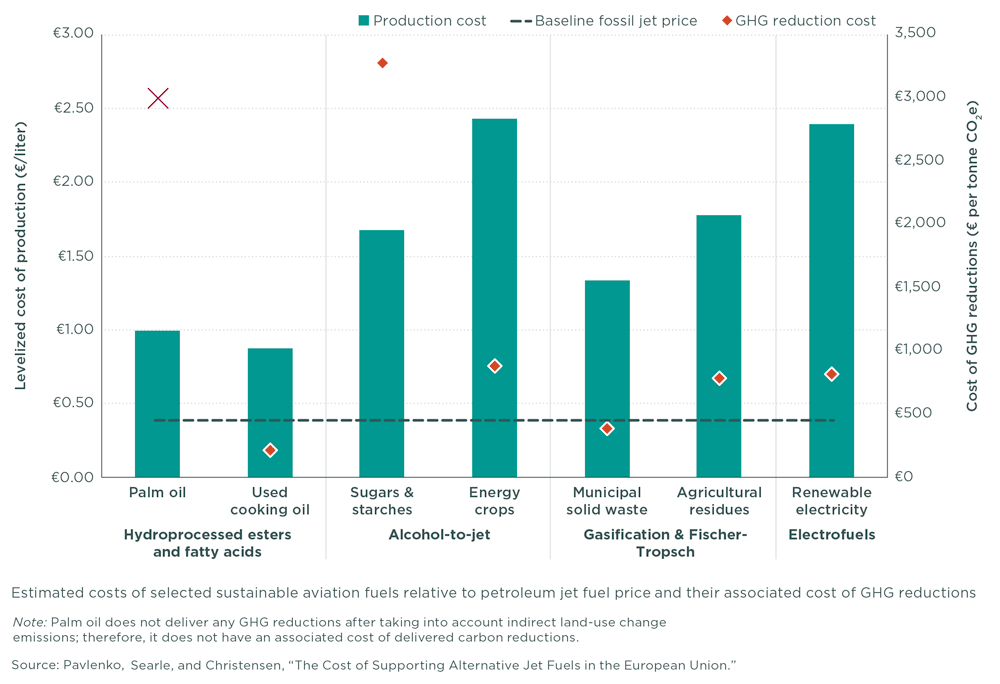

MEPs included under their definition recycled carbon fuels produced from waste processing gas, and exhaust gas deriving from production process in industrial installations. They also suggested some biofuels, produced from animal fats or distillates, could be included in the aviation fuel mix for a limited time (until 2034). However, MEPs excluded feed and food crop-based fuels, and those derived from palm oil, soy-derived materials, and soap stock, because they do not align with the proposed sustainability criteria.

MEPs also included renewable electricity and hydrogen as part of a sustainable fuel mix, as both are promising technologies that could progressively contribute to the decarbonization of air transport. According to the draft rules, EU airports should facilitate the access of aircraft operators to sustainable aviation fuels, including with infrastructure for hydrogen refuelling and electric recharging.

New fund and green labelling

Parliament proposed the creation of a Sustainable Aviation Fund from 2023 to 2050 to accelerate the decarbonization of the aviation sector and support investment in sustainable aviation fuels, innovative aircraft propulsion technologies, and research for new engines. The Fund would be supplemented by penalties generated by the enforcement of these rules.

To further promote the decarbonization of the aviation sector and to inform the public about greener aviation, MEPs tasked the European Commission with developing by 2024 an EU labelling system on the environmental performance of aircrafts, operators, and commercial flights.

Therefore, in Europe, aircrafts will soon have to be fuelled with alternative fuels, produced from waste or ‘green’ hydrogen. The target “near carbon-free aircraft”, but not before 2050, is ambitious and costly. And European companies do not intend to be the only ones subject to this constraint.

To decrease its emissions further significantly, while keeping a healthy economic growth, the aviation sector needs to reduce its current exclusive reliance on fossil jet fuel and accelerate its transition to innovative and sustainable types of fuels and technologies.

New zero-emission aircraft technologies such as electric- or hydrogen-powered aircraft are promising especially for short-haul flights but not expected to be mature soon enough to play a significant role in commercial aviation in the short or medium term.

Sustainable aviation fuels have the potential to deliver a major contribution to achieving the European Green Deal’s increased EU climate target for 2030 and the EU’s climate neutrality objective by 2050.

From 2 to 10 more expensive than conventional kerosene

If we take France as an example, the law requires any company leaving France to include 1% sustainable fuel in its kerosene. Before reaching 2% in 2025, then 3% in 2030. It is still a low level but could increase significantly in the future. The Fit for 55 plan of the EU aims at a target of 20% clean fuels in 2035 and 63% in 2050.

The impediment is that these alternative fuels currently cost from two to ten times more than conventional kerosene and risk to significantly increase the bill of airlines, as fuel represents almost a quarter of the expenses. Air France-KLM CEO Benjamin Smith has already done the math: incorporating 2% biofuel would cost between EUR 240 million and 280 million per year.

SAF, the miracle fuel?

Sustainable Aviation Fuel – SAF is an immediately available solution for achieving significant CO2 reductions in air transport. It can be dropped into existing storage and distribution infrastructure, airplanes, and engines without any modifications. Its progressive use worldwide should lead to a significant reduction in CO2 emissions from air transport because it produces 80% less CO2 on average across its entire life cycle.

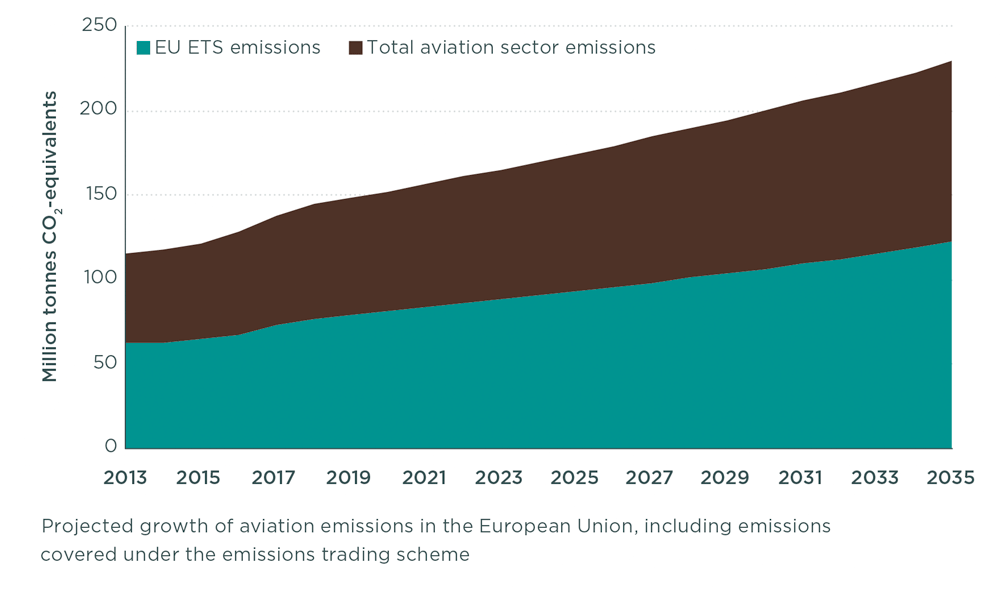

Derived from agricultural, food, forest waste or hydrogen mixed with CO2, SAF is yet presented as a new miracle fuel for reaching the carbon neutrality target in 2050. A challenge that will be difficult to fulfil for a sector that represents 2% to 3% of total carbon emissions and over 10% of those generated by transport. Due to traffic boom, before the Covid crisis, the rate increased by 28% between 2010 and 2018.

80% fewer emissions with a complete SAF

In this context, relying on new generation green fuels seems to be the quickest option. Sale of hydrogen-powered aircraft is not expected before 2035, and that of electric aircraft is not very suitable for long-distance flights due to the weight of the batteries. For experts at Archery Strategy Consulting, SAF should represent more than half of the sector’s efforts to reduce emissions by 2050.

“A full tank of biofuel emits up to 80% less CO2 than kerosene,” explains Vincent Etchebehere, director of sustainable development at Air France.

“Above all, SAF is compatible with current aircraft engines and can be blended with conventional fuel up to 50%. For now, the quota is set at 1%, it doesn’t sound like much, but it’s 30,000 tons less emissions, the equivalent of 550 Paris-New York flights,” argues the environment expert.

On May 18, 2021, Air France-KLM, Total, Groupe ADP, and Airbus announced they have joined forces to make the first long-haul flight fuelled by SAF produced in France.

The French company had a second test flight between Paris and Nice with 30% SAF in tanks, produced by TotalEnergies, in October the same year. This was a further realization by Air France and TotalEnergies towards supporting and developing the production of sustainable aviation fuel in France, as an essential condition for its widespread take-up in French airports.

The biofuel used for this flight was produced from waste and residues generated by the circular economy. It was made by TotalEnergies from used cooking oils at its biorefinery of La Mède (Bouches-du-Rhône) and its plant at Oudalle (Seine-Maritime). The French-produced SAF carries ISCC-EU certification (International Sustainability & Carbon Certification) awarded by an independent body which guarantees its sustainability.

Airbus announced, in March 2022, the take-off of the A380 MSN1 operating one engine on 100% SAF. This milestone marked the third Airbus aircraft, following the A350 and the A319neo, to test unblended sustainable aviation fuel.

“There are no major technical difficulties, just some checks to be done on fuel and engines, especially to see how the gaskets or pumps react,” details Steven Le Moing, new energy program manager at Airbus.

Two major obstacles for SAF

Later, two major obstacles will have to be overcome: lack of resources and high production cost. “SAF prices cannot fall without the establishment of a real industrial sector,” warns Amélie Lummaux, director of sustainable development at ADP. “However, transforming a power plant or building one takes time and effort”.

TotalEnergies invested no less than EUR 275 million to transform its La Mède site, near Marseille, into the largest biorefinery in France. But the company had to promise that it would stop biofuel production from palm oil, which harms the environment, from 2023.

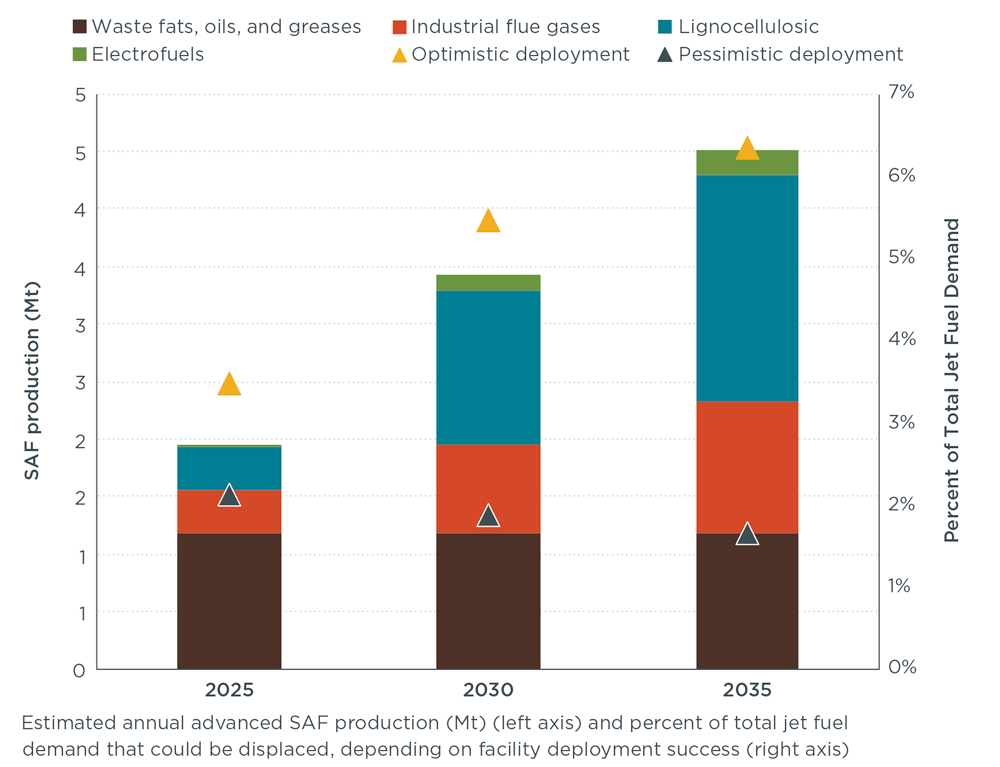

This is indeed the major concern of the defenders of the planet: SAF accounts for less than 0.1% of the 360 billion litres of fuels used in aviation in 2019, and to cover the future needs an increased attention to the types of fuels used and their origins will be necessary.

A step forward on the road to clean aircraft

The European Commission carried out tests with several aircraft that landed in Lyon, from several cities, including Bucharest. An aircraft, for example, arrived at Lyon from Porto, Portugal. A reduction of polluting emissions by 28% was noticed after fuelling the tank with sustainable fuel up to 30%.

The tests showed that the decrease in polluting emissions could go up to 70%, if the aircraft are new and have a reduced consumption, and air traffic control is optimized, so that the aircraft fly straight, without detours.

For Europe to be the first climate neutral continent, airlines would be gradually required to also use ‘green’ fuel. This type of fuel is currently produced in very small quantities globally, less than 0.2% of consumption, and the price is much higher than in the case of conventional fuel.

Emissions by 70% to 95% lower compared to petroleum-based kerosene

The share of SAF in fossil kerosene will be gradually increased, to make their incorporation acceptable, as they are scarce and expensive. Initially, the EC proposed the following levels: 2% of SAF in kerosene in 2025, 6% in 2030, 20% in 2035, 32% in 2040, 38% in 2045 and 63% in 2050.

This timetable is complemented by a second one, which sets a minimum share of synthetic SAF, the latter having the advantage of not exploiting any organic resource (plant or animal and which could be considered better used to produce, for example, biogas).

The measure will apply to 95% of passenger traffic departing from Europe

These obligations would apply to all civil aircraft operating commercial flights (but not military aircraft or aircraft performing rescue or humanitarian missions). And this in all European airports, except, if the Member States want this, the smallest ones (those who traffic represents less than two million passengers).

Despite this limitation, the measure will apply to 95% of passenger traffic departing from Europe/ Measures are planned to prevent aircraft transiting airports outside Europe to refuel there to avoid refuelling inside the EU.

In terms of fuel origin, the text explicitly excludes raw materials from agricultural production that can be used for animal or human consumption. Therefore, there is no question of adding beet, wheat or corn alcohol, or rapeseed oil, as is currently the case with car biofuels, not to mention palm and soybean oils, produced primarily in Indonesia and Malaysia, in South America, at the cost of great damage to the environment (deforestation, massive use of pesticides).

SAFs can be ‘biofuels’ derived from intentionally produced vegetable oils (which the European Union wants to avoid so that the aircraft is not a food competitor for humans and animals), waste oils, animal fats, processing of vegetable products (straw, bark etc.). These biofuels are currently three to four times more expensive than kerosene.

They can also be synthetic fuels, obtained by combining CO2 (from the air or from high-emitting factories) with hydrogen produced, preferably, by water electrolysis, using renewable or nuclear energy.

As for synthetic SAF, they must have a carbon footprint at least 70% lower than kerosene (to avoid the use of hydrogen from natural gas, currently the most common).

The rate of incorporation of SAF by aviation fuel suppliers can be calculated, from 2025 to 2034, not as a proportion for each litre of fuel sold, but as an overall average in total sales in the European Union. This seems to open the possibility for fuel suppliers to invest in SAF dedicated infrastructures only in certain large airports, especially those of the states that have already established higher SAF tariffs than those that are going to be imposed by Europe.

Therefore, France has 1%, since 2022. The Netherlands aims at 14% in 2030. But Norway (non-EU), Sweden and Denmark will impose 30% on the same date.

Air transport in Europe

SAFs account for only 0.05% of the fuel consumed in European airports, but it should be reminded that while the aircraft has become the hope of environmentalists, air transport accounts for just 2-3% of greenhouse gas emissions. In Europe, it is 3.7%, compared to almost 20% for road transport.

However, this low rate must be seen in relation to a significant upward trend. Even though aircraft are becoming more efficient (fuel savings of 30% to 50% per passenger transported over twenty years), traffic growth is progressing faster than aircraft performance. Civil aviation CO2 emissions increased from 674 to 1,027 million tons between 2000 and 2019. Therefore, there is an urgent need to counteract the aviation trend to pollute increasingly more.

Last year in January a KLM aircraft powered by synthetic fuel transported passengers from Amsterdam to Madrid. This was first flight in the world operated with synthetic kerosene. The KLM aircraft used regular fuel mixed with 500 litres of synthetic kerosene produced by Royal Dutch Shell with carbon dioxide, water, and renewable energy sources, along with regular fuel to power the aircraft.

“Sustainable fuel will potentially make the biggest contribution to emissions reductions in new airline fleets. The transition away from fossil fuel to durable alternatives is one of the biggest challenges facing the industry,” said KLM President and CEO Pieter Elbers.

KLM Royal Dutch Airlines is the first airline in the world to invest in biofuel for the aviation industry and aims for the next 10 years to purchase and use more than 75,000 tons of sustainable aviation fuel every year. KLM is the only airline in Europe that operates intercontinental flights partially fuelled with bio-kerosene. The raw material used for production consists of residual waste, such as cooking oil, mainly coming from factories in the area. The plant will operate based on sustainable hydrogen, produced by using water and wind energy.

SkyNRG, the world leader in the sustainable aviation fuel market, is developing the first factory in Europe specialized in the production of biofuel for the aeronautical industry. The factory is built in Delfzijl, the Netherlands. The construction of this factory is in line with KLM’s sustainability goals and represents an important step towards the implementation of the industry’s ‘Smart & Sustainable’ action plan, developed by 20 transport organizations and research centres.

The project has received EUR 20 million in grant funding from the EU’s Horizon 2020 research and innovation program. The facility is expected to be fully operational in 2024. When completed, the plant is set to produce 100,000 tons of SAF annually from waste and residue streams such as used cooking oil. The project is being supported by Shell, which has an option to purchase SAF from the facility, with KLM committed to purchasing 75,000 tons annually for 10 years.

The best short-term solution

In addition to the energy efficiency of aircraft (engines, aerodynamics), which could ensure 42% of energy savings expected until 2050, there is a slightly better management of flights and ground operations (8%), and in particular, for 50%, the use of fuels that do not emit CO2.

In this case, the widespread use of pure hydrogen as fuel burned in a reactor or as a reactant in a fuel cell that powers electric motors seems remote.

As for aircraft with electric batteries, this should be limited, for reasons of weight, to machines that fly only a few hundred kilometres with a few dozen passengers. Indeed, the development of ‘green’ fuels adapted to the current reactors or turbo-propellers is the major solution for a quick large-scale decarbonization of aviation.

Unfortunately, SAF are almost non-existent in global civil aviation, which consumes between 250 and 300 million tons of fuel per year. And the International Energy Agency (IEA) estimates in a recent report that the global SAF production capacities existing in 2020 could provide only half of what would be necessary for aircraft to operate with only 2% of SAF in 2050.

However, aviation fuel suppliers are gaining momentum in terms of SAF. According to analysts, the market, which currently barely exceeds USD 200 million, could reach USD 15.7 billion in 2030, with much better prospects for 2050.

While the movement is very active in the United States, with strong public financial incentives, in Europe Neste, controlled by the Finnish state, seems to be among the most advanced.

Neste MY Sustainable Aviation Fuel™ (SAF) is a next generation aviation fuel, made from 100% renewable waste and residue raw materials, like used cooking oil. Over the lifecycle, SAF reduces greenhouse gas (GHG) emissions by up to 80% compared to fossil jet fuel. SAF can be used as a direct replacement (drop-in) for fossil jet fuel as it is chemically similar. It is fully compatible with existing jet engines and fuelling infrastructure, requiring zero additional investment into them.

Replacing crude oil with renewable raw materials in the production of fuels helps combat climate change through preventing significant amounts of fossil-based greenhouse gas emissions from entering the atmosphere.

Neste currently has an annual production capacity of 100,000 tons (approximately 34 million gallons) annually. By the end of 2023, Neste will have the capacity to produce some 1.5 million tons (515 million gallons) of SAF annually.

Neste will increase its total production capacity of renewable products to 5.5 million tons by the end of 2023 and will be the only global provider of renewable products with a production footprint in North America, Asia, and Europe.

Sustainable Aviation Fuels in Romania

In Romania, OMV Petrom will produce sustainable aviation fuel at the Petrobrazi refinery by co-processing locally produced rapeseed oil.

Petrobrazi refinery becomes the first ISCC certified refinery in the country to produce SAF and HVO by co-processing raw materials of a biological nature. The SAF volumes produced at the Petrobrazi refinery for commercial flights will help reduce the CO2 emissions by about 70% compared to the conventional fuel.

At the same time, the company aims to increase the production capacities in the future, to produce advanced sustainable fuels based on various waste feedstocks (i.e., used cooking oil).

In June this year Air France – KLM Romania and Trust Motors have signed the first contract to produce sustainable aviation fuel.

By investing in the airline’s dedicated Corporate – SAF (Sustainable Aviation Fuel) program, Trust Motors wants to contribute to the green transition of transportation in the aviation industry.

Through the SAF program, corporate customers Air France and KLM can estimate their CO2 emissions associated with their trip, and then determine the annual participation they want to make in this program. Air France-KLM invests all its contributions in the supply and use of sustainable aviation fuel.

In October 2021, Clariant, a focused, sustainable, and innovative specialty chemical company, announced the official completion of its sunliquid® cellulosic ethanol plant in Podari, Romania.

In June 2022, Clariant announced that it has produced the first commercial cellulosic ethanol at its sunliquid® production plant in Podari. The entire offtake is contracted with a multi-year agreement to Shell, a leading global energy company.

Over the last months, the plant underwent a thorough commissioning process resulting in the successful start of production. Approximately 50,000 tons of second-generation biofuels will be derived from 250,000 tons of locally sourced agricultural residues. The cellulosic ethanol produced at this plant can be applied as a drop-in solution for fuel blending, but also offers further downstream application opportunities for sustainable aviation fuel (SAF) and bio-based chemicals.