Technip Energies’ First Hummingbird® Catalyst Supply for LanzaJet Biorefinery

Technip Energies has signed its first catalyst supply agreement with LanzaJet, a sustainable aviation fuel (SAF) producer, for its proprietary Hummingbird® ethanol-to-ethylene catalyst. LanzaJet’s SAF delivers more than 70% reduction in greenhouse gas emissions on a lifecycle basis, compared to conventional fossil jet fuel. The catalyst will be used in LanzaJet’s first commercial demonstration scale integrated biorefinery at its Freedom Pines Fuels site in Soperton, Georgia, USA. Technip Energies was awarded its first commercial License for the Hummingbird® Ethanol-to-Ethylene technology by LanzaTech in 2019, founder and investor in LanzaJet.

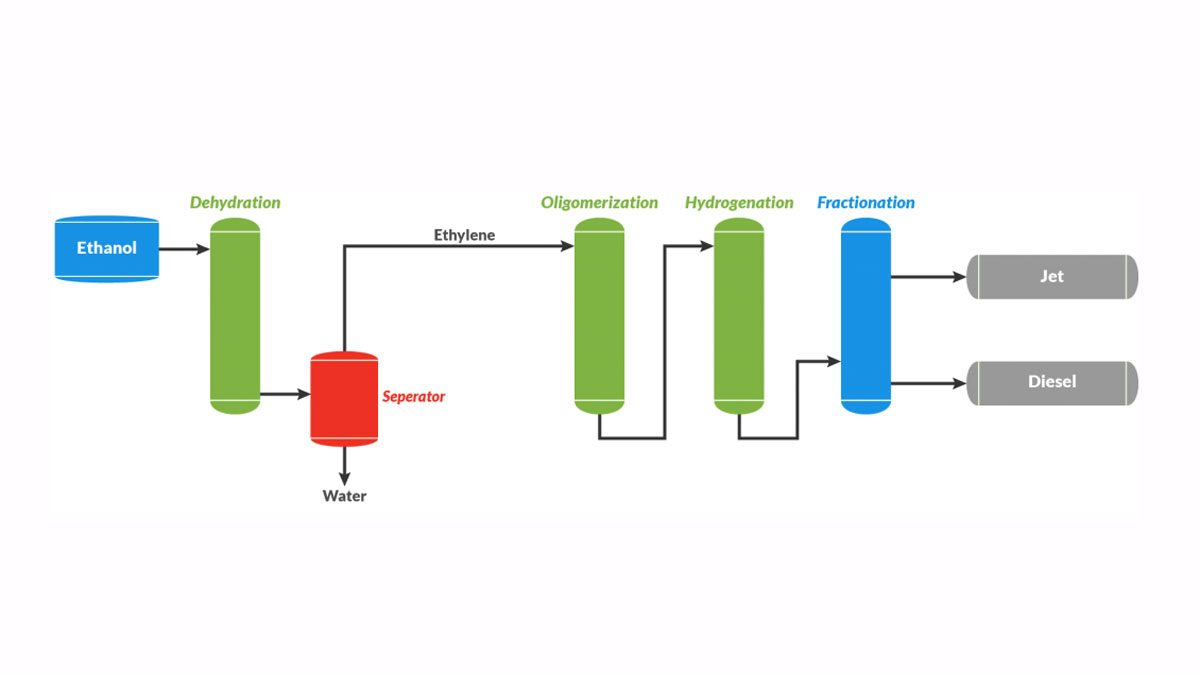

Hummingbird® is a second generation, low-cost process for dehydrating ethanol to produce ethylene. It gives ethylene derivative producers an option to produce ‘niche’ renewable products from sustainable bioethanol sources. A key feature of Hummingbird® is its proprietary catalyst operating at a lower temperature, higher pressure and producing a polymer grade ethylene with over 99 percent selectivity.

“We are very excited about licensing this technology and the first sale of the proprietary catalyst for LanzaJet’s biorefinery which was brought to realization through our R&D technology licensing teams. Hummingbird® is just one of the many sustainable chemistry technologies that we have to offer as a part of our energy transition business,” Stan Knez, Senior Vice President of Technip Energies Process Technology, stated.

“Decarbonizing the aviation sector is an imperative and demand for sustainable aviation fuel is growing significantly. The use of the Hummingbird® ethanol-to-ethylene catalyst will allow LanzaJet to scale and grow strategically to meet the aviation industry’s need for sustainable fuel. In fact, it will help us double production and usage of SAF in the United States, starting in 2022, and help the aviation industry reduce emissions and its reliance on fossil fuels used to power its planes,” Jimmy Samartzis, LanzaJet CEO, added.

Hummingbird® technology – A process to convert ethanol to ethylene through dehydration

Hummingbird is a second generation, low-cost process for dehydrating ethanol to ethylene. The technology uses a proprietary heteropolyacid (HPA) supported catalyst, operating at a lower temperature, higher pressure, and higher selectivity than first generation processes.

Low capital intensity process

Hummingbird is ideal for modest scale ethylene capacity additions or when production is remote from world-scale ethylene infrastructure.

Producing niche derivatives

Hummingbird gives ethylene derivative producers an option to produce ‘niche’ renewable derivatives from sustainable bioethanol sources.

Diversifying ethanol production

Hummingbird can be an important step into alternative chemical pathways or a building block for a bio-refinery.

Hummingbird process advantages

Bioethanol feedstock flexibility

As commercial bioethanol can contain a variety of trace components which may affect ethanol dehydration process performance, Hummingbird technology includes a “toolkit” for the clean-up of bioethanol feedstocks. This was developed from the analyses of over 50 bioethanols from various sources, providing enhanced feedstock flexibility.

Ultra-selective reaction

Using an HPA catalyst, Hummingbird produces polymer grade ethylene with over 99% selectivity.

Simplified product separation

Hummingbird operating conditions reduce capital and operating costs and is readily integrated into existing petrochemical utility systems. Mild process temperatures do not require dilution water to prevent catalyst coking, ultra-selectivity removes the need for a C2 Splitter or CO/CO2 removal in product separation, and product compression power is reduced.

Proven pilot operation

A fully recycling facility with purification columns, similar to a full commercial plant, has proven the ultra-selective operation of Hummingbird technology with over 24,000 hours of operation on commercial bioethanol feedstocks.

Successive commissioning, development, and demonstration operating phases have developed a thorough understanding of the process operation.

Operating at multi-kg per hour ethylene production rate, and incorporating bioethanol clean-up facilities, the pilot plant has produced bioethylene product to specification.

Proprietary HPA catalyst development

Operating guidelines, developed from knowledge of the pilot plant operation, ensure that catalyst operation is maintained during start-up, shutdown, and steady state operation with a catalyst life in excess of two years.

Technip Energies’ proprietary HPA catalyst formulation has been manufactured at commercial scale. Pilot Plant operations using the commercially produced catalyst have performed in accordance with design selectivity and catalyst life expectations.

Polymer grade bioethylene

The ethylene produced from Hummingbird technology is indistinguishable from that produced from Technip Energies’ conventional ethylene technologies; although may be labelled as bioethylene if produced from bioethanol.

Successful downstream polymerization tests have been performed on pilot plant products using Ziegler Natta and Metallocene catalysts.

Hummingbird process stoichiometry and process economics

As over 90% of the variable cost of ethylene production from ethanol dehydration is the cost of the ethanol feed, selectivity is key to a commercially competitive process.

Hummingbird shows a clear advantage over first generation processes, resulting in reduced ethanol consumption.

The combined benefits of lower ethanol feed consumption, greater integration with existing plant utilities, and simplification of the product separation, gives real world benefits in terms of reduced capital and operational expenditures compared to first generation processes.