Toyota Motor Europe Envisages 100% CO2 Reduction by 2035

Starting Production of 2nd Generation Fuel Cell Modules

Toyota Motor Europe (TME) is targeting a carbon-neutral society. And, to achieve this goal, the company is developing multiple electrified technologies, including hydrogen which it views as one of the key building blocks in CO2 reduction. Toyota’s hydrogen commitment goes well beyond passenger cars, and it is making its fuel cell technology available in easy-to-use modules for partner applications.

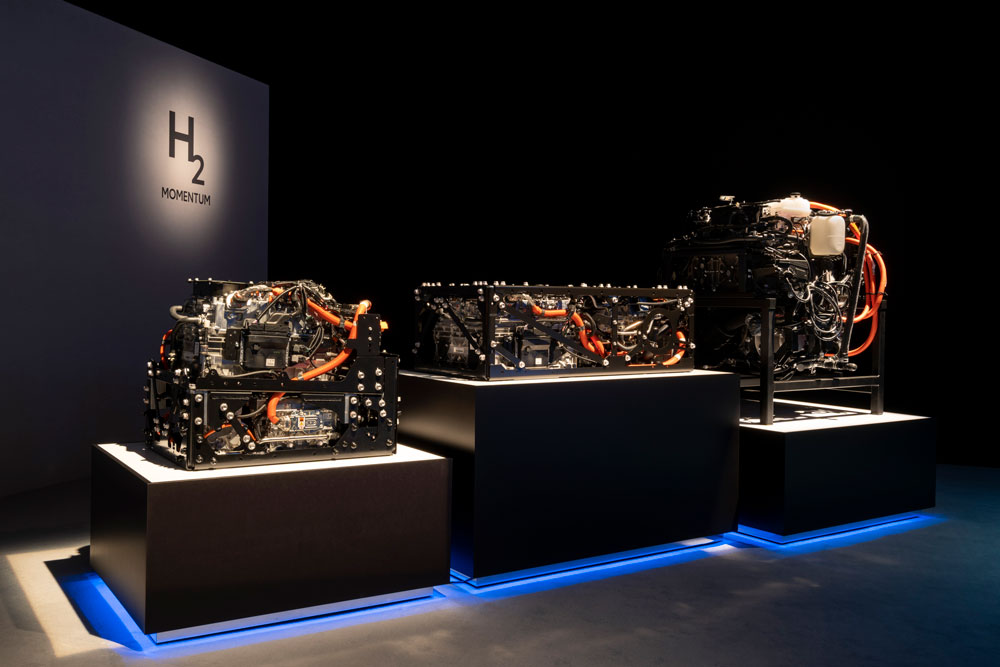

2nd generation fuel cell modules

To help facilitate the expansion of its hydrogen technology from cars to diverse uses, Toyota Mirai’s fuel cell system has been re-packaged into compact fuel cell modules. From January 2022, Toyota will start production of the 2nd generation modules, based on its advanced 2nd generation fuel cell system. The new system, which is packaged into more compact, lighter modules also provides more power density. The modules are available in two shapes, a cube, and a flat, rectangular shape to allow more flexibility and easier adaptation for a variety of applications.

European production

Toyota began fuel cell development way back in 1992 and the company has continued to refine its hydrogen technology. The new second generation fuel cell modules will also be assembled by their manufacturing team in Europe, at Toyota Motor Europe’s (TME) Research and Development facility, in Zaventem, Brussels. Starting in January 2022, the new facility houses a pilot assembly line combining advanced technology content with high-quality assembly.

Toyota took the decision to assemble their second-generation fuel cell modules in Europe, as it sees demand grow significantly across the region. In collaboration with entrepreneurs interested to use Toyota’s technology in their applications, TME’s Fuel Cell Business Unit will offer the necessary engineering support for integration. This proximity to its partners and the ability to closely monitor emerging business opportunities, will allow the company to scale up supply quickly.

Hydrogen Clusters

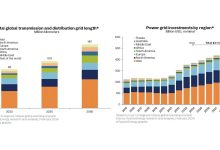

The expansion of a European Hydrogen economy will be a key element in achieving the Green Deal’s objective of net-zero global warming emissions by 2050. The EU has stated that to meet this challenge, industry will need ‘climate and resource frontrunners’ to develop the first commercial applications of breakthrough technologies in key industrial sectors by 2030. The emergence of hydrogen clusters in Europe sees different sectors uniting and bringing their skills, technologies, and applications together – such as truck, bus, taxi fleets and H2 infrastructure, to create viable business opportunities, allowing them to flourish and become the nucleus of larger-scale activities.

As it implements hydrogen technology solutions to a wide range of applications, Toyota supports the creation of a hydrogen environment, a ‘living oasis’, where supply and demand meet to further grow.

Toyota Motor Europe outlines its path to 100% CO2 reduction by 2035

Toyota executives explained the company’s strategy to reach carbon neutrality as quickly as possible, whilst minimizing carbon emissions during the journey to neutrality.

The goal of minimizing carbon emissions will be achieved by accelerating electrification and offering a diverse range of CO2 efficient powertrain solutions to all its customers.

In the coming years, Toyota will roll out an increasing number of practical and affordable zero emissions vehicles (ZEVs) with the bZ4X being the latest model to be launched. By 2030, the ZEV sales mix is anticipated to be a minimum of 50% in Western Europe, with the capacity and capability to further increase should customer demand go even higher.

“Moving beyond 2030, we expect to see further ZEV demand acceleration and Toyota will be ready to achieve 100% CO2 reduction in all new vehicles by 2035 in Western Europe, assuming that sufficient electric charging and hydrogen refueling infrastructures are in place by then, together with the renewable energy capacity increases that will be required,” Matt Harrison, President & CEO of Toyota Motor Europe, said.

Gill Pratt, TMC Chief Scientist & TRI CEO, further explained that the path to carbon neutrality is most efficiently based on diversity of powertrain solution due to the wide diversity of markets around the world, stemming from three key factors: diverse nature of energy sources across regions, the different transportation needs of people and thirdly, the imperative to maximize the Carbon Return on Investment to ensure that use of scarce battery raw materials is optimized: “Whilst Toyota is committed to making millions of Battery Electric Vehicles available to customers, the way to reduce the most net carbon emissions globally is to use every item in our toolbox, including Hybrid Electric, Plug-in Hybrid Electric, Battery Electric and Fuel Cell Electric Vehicles, with the proportions of each optimized to make best use of the infrastructure constraints and customer circumstances of every region, and the limited supply and improving performance of batteries.”

More details of Toyota’s battery strategy were shared by Gerald Killmann, Vice President of TME R&D, following the recent global announcement of its €11.5 billion battery investment strategy.

Commercial production has started on the world’s first bi-polar NiMh battery which, as well as using fewer precious minerals, is lower in cost with double the output density of a regular NiMh battery.

By applying similar techniques to Li-Ion batteries, combined with further efficiencies in vehicle energy consumption, Toyota expects to see a 50% reduction in battery cost per vehicle, without deteriorating range, in the second half of the 2020s: thereby making battery electric vehicles more affordable and accessible.

On the keenly anticipated introduction of solid-state batteries, Gerald Killmann confirmed that, following prototype testing last year, they will likely be first introduced in hybrid electric vehicles before wider deployment including battery electric vehicles with the aims of delivering higher output, longer range and shorter charging times.

Expanded electrified portfolio driving further growth

Toyota Motor Europe expects to deliver 1.07m vehicles in 2021, for an estimated 6.3% market share – a new record and an increase of 80k units compared to 2020. In 2022, TME is planning to sell around 1.3m vehicles for a 6.5% market share – another new record.

Underpinning the anticipated 230k sales growth between 2021 and 2022 is strong product power, including wide availability of TNGA platforms and a highest-ever electrification mix of around 70% currently.

It is also supported by strong new model introductions including the new bZ4X, the Aygo X, the GR86 and the Corolla Cross.

Toyota hydrogen technology is already integrated into passenger cars, buses, trucks, trains, marine and stationary applications. Toyota Motor Europe will begin production in Belgium of the Toyota Generation 2 Fuel Cell module from January 2022.

Hydrogen-powered ROV concept

Lexus has revealed a new ROV (Recreational Off-highway Vehicle) Concept, a unique hydrogen-powered vehicle offering near zero-emissions driving combined with extreme off-road capability. It reflects a commitment by Lexus to ensure exhilarating driving can co-exist with a carbon-free society centred on responsible mobility.

For the Lexus ROV Concept, the design team developed a vehicle that would look good in all kinds of natural environments. The car bears all the true hallmarks of an off-road vehicle with its exposed suspension, protective cage, and chunky off-road tyres for driving along muddy tracks. Dimensions are: 3,120 mm (length), 1,725 mm (width), 1,800 mm (height).

With the Lexus’ ‘human centred’ philosophy as their starting point, the design team wanted to create the kind of vehicle people would expect from a luxury carmaker yet without losing the rugged performance of an ROV. They designed a body that could protect passengers, incorporate the iconic Lexus signature grille, and preserve enough travel for the front suspension. In addition, the front fenders were conceived to offer protection against any stray rocks and mud.

The suspension cover, connected to the rear hydrogen fuel tank, protects functional parts as well as conveying the sense of durability inherited from Lexus SUVs. The dark bronze paint is carefully crafted along with a lightweight body and suspension designed for both comfort and fun off-road driving. Lexus ‘L’-motif front and rear lights and the rear LEXUS badge express the latest Lexus design language.

Inside, based on the Tazuna concept, it has a simple meter that instantly reads the information the driver needs while the driver concentrates on driving.

The new concept showcases outstanding build quality with the luxury feel of Lexus craftsmanship in both the interior and exterior, as never been seen before in a ROV. Luxury details include a leather steering wheel and a sculpted shift knob and seats which feature suspension elements that smooth bumps out of the ride. The seats are upholstered in hard-wearing synthetic leather. For demanding off-road driving, the first Lexus hydrogen ICE will meet all the carmaker’s stringent requirements for QDR (Quietness, Durability, Reliability).

Clean yet exciting hydrogen power

While tackling its carbon neutrality goals, Lexus is passionate about the enjoyment of driving cars. This ROV Concept embodies the exciting sound of an ICE and the responsive rise in torque that comes from the fast combustion speed of hydrogen, which Lexus believe is highly compatible with the ROV.

This hydrogen powered ROV concept is the result of Lexus’ desire to preserve true off-road pleasure in tomorrow’s low carbon society. To power this off-road fun, the 1.0-litre hydrogen engine works just like a petrol engine, but with a high-pressure tank for compressed hydrogen which is delivered precisely by a direct hydrogen injector. Importantly, Lexus’ new hydrogen engine produces close to zero emissions, with a negligible amount of engine oil burned during driving.

Developed with its own ‘Lexus Driving Signature’

With a lightweight body composed of a strong pipe frame and suspension that boasts a large amount of travel, the driver will enjoy the car’s natural movements, the distinctive ‘Lexus Driving Signature’ and the possibility to go anywhere they desire. Designed for dynamic and comfortable driving, the agile design and the responsiveness of the hydrogen engine make the Lexus ROV a fun vehicle to drive with exceptional off-road capability.

“The Lexus ROV is our response to the growing passion for the outdoors and adventurous spirit of luxury consumers. As a concept, it fuses our desire to also develop lifestyle-oriented products with our ongoing research into new technologies that contribute to carbon neutrality. As well as delivering a concept that is thrilling to drive, it has near zero emissions thanks to its hydrogen powered engine,” Spiros Fotinos, Head of Lexus Europe, commented.