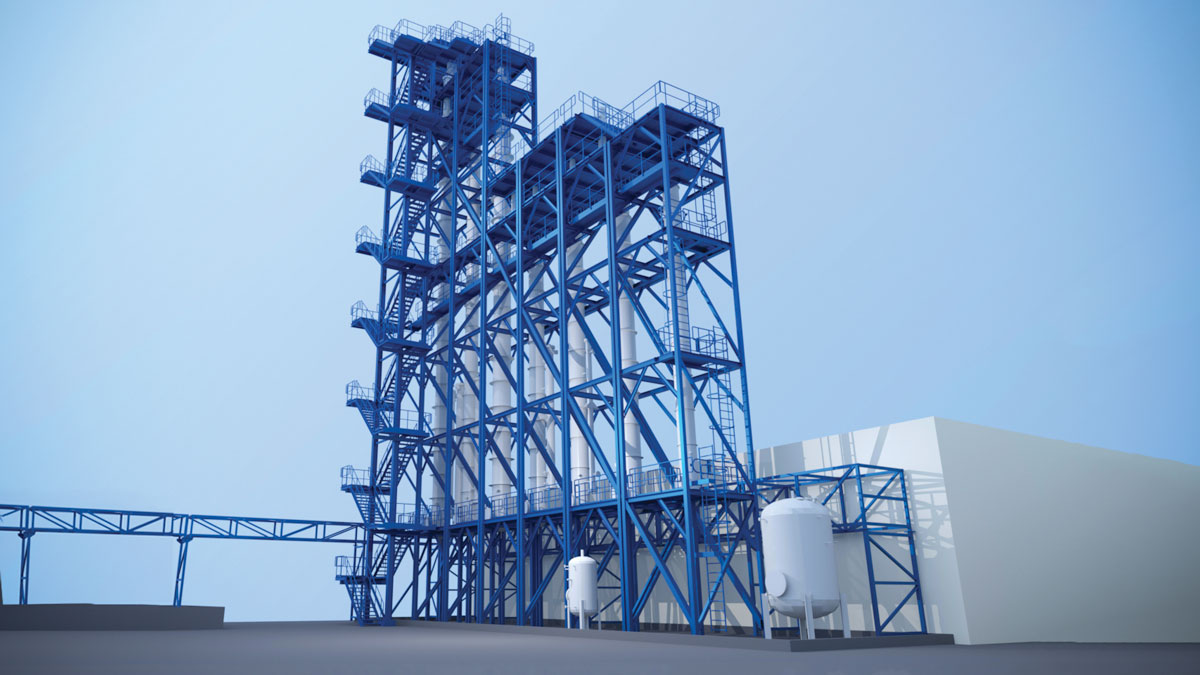

World’s Largest Biomethanol Purification Plant

ANDRITZ Group, Austria-based international technology group active in the supplies of plants, has announced a new order from Veolia Services Suomi, a Veolia Group company, for the supply of a biomethanol purification plant to be used in Metsä Fibre’s bioproduct mill in Äänekoski, Finland. The biomethanol purification plant will be used to refine the crude sulphate methanol generated in pulp production to obtain commercial grade biomethanol.

The plant, which will be integrated into Metsä Fibre’s bioproduct mill in Äänekoski, Finland, refines the crude sulphate methanol generated in pulp production to obtain commercial grade biomethanol.

The biomethanol purification plant will be designed to produce 12,000 tons of biomethanol per year, making it the world’s largest of its kind when it goes into operation. Start-up of the plant is scheduled for 2024. The ANDRITZ delivery to Veolia includes proprietary process design and full EPC delivery, excluding civil works.

The biomethanol purification process is part of the ANDRITZ CircleToZero initiative aimed at achieving zero emissions and zero waste from pulp mills and is a patented extraction process yielding commercial grade biomethanol. The CircleToZero initiative also offers other next-generation solutions for the chemical recovery cycle of pulp mills, with the target of utilizing pulp mill side streams to the maximum extent possible.

The biomethanol purification plant is a key component in the process for producing sustainable biomethanol from renewable raw material. The fossil-free biomethanol can be used for applications in the pulp mill itself or as a substitute for fossil-based methanol in the transport sector (biodiesel) and as a chemical base substance.

With the world’s largest fossil-free biomethanol plant of this kind, Veolia and ANDRITZ’s unique technology are strongly supporting the further development of Metsä Fibre’s unique bioproduct mill approach, which combines efficient raw material use with environmental and energy efficiency. In accordance with the principles of the circular economy, production side streams – in this case, crude sulphate methanol – are utilized and upgraded to obtain products with the highest possible added value.

“Veolia highly values how this industrial partnership has been developed based on a common vision to use natural resources more efficiently and process existing side streams to create new, sustainable bioproducts that can replace fossil-based fuels and materials,” Jacob Illeris, Business Development Director, Veolia Nordic, said.

About ANDRITZ Group

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services, and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

About ANDRITZ Pulp & Paper

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.