Europe leading the world in copper recycling

The metal of the energy transition, powering renewable energy systems and green technologies

Copper is the world’s most reusable resource and for nearly 5,000 it was the only metal known to man. Currently copper is one of the most used and reused of the present-day metals.

There are some interesting facts about the copper to keep in mind.

- Copper has an infinite recyclable life. Copper, by itself or in any of its alloys, such as brass or bronze, is used over and over again.

- Copper was first used by humans more than 10,000 years ago. A copper pendant discovered in what is now northern Iraq has been dated about 8700 B.C.

- According to Copper Development Association, known worldwide copper resources are estimated at nearly 5.8 trillion pounds of which only about 0.7 trillion pounds (12%) have been mined throughout history… and nearly all of that is still in circulation, because copper’s recycling rate is higher than that of any other engineering metal.

- Each year in the USA, nearly as much copper is recovered from recycled material as is derived from newly mined ore… and when you exclude wire production, most of which uses newly refined copper, the amount of copper used by copper and brass mills, ingot makers, foundries, powder plants and other industries shows that nearly three-fourths (72%) comes from recycled copper scrap.

- More than half of this scrap is ‘new’ scrap, such as chips and turnings from screw machine production… the remainder is ‘old’ scrap, such as discarded electric cable, junked automobile radiators or even ancient Egyptian plumbing.

- Copper’s recycling value is so great that premium-grade scrap normally has at least 95% of the value of the primary metal from newly mined ore.

- The ability to reuse copper extracted from recycled product is a tribute to an industry that’s environmentally conscious regarding its use of natural resources on behalf of consumers.

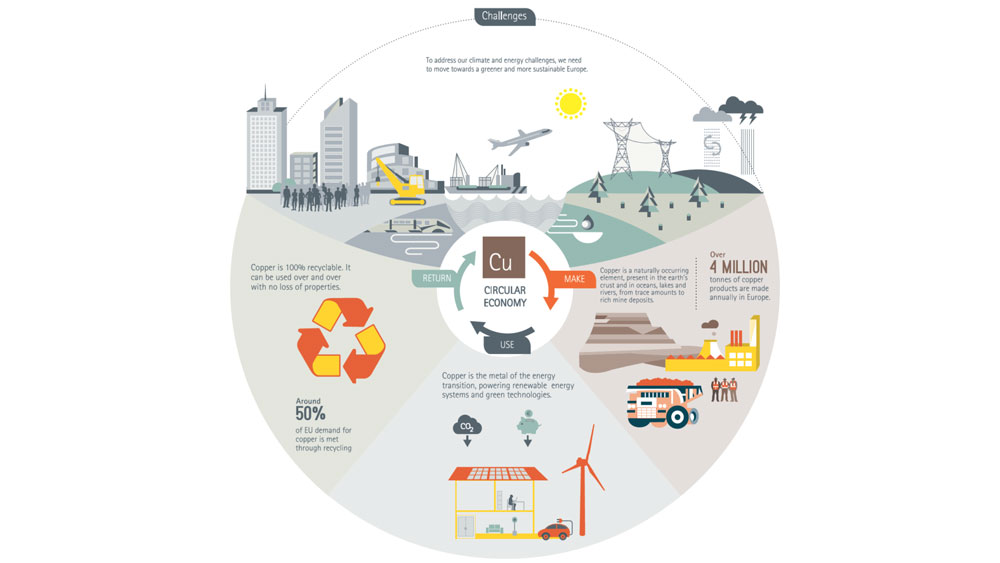

Copper and the circular economy

Once mined, copper can be recycled over and over with no loss of properties. As such, it is a sustainable material that is pivotal to building the circular economy. Responsible mining and successful recycling help make copper sustainable and resource-efficient.

Copper ore used in the EU is mainly imported from Chile, Peru, Australia and the USA, though there is also some production in Europe, including Finland, Poland, Spain and Sweden.

Copper mining provides many valuable by-products that can be used in advanced material applications, including cobalt, molybdenum, rhenium, selenium, tellurium and rare earth elements, as well as silver, tungsten, gold, lead and zinc.

Copper is the metal of the energy transition, powering renewable energy systems and green technologies.

Renewable energy systems use up to 12 times more copper than conventional power systems. Copper also typically improves energy efficiency. One tonne of copper used in rotating machines—such as an electric motor or a wind turbine—saves 7,500 tonnes of CO2 emissions over its lifetime.

Copper consumption is predicted to rise more than 40% by 2035. Partly driven by green technologies—like solar and wind power, and electric vehicles—additional demand will be met through mining and recycling.

Copper can be recycled repeatedly without any loss of performance, and recycling requires up to 85% less energy than primary production. Globally, this saves 40 million tonnes of CO2 annually.

Europe already leads the world when it comes to copper recycling, with nearly 50% of its copper demand currently met by recycled material. The industry is now working to go even further.

Copper’s life cycle

The copper industry is at the forefront of industries committed to reducing the environmental impact of its operations. Today, one third of the energy consumption of modern European copper manufacturing is used to operate environmental protection measures.

In response to requests from end-users and regulators—along with the industry’s own sustainable development goals, research and analysis—the copper industry has conducted detailed copper life cycle assessments (LCA) on the production of copper metal, and the leading semi-finished copper products (sheet, tube and wire). Hence, a Life Cycle study has been performed through cooperation between the Deutsches Kupferinstitut (DKI), IME Aachen, PE Europe, the European Copper Institute and the global copper industry.

A complete copper life cycle analysis starts with the raw materials. In the case of metals, these are provided by ore extracted through mining and by secondary sources (end of life scrap and production residues). It continues through all production steps of the metal itself, to those used for semi-products, followed by those for finished products. In this compilation of input and output data, the impacts from the production of process chemicals, power generation, etc. are also included.

The inventory data are based on industry inputs covering the EU-25 production of refining/smelting, electrorefining and semi-production for the reference year 2005. Mining operations and metal production activities, outside of Europe, have been modelled on a global scale and integrated into the European production dataset based on trade statistics. Data will be updated on regular basis.

Globally, about 90% of all copper is produced from sulphidic ores, with the other 10% from oxidic ores. This results in a specific advantage for copper whereby, during the smelting process, there is no requirement for process fuel or for carbon as a reduction agent. Instead, smelting and fire refining is fuelled by the energy provided by the sulphur within the ore. There is even an excess of energy which can be used to either melt secondary material (scrap) within the same process, or to generate heat or power for other uses.

The next step is electro-refining which removes remaining impurities in the raw metal, either from the ore or from secondary sources, to achieve the desired copper purity of 99.99+ %. This is independent of the number of use cycles that the metal has already gone through. Downstream metal processing steps include the fabrication of semi-finished products, such as tube, strip, sheet, rod, wire, bars and sections.

Most copper ores contain valuable by-products such as molybdenum, gold, silver and nickel. The molybdenum can be separated at the mine during the production of the intermediate known as concentrate. Gold, silver and nickel follow the process and are recovered during the electrolytic refining step. Sulphuric acid and steam are also valuable by-products of the process.

The impacts from mining and refining also need to be shared across these valuable by-products. While there are different, recognised methodologies for doing so, the copper industry has chosen the one that allocates burdens as a function of society value, using the transparent market price of these commodities.

While the study is currently focused on mining through to the manufacture of copper products, the methodologies and results take into account the fact that secondary materials (scrap) are an important source of raw materials for the production of copper in Europe.

When carrying out comparative life cycle assessment research, it is important that the users of these results recognise that, unlike copper, not all materials are 100% recyclable without any loss in performance. Cradle to grave comparisons are made including the use phase, along with the appropriate mix of either recycling, or disposal at the end of life.

In the case of ‘end of life’ copper, which has a high intrinsic economic value, users should make use of a full cradle-to-cradle approach.