Introducing Fossil-free Steel into Vehicle Production

The Swedish steel manufacturer SSAB and Mercedes-Benz are launching a partnership to introduce fossil-free steel into vehicle production as early as possible. The first prototype parts for body shells made of SSAB’s fossil-free steel are already being planned for next year.

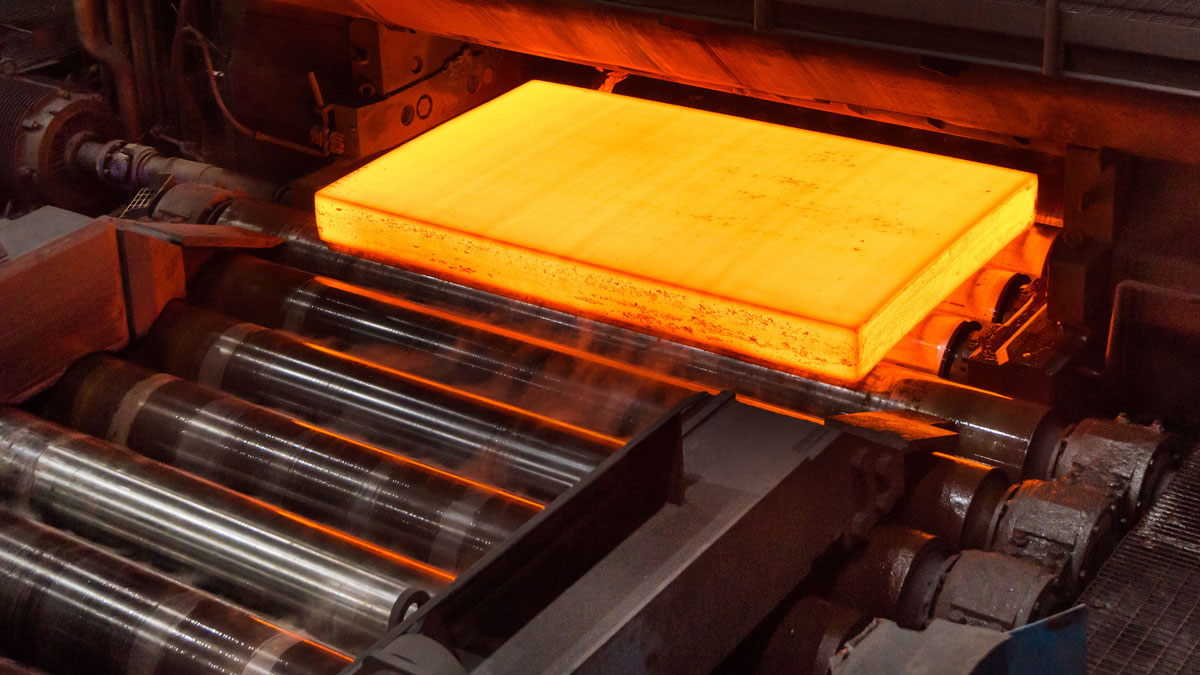

In 2026, SSAB plans to supply the market with fossil-free steel at a commercial scale after the conversion of its Oxelösund blast furnaces to an electric arc furnace and by using HYBRIT technology, which replaces coking coal, traditionally needed for iron ore-based steelmaking, with fossil-free electricity and hydrogen. This process virtually eliminates carbon dioxide-emissions in steelmaking.

“We are extremely happy to welcome Mercedes-Benz as a partner for fossil-free steel products. Together, we are building an entirely fossil-free value chain all the way to the end customer,” said Martin Lindqvist, President and CEO of SSAB. “We are proud to reduce global carbon dioxide-emissions in collaboration with our new partner.”

SSAB, LKAB and Vattenfall created HYBRIT, Hydrogen Breakthrough Ironmaking Technology, in 2016, with the aim of developing a technology for fossil-free iron- and steelmaking. In August 2021, SSAB was able to show the world’s first fossil-free steel plate made from hydrogen-reduced iron produced at HYBRIT’s pilot plant in Luleå, Sweden, an essential step toward a completely fossil-free value chain for steelmaking.

Green Mercedes-Benz steel supply chain

Mercedes-Benz takes every opportunity to reduce emissions quickly and sustainably. By the end of the decade, the company will be ready to go all-electric – everywhere market conditions allow. With this strategic step from ‘Electric first’ to ‘Electric only’, Mercedes-Benz is accelerating the transformation to an emission free and software-driven future.

By 2039 at the latest, the Mercedes-Benz new passenger car fleet will become CO2 neutral along the entire value chain, including the supplier network. Together with all its steel suppliers, the company pursues the goal of a green steel supply chain. In doing so, Mercedes-Benz is deliberately focusing on avoiding and reducing CO2 emissions instead of compensation. The partnership with SSAB is another important step towards this goal, with which the company accelerates the development and production of CO2-free steel in Europe.

Using green steel in vehicles in 2025, reducing its carbon footprint

Mercedes-Benz is the first car manufacturer to take an equity stake in Swedish start-up H2 Green Steel (H2GS) to introduce CO2 free steel into series production. Together with its steel suppliers, the company is retooling its supply chain to focus on the prevention and reduction of CO2 emissions rather than compensation. The partnership with HSGS is another step towards CO2 neutrality, which Mercedes-Benz is pursuing as part of Ambition 2039, its goal to achieve a fully connected and CO2 neutral vehicle fleet in 2039 – eleven years earlier than the EU legislation requires.

“With an equity stake in H2 Green Steel, Mercedes-Benz is sending an important signal to accelerate change in the steel industry and increase the availability of carbon-free steel. As a first step, we are investing a single-digit million amount. As a preferred partner of the start-up, we will be launching green steel in various vehicle models as early as 2025,” says Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG; responsible for Daimler Group Research and Mercedes-Benz Cars COO. A Mercedes‑Benz sedan is for example made from about 50% steel, which accounts for about 30% of CO2 emissions in production. With the partnership, Mercedes-Benz is actively and consistently tackling one of the biggest challenges in the automotive industry on the road to CO2 neutrality.

CO2 free manufacturing technology

By using a new, innovate manufacturing process, the production of steel at the supplier level is CO2 free. By contrast, steel produced using a classic blast furnace, emits an average of more than two tons of CO2 per ton. In the new process, the supplier uses hydrogen and electricity from 100 % renewable energy sources instead of coking coal in steel production. The hydrogen serves as a reduction gas, which releases and binds the oxygen from the iron ore. Unlike the use of coking coal, this does not produce CO2, but water. The supplier uses electricity from 100% renewable sources for the energy requirements generated in the manufacturing process.

Active engagement for a sustainable steel supply chain

Mercedes-Benz and all its steel suppliers are working consistently to reduce CO2 emissions in the steel supply chain on the way to producing green steel. In addition, the company is committed to a responsible steel supply, relying on the application of recognized standards and robust certificates. Mercedes-Benz is a member of the Responsible Steel Initiative and is actively involved in the development of a certifiable sustainability standard for the steel industry. The aim is to ensure environmentally friendly and socially acceptable steel production along the entire value chain.

CO2 neutral Mercedes-Benz supply chain

Mercedes-Benz pursues the goal of a CO2 neutral new car fleet along the entire value and supply chain. Suppliers representing more than 85% of Mercedes-Benz’s annual purchasing volume have already signed an Ambition Letter, agreeing to supply the company only with CO2 neutral products in the future. This includes important steel suppliers. At the same time, Mercedes-Benz is working with its partners to gradually increase the proportion of secondary materials in components and materials.

About H2 Green Steel

H2 Green Steel (H2GS) was founded in 2020, aiming to build a large-scale fossil-free steel production facility in northern Sweden. H2GS will produce 5 million tons of fossil-free steel by 2030. By doing this, the company will contribute to the decarbonizing of the European steel industry, one of the largest carbon dioxide emitters. H2GS will establish operations in Boden and Luleå. The founder and largest shareholder is Vargas, which is also co-founder and one of the largest shareholders in Northvolt.

Daimler sustainable recognition 2021

Ola Källenius, Chairman of the Board of Management of Daimler and Mercedes-Benz, and Martin Daum, Member of the Board of Management of Daimler and Chairman of the Board of Management of Daimler Truck, have honored the American steel supplier Big River Steel (BRS) for the exceptionally sustainable production of steel. By using recycled steel scrap and renewable energy, Big River Steel can reduce the CO2 emissions for Mercedes-Benz products in steel manufacturing by more than 70% compared to the traditional blast furnace route. In addition, the partner has set up a closed cycle in which the sheet-steel offcuts generated during production are fully recycled. The Big River Steel plant in Osceola, Arkansas, is the first steel production facility to achieve LEED (Leadership in Energy and Environmental Design) certification. Steel is a core component in vehicle construction and is very energy-intensive to produce.

“We are well on track for executing our sustainable business strategy. In close cooperation with our suppliers, we sharpened our focus on sustainability along the entire supply chain. Together we want to keep exceeding the expectations of our customers by taking technology, quality, and sustainability to a new level,” Ola Källenius said.

Emission-free mobility is a corporate goal for Daimler. To this end, the company is pushing ahead vigorously with the process of transformation. Climate neutrality can only be achieved together with suppliers and other partners. The car manufacturer awards special achievements on the part of its suppliers in the interests of sustainability.