BLUESPARK® Wireline Production Enhancement

A Pioneering Advancement in Energy Industry Innovation

In the dynamic landscape of the energy sector, innovation remains paramount, and Blue Spark Energy Inc. stands at the forefront of this evolution. With an increasing emphasis on cost-efficient and sustainable solutions for production enhancement, Blue Spark Energy offers a ground-breaking production enhancement and wellbore clean-up technology adaptable for wireline or E-Coil deployment.

Strategic production enhancement: A choice for operators

Operators seeking to amplify production generally have two primary strategies: embark on capital-intensive drilling campaigns to initiate new wells or optimize and extend the productivity of existing wells. The financial outlay and inherent risks associated with drilling new wells often overshadow the benefits. Recognizing this challenge, Blue Spark Energy has pioneered an innovative technology, eliminating the necessity for mechanical, chemical, or explosives-based methodologies to boost production.

Since its establishment in 2011, Blue Spark Energy has expanded its global footprint with ongoing onshore and offshore projects. The state-of-the-art downhole technology empowers operators to enhance their wellbores economically and safely using either e-line or e-coil, substantially reducing the industry’s carbon footprint compared to conventional methods.

Operational mechanism: Harnessing power efficiently

At the core of BLUESPARK® lies a straightforward yet powerful equation: power equals energy over time (P=E/t). Utilizing a minimal electrical charge, BLUESPARK® generates a targeted, potent hydraulic impulse, effectively clearing the wellbore and reservoir area. This high-power shockwave, travelling at over 1,500 meters per second, is succeeded by a 10,000-psi high-pressure pulse. Remarkably, BLUESPARK® achieves this with an energy equivalent to a mere tablespoon of orange juice while creating a power output of 240 megawatts. A distinguishing feature of BLUESPARK® is its ability to replicate these pulses hundreds or thousands of times.

The tool suite: Comprehensive and customizable

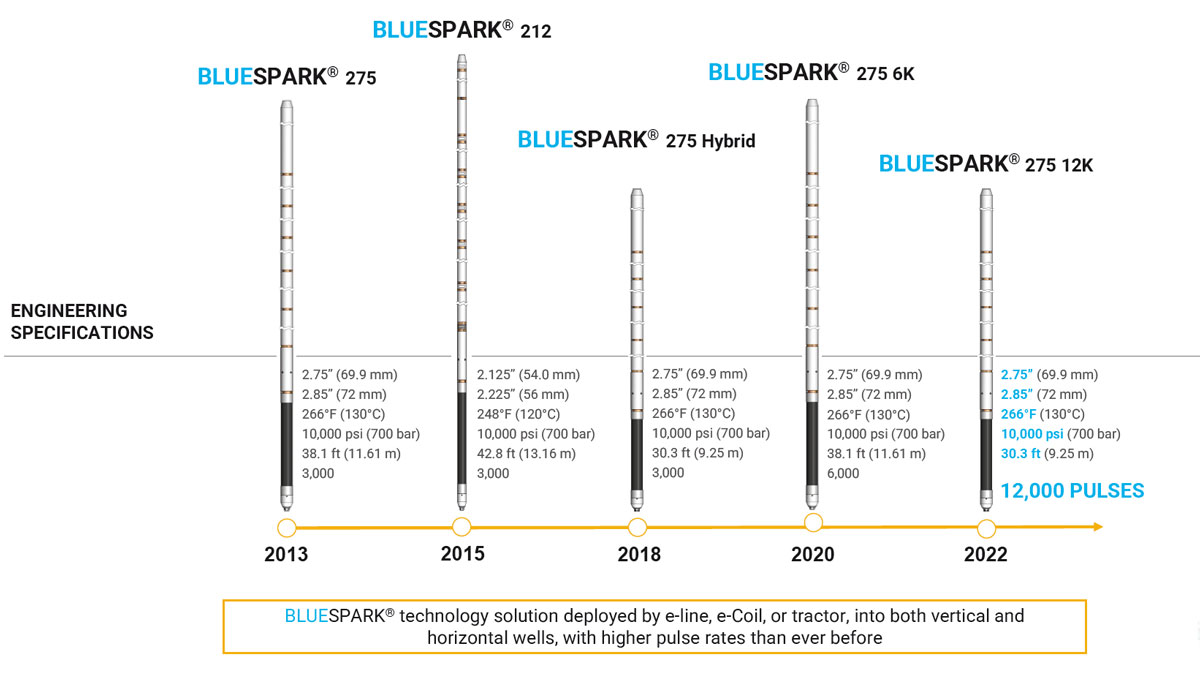

Each BLUESPARK® tool comprises of five integral components, all housing proprietary technology responsible for generating the spark and High-Pulsed Power (HPP) event. Firstly, the electrode section lies at the bottom of the tool. Positioned above the electrode section is the power amplifier linked to the energy-storing capacitors. Further up are both active and passive safety devices, culminating in the charge unit.

Available in various dimensions, ranging from 2 ½” to 2 3/8” OD, these tools offer diverse pulse capabilities. For instance, the 2 ½” tool accommodates up to 3,000 pulses per run, while the 2 3/8” tool can deliver between 3,000 to 12,000 pulses per run.

Upper completion

- Sub surface safety valves (Re-instate functionality)

- Wellhead valves (Re-instate functionality)

- Tubing clean for plug/straddle setting

Lower completion

- Sand screens (Production enhancement)

- Gravel packs (Production enhancement)

- Perforated liners (Production enhancement)

- Slotted liner (Production enhancement)

- SPM/Gas lift valves (Blockages)

- Sliding sleeves (Re-instate functionality)

- Tubing clean for plug/straddle setting

Beyond its treatment flexibility, BLUESPARK® technology offers additional advantages. It significantly reduces costs compared to conventional production enhancement methods, minimizes HSE risks by eliminating the need for hazardous materials like chemicals and explosives, and notably decreases the carbon footprint associated with traditional methodologies.

By necessitating only a single wireline unit and its associated personnel, BLUESPARK® further streamlines operations, reducing onsite time and overall costs. The tool’s efficacy spans a broad spectrum of applications, enhancing both new and existing wellbores and elevating operational efficiencies to unprecedented levels.

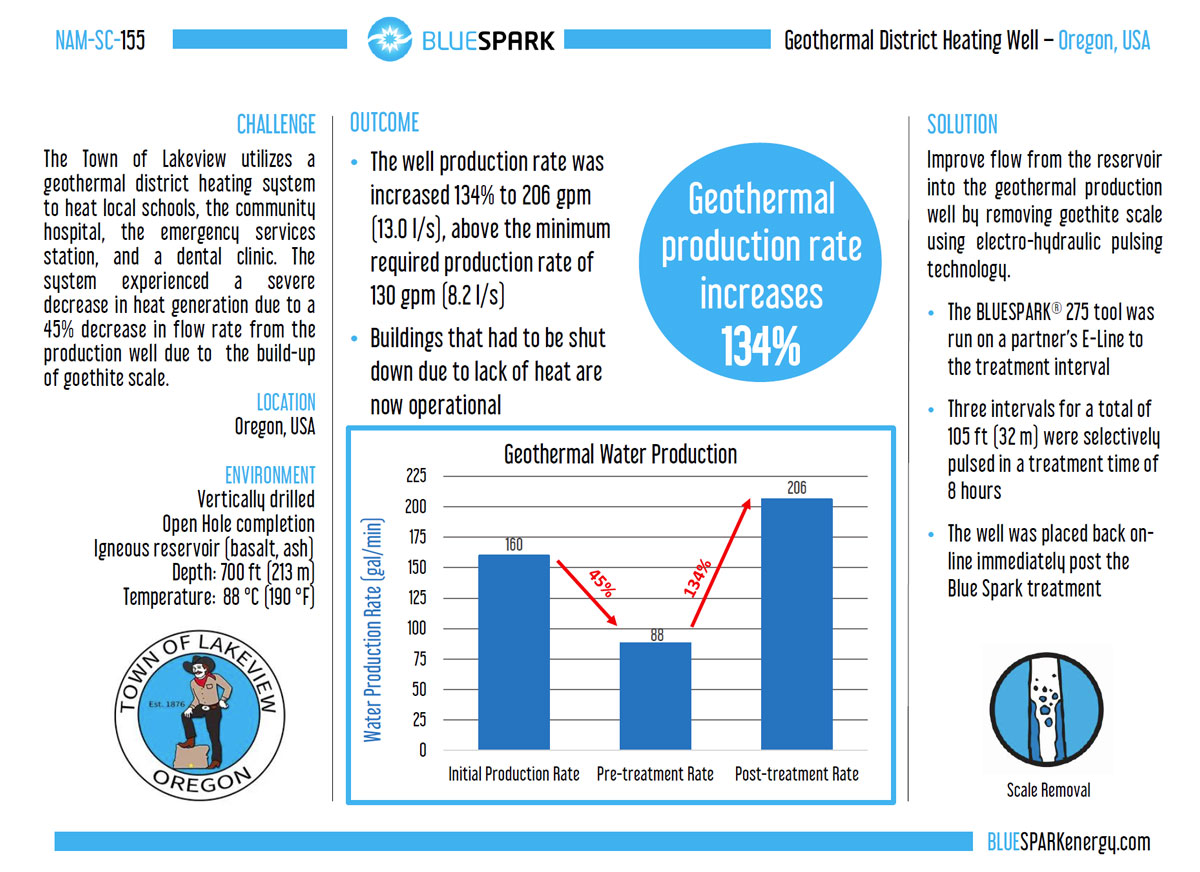

Geothermal energy applications: Extending the lifespan of wellbores through scale removal

Geothermal energy, a sustainable and renewable resource, plays a vital role in the global energy supply. To guarantee peak performance and longevity of geothermal wells, it is essential to implement a wellbore operation and maintenance strategy.

A fundamental component of this strategy is scale management, which is attributed to mineral precipitation from the brine during the reinjection and production process. The accumulation of scale deposits significantly impacts the lifespan and efficiency of geothermal wells by restricting fluid flow, thus reducing wellbore performance. To address these impacts for geothermal district heating (GDH) systems or power generation, it is essential to administer forward-looking maintenance plans before manageable fluids become unmitigated outages.

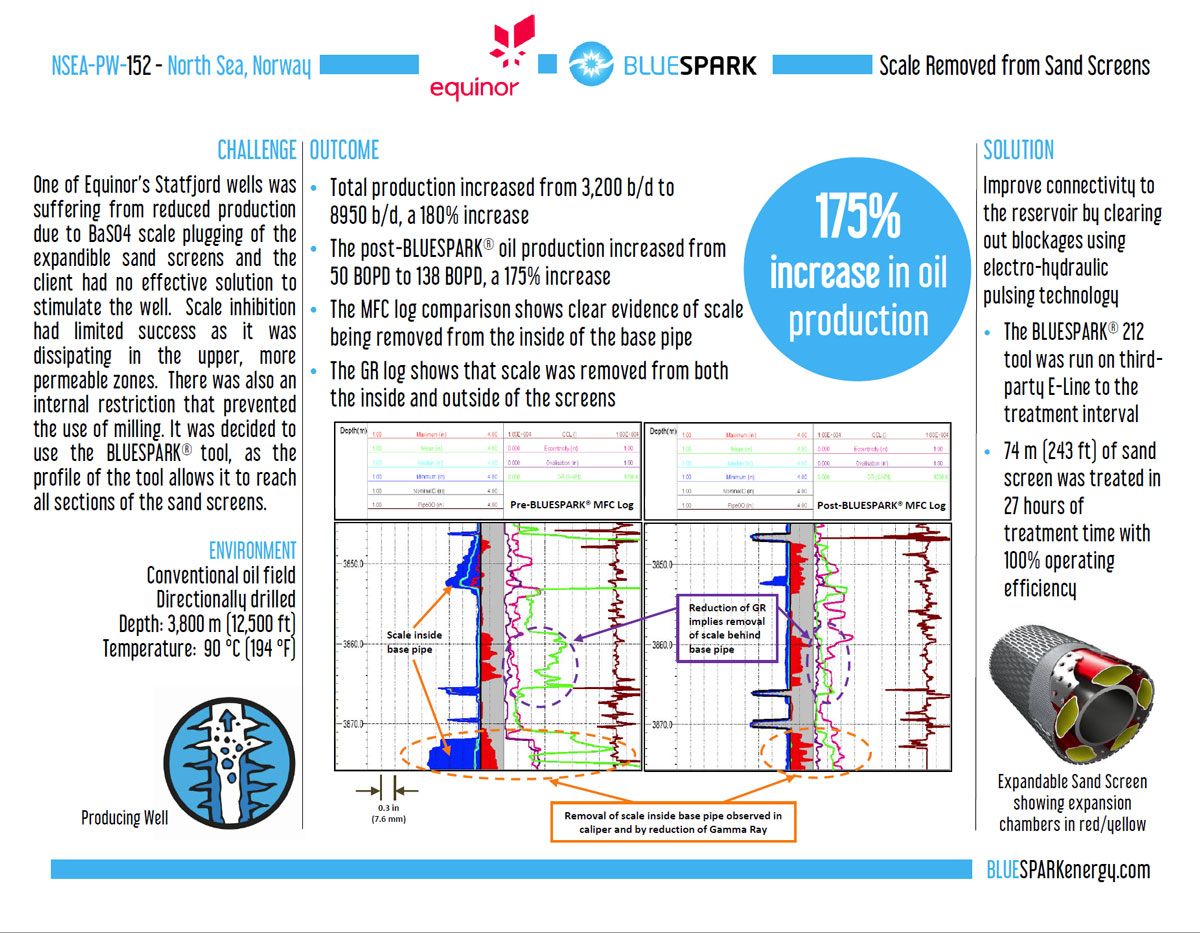

The BLUESPARK® technology is a sustainable solution that removes scale build-up while ensuring wellbore integrity. With the successful treatment of 39 scale types to date, it provides an effective solution for European countries to treat the most challenging scale deposits including magnesium-based silicates, carbonates, and iron-based corrosion products commonly present in geothermal wellbores.

If a BLUESPARK® wellbore maintenance strategy is implemented, ideal production and injection rates can be maintained because of the removal of flow impediments within the geothermal system. Implementing a proactive strategy for regular wellbore cleaning will extend the operational life of geothermal wells, reduce unplanned downtime, and ultimately increase the economic viability of a geothermal project.

Driven by our relentless pursuit to understand what is possible, we are challenging expectations and shattering conventions in the energy industry. Blue Spark Energy is inspiring energetic change as we continue to pave the way towards a sustainable future.