Equinor Announces Profitable Oil Discovery in the Oseberg Area

Norwegian offshore oil and gas company Equinor announces a profitable oil discovery related to Oseberg Vestflanken. The well was drilled by the Askepott rig and the discovery will soon be put on stream via the new, unmanned and remote-operated H platform on the Oseberg field.

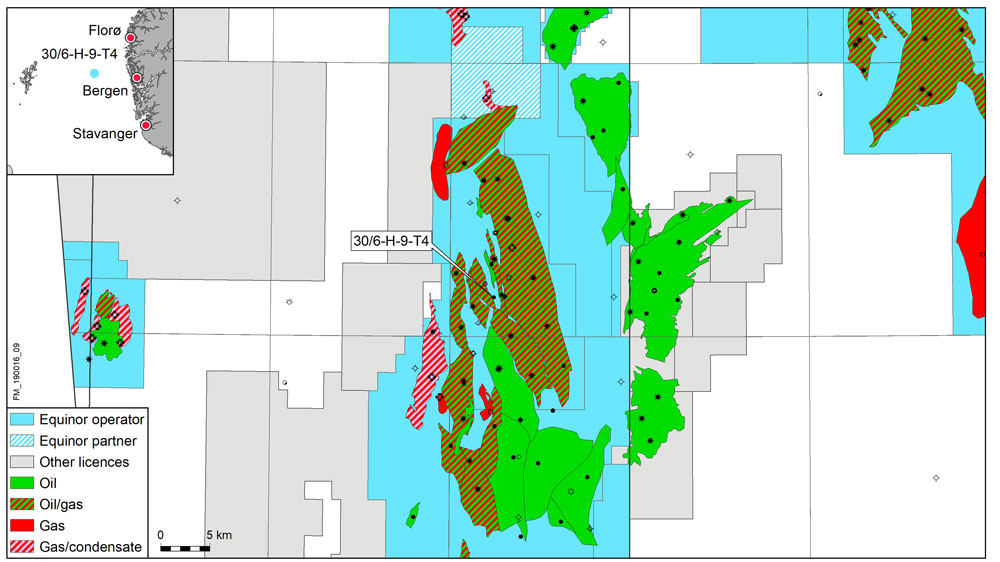

Included in the Oseberg Vestflanken phase 2 project, the exploration extension well 30/6-H-9-T4 proved a 112-metre oil column in a segment that has not been tested before. Oil was proven in the Statfjord formation in southern parts of the Alpha structure on Oseberg.

“Reservoir characteristics are excellent with high oil saturation. Recoverable resources are estimated at 22 million barrels of oil. The partners will consider water injection to further increase recoverable volumes,” Equinor representatives say.

“This discovery improves the Oseberg Vestflanken resource base. It can be put on stream with limited investments and adds significant value to the partnership. We are combining drilling of exploration and production wells to achieve highly profitable exploration wells at low cost,” says Gunnar Nakken, vice president for the operations west cluster of Equinor.

“Discoveries as these underline the importance of near-field exploration. Our ambition is to maintain profitable production from the Norwegian Continental Shelf (NCS) for several decades. A major contribution will come from wells that are drilled at low cost and close to existing infrastructure,” adds Nakken.

Equinor’s NCS roadmap focuses on developing the key hubs for sustainable and long-term value creation. The Oseberg area is seen as an important hub, offering a good resource base and possible future tie-ins from fields in the area.

“Having played a key role in the Norwegian oil adventure, Oseberg will continue to be important to us for a long time going forward. We are therefore pleased to see that recent investments in the area prove to be good business for both partners and society,” continues Nakken.

Oseberg is one of the big ‘elephants’ on the NCS. At the end of 2017, Oseberg was the third largest oil producer on the NCS having produced around 2.9 billion barrels of oil. Original development plans were based on an oil production of around 2.0 billion barrels. Current expectations are that 3.1 billion barrels of oil will be produced during the lifetime of the field.

Background

On 14 October, 2018 the Oseberg Vestflanken 2 field in the North Sea came on stream. Remote-operated from the Oseberg field centre, the new Oseberg H platform is the first unmanned platform on the Norwegian Continental Shelf. Recoverable resources are 110 million barrels, and the project was delivered far below budget.

The project was delivered at NOK 6.5 billion (2018 NOK), more than 20% lower than the cost estimate of the plan for development and operation (PDO). The breakeven price is reduced from USD 34 to below USD 20 per barrel, further strengthening a development that is already highly profitable.

Maintenance campaigns are to be carried out once or twice a year on the platform. While the Askepott rig is drilling wells through the platform, the maintenance personnel will stay on the rig. Afterwards the personnel will stay on a vessel hooked up to Oseberg H by a gangway.

The alternative to an unmanned wellhead platform would have been subsea wells. The new concept provides a competitive alternative in developing smaller discoveries.

“With Oseberg H we take a huge technological leap forward. The fully automatic, unmanned and remote-operated platform is digitalisation in practice, and I am proud of Equinor and its partners having chosen this in-house developed solution,” says Anders Opedal, Equinor’s executive vice president for Technology, Projects and Drilling.

“Oseberg H is a pilot and our first unmanned platform. We are further developing the concept and believe that the next version will be even more competitive,” adds Opedal.

The 11 wells on Oseberg Vestflanken 2 will be drilled by the Askepott jack-up rig owned by the Oseberg licence. Nine wells will be drilled through the Oseberg H platform and two through an existing subsea template. Pipelines and subsea equipment have also been installed.

The NCS operators have for a long time made considerable investments in a major infrastructure in connection with developing the big fields. Additional investments will yield a good return by phasing in smaller near-field oil and gas deposits through the existing infrastructure, and production of smaller volumes will be profitable while extending the field life and activity level of the big fields.

“With the Oseberg Vestflanken 2 development we keep expanding the massive infrastructure at the Oseberg field. This is a key contribution to renewing and securing long-term NCS activity,” says Arne Sigve Nylund, Equinor’s executive vice president for Development and Production Norway.

Even after 30 years of production Oseberg will play an important role on the NCS for decades to come, both as a major equity producer and as a hub for new additional volumes.

“In the Oseberg Vestflanken 2 development innovation and high value creation go hand in hand, in line with our plans for the NCS,” mentions Nylund.

Key facts about Oseberg

- Oseberg partners: Equinor (49.3% – operator), Petoro (33.6%), Total E&P Norge (14.7%), ConocoPhillips Skandinavia (2.4%)

- Having sold around 2.9 billion barrels of oil, Oseberg is Norway’s third largest oil producer throughout the times, following Statfjord and Ekofisk.

- Only Troll and Snøhvit of current fields in production have higher remaining gas reserves than Oseberg.

- Since production start in 1988 the Oseberg field has generated an estimated revenue of NOK 900 billion, corresponding to NOK 85 million per day.

- A large part of the Oseberg revenue is paid to the Norwegian state through taxes and the state’s ownership interest. This way the Oseberg field has contributed around NOK 450 billion in revenue to the Norwegian state.

- The Oseberg field consists of a main reservoir, Oseberg Main, and several minor reservoirs (satellite fields). Oil production from the main reservoir has so far been prioritised, however, export of the large gas cap is currently being escalated.

- Oseberg Main is producing through the Oseberg field centre and the Oseberg C platform.

- The Oseberg South, Oseberg East and Oseberg H platforms are producing from the satellite fields and transporting the oil to the Oseberg field centre. Gas from the satellite fields is injected back to the reservoir and produced at the Oseberg field centre.

- The gas is exported from the Oseberg field centre to markets in the UK and the Continent. Oil and condensate are piped to the Sture terminal in Øygarden north of Bergen.

- Production from the first unmanned wellhead platform on the Norwegian continental shelf, Oseberg H, started in the autumn of 2018.

The Oseberg area

The Oseberg Field Centre includes three platforms, Oseberg A, B and D, connected to one another with bridges, in the southern part of the Oseberg field, and the Oseberg C platform, which lies 14 kilometres north of the field centre.

Oseberg A is a concrete base platform with process equipment and living quarters, while Oseberg B sits atop a steel jacket and has drilling, production and injection equipment.

Oseberg D is a steel platform with gas processing and export equipment. It was connected to the Field Centre with a bridge in 1999.

Oseberg C is an integrated drilling, accommodation and production platform with a steel jacket.

Gas export started from the Oseberg Field Centre on October 1, 2000. This represented the beginning of a new era for the Oseberg field and for Hydro as an offshore operator.

Transport

Production from the Tune field (gas and condensate) is transported to the Oseberg Field Centre. Condensate is sent on to the land-based Sture terminal, and the gas injected into the Oseberg field.

Field Centre equipment is also used to handle oil and gas from the Oseberg Øst and Oseberg Sør satellite fields.

Oil from the Oseberg area is transported through the Oseberg Transport System (OTS) to the Sture terminal.

Oil from the Oseberg Sør, Oseberg Øst, Brage and Veslefrikk fields is also pumped through the same transport system.

The gas is transported to market via the Oseberg Gas Transport (OGT) pipeline and into the Statpipe and Vesterled systems via the Heimdal Gas Centre.

Location: Block 30/6 and 30/9, about 130 kilometres north-west of Bergen

Production start: 1 December 1988

Production: Oil and gas

Oseberg Sør

The Oseberg Sør platform in the North Sea commenced production in the winter of 2000.

The Oseberg Sør field, consisting of several structures south of the Oseberg field, is developed with an integrated drilling, accommodation and production platform on a steel jacket.

A sea-floor installation with four wells into the K geological structure is tied into the Oseberg Sør platform. In 2004, a new sea-floor installation started production from the J structure. There are 34 wells planned for the field.

Transport

The oil is transported via the Oseberg Field Center and Oseberg Transport System to the Sture terminal.

Location: Block 30/9, 13 kilometres south of Oseberg Field Centre

Production start: 5 February 2000

Production: Oil and gas

Oseberg C

Oseberg C lies 10 km north of the Oseberg field centre, and is an integrated accommodation, production and drilling platform with a steel jacket. Oil is produced from 18 wells. From three of the wells crude oil is sent in a multiphase pipeline to the field centre for processing.

Water is injected into three wells and gas into five wells to improve the oil recovery rate. Around 25,000 – 30,000 barrels of oil are produced from the field per day.

The oil is subject to a three-phase separation with pressure support in the reservoir from three compressors. Stabilised oil is transported to the Sture terminal via the field centre.

Transport

The oil is transported to the Sture terminal via the field centre

Location: 10 km north of the Oseberg field centre

Start-up: December 1991

Oseberg Øst

The smallest platform in the Oseberg area, Oseberg Øst, lies 25 kilometres north-east of the Oseberg Field Centre.

The field is developed with an integrated drilling, accommodation and production platform with equipment for first phase processing.

The oil goes through second and third phase processing at the Oseberg Field Centre, before it is transported in an oil pipeline to the Sture terminal.

Maximum output is about 75,000 barrels of oil per day. Water and gas are injected into the reservoir to boost recovery.

Transport

The oil is transported by pipeline via the Oseberg Transport System (OTS) to the Sture terminal.

Location: 25 kilometres north-east of the Oseberg Field Centre

Start-up: 3 May 1999

Facts about Oseberg Vestflanken 2

- Partners in the Oseberg Vestflanken 2 production licence: Equinor Energy AS (49.3%), Petoro AS (33.6%), Total E&P Norge AS (14.7%) and ConocoPhillips Skandinavia AS (2.4%)

- Location: In the North Sea some 8 kilometres north-west of Oseberg field centre

- Volumes: 110 million barrels of oil equivalent

- Depth: some 110-metre water depth

- Estimated productive life: until 2040