First offshore application for Siemens SGT-750 gas turbine

Siemens was selected to engineer, manufacture and commission the SGT-750 gas turbine-driven compression train for Statoil’s floating production, storage and offloading (FPSO) vessel located in the Johan Castberg oil field in the Barents Sea. The project represents the first offshore application for the SGT-750 gas turbine. Equipment delivery is anticipated mid-2019 with first oil planned for 2022.

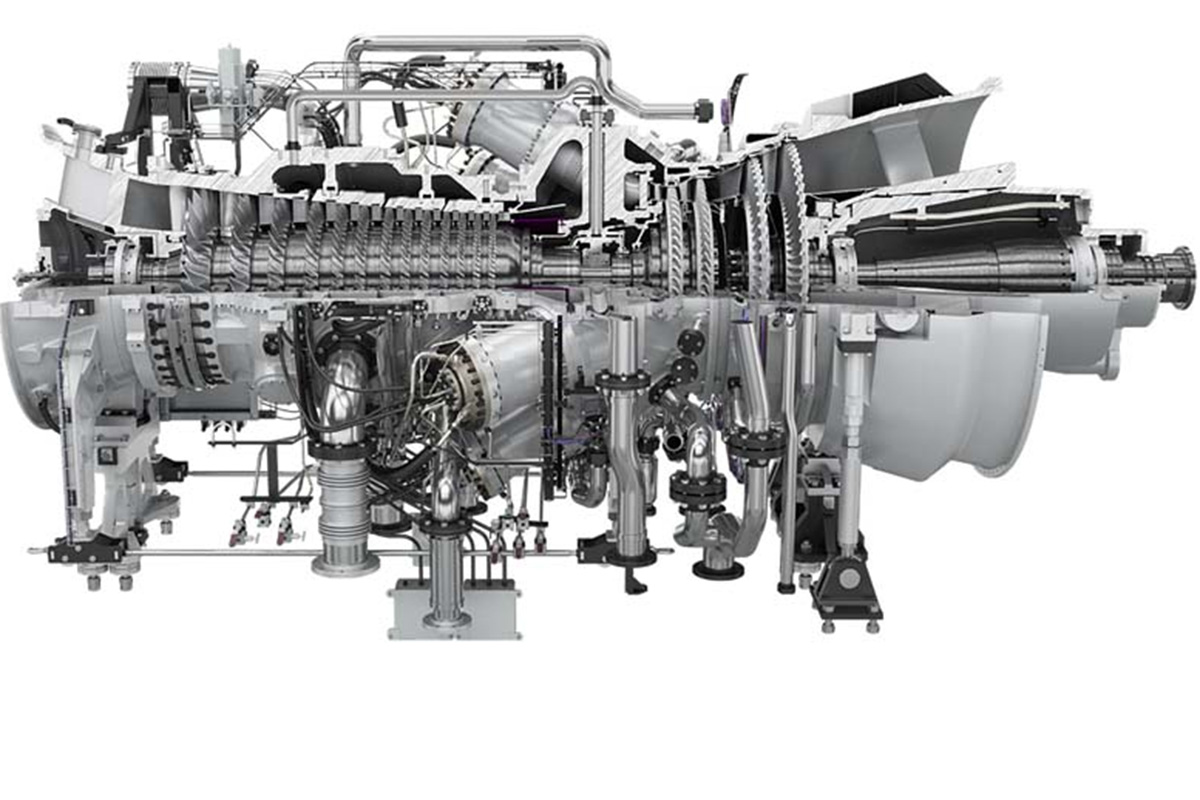

The SGT-750 gas turbine

The SGT-750 gas turbine enables long maintenance intervals which increases production uptime and profitability.

The equipment includes a 41-MW SGT-750 gas turbine that will drive two DATUM compressors operating in a tandem arrangement. The DATUM compressors, known for their high efficiencies, will reinject gas to pressurize the oil reservoir. Siemens will also supply a waste heat recovery unit to recover gas turbine exhaust heat that will be distributed as heated liquid to prevent ice build-up on key surfaces of the superstructure.

Like others in the oil and gas industry today, Statoil continues to seek solutions that will enable the oil giant to optimize production while minimizing environmental impacts. The SGT-750 gas turbine enables long maintenance intervals which increases production uptime and profitability, and is capable of driving the DATUM compressors without a speed increasing gearbox. These attributes, combined with the high efficiencies of the SGT-750 turbine and DATUM compressor, reduce total CO2 emissions and offer lowest total cost of ownership.

“This contract, placed as part of our Frame Agreement, exemplifies the confidence Statoil continues to place in us because of our proven track record of highly efficient, low-emission equipment for offshore production facilities,” said Matthew Chinn, Executive Vice President of the Dresser-Rand business New Equipment Solutions. “The performance of the mission-critical equipment for this project not only lowers the total cost of ownership but offers long maintenance intervals, which in turn reduces maintenance costs and increases production uptime,” he added.