Halliburton launches the e-cd™ Plus system

Halliburton released on April 18 the e-cd™ Plus system – a new technology that automates and enhances continuous circulation connections during drilling and tripping operations. Continuous circulation provides the uninterrupted flow of drilling fluid into the well throughout the process of adding or removing drill pipe joints to the drill string.

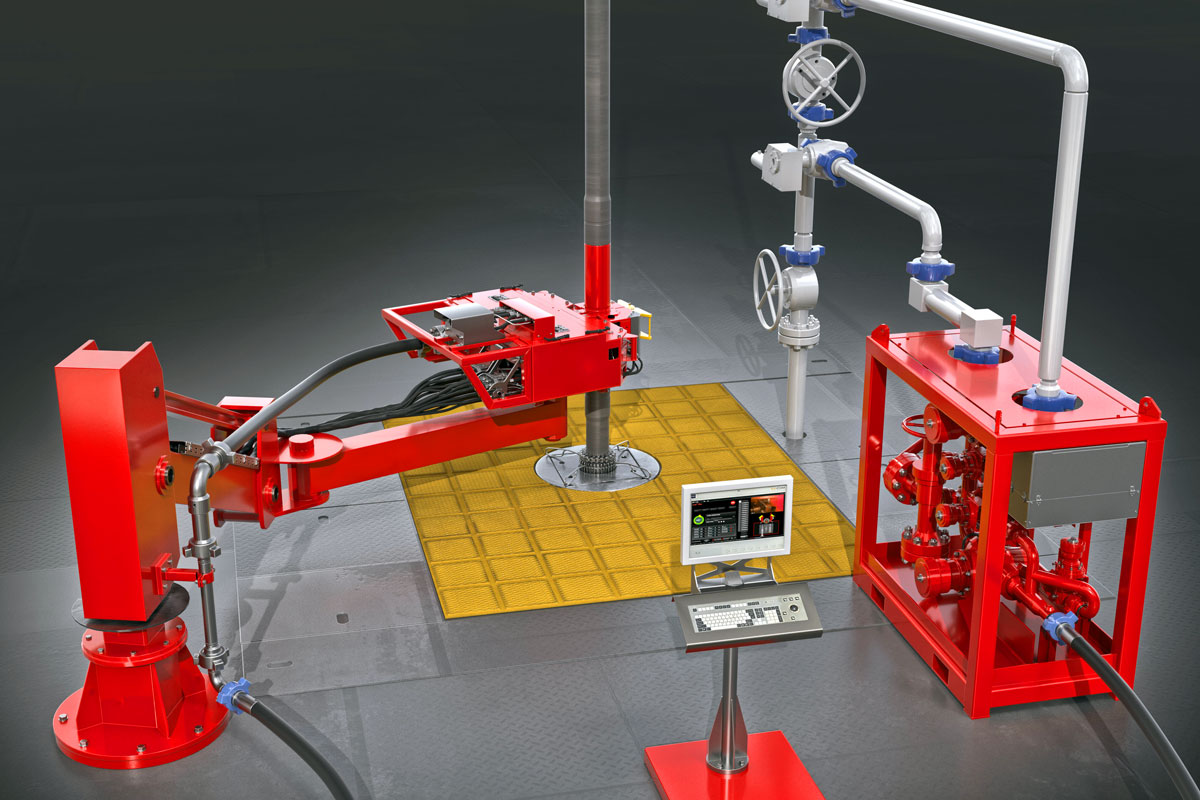

After connecting the e-cd™ Plus system to surface control equipment, a proprietary software remotely controls all steps of the flow diversion and side port connection process that is currently completed via manual human operation. The overall system maintains a small footprint and can reduce the number of rig personnel required to safely provide continuous downhole circulation.

The system also helps improve success in challenging projects such as wells with narrow pore pressure/fracture gradients by keeping bottom-hole pressure and fluid properties constant, cooling equipment in high-pressure and high temperature applications and providing continuous wellbore cleaning by movement of cuttings in extended reach wells.

“We designed the e-cd™ Plus system to meet the growing market demand for continuous circulation technology in highly regulated markets by improving safety, efficiency and reducing overall connection time to save valuable rig time,” said Daniel Casale, Vice President of Testing and Subsea. “With the automated system, not only is a dual pressure barrier maintained during operations, but it has the versatility to run either as a standalone solution or to be used in managed pressure drilling operations to help reduce risk in difficult wells,” he added.

On a recent project in the North Sea, an operator was previously unable to successfully reach target depth due to poor cuttings movement and wellbore stress. They deployed the automated diversion portion of the e-cd™ Plus system to provide continuous circulation over two well sections and approximately 6,800 feet of total open-hole drilling. The operator successfully reached total depth and cemented the liner in each section, helping eliminate the challenges that halted operation in the previous offset well.

About the e-cd™ Plus system

The e-cd™ Plus system enhances the process by replacing the manual connection procedure with an automated system that uses a delivery arm or overhead lift to attach a tool to clamp to the e-cd sub. Once the tool is attached, a remote station automatically controls all steps of the side port connection and flow diversion.

The e-cd Plus system maintains the benefits and case history of the manual e-cd system, but increases safety by removing personnel from the red zone in single barrier pressure applications, improves efficiency, and reduces overall connection time.

Once the flowline is connected to the sub, the entire process is computer controlled from a remote station in a safe environment, providing a live look at the operation and instantaneous feedback of all systems.

Automated operation with the e-cd Plus system provides:

- Controllability of system by various levels of automation depending on operational needs;

- Retained service quality and system track record by utilizing same e-cd sub design;

- Threaded engagement of the side port flowline for safe flow diversion;

- Undermount delivery arm or overhead lift line system delivery options to the drillpipe;

- Seamless integration with MPD operations and software without requirement to add additional surface back pressure during the connection.