How to Save Costs by Preventing Fluid Loss Effectively

Loss of circulation while drilling, is a problem faced by the drilling industry on a daily basis. Unfortunately, if these problems are not addressed accordingly, the results may induce non-productive time and compromise the well integrity. Which may require unplanned technical efforts and cost money to solve over and above what is budgeted/planned for.

Whilst many of the major drilling fluids companies supply their own line of LCM products, a number of specialized players have emerged to capitalize on an industry need for more innovative solutions to the costly problems. The products from said companies so far have had a relatively low success rate in fixing these drilling challenges cost effectively. The majority of wells drilling for oil and gas, in particular the deeper and deviated wells, will incur cost overruns due to drilling challenges caused by lost circulation and wellbore instabilities.

Therefore, there is room for innovation, to give operators significant cost savings and also enable drilling more undrillable formations where previous attempts have failed due to high formation pressures. Drilchem have developed a range of products that are eco-friendly and non-damaging to producing formations. These products are based on patented and specially engineered organic fiber technology, proven to be highly efficient in dealing with wellbore instability.

New ways to reduce cost

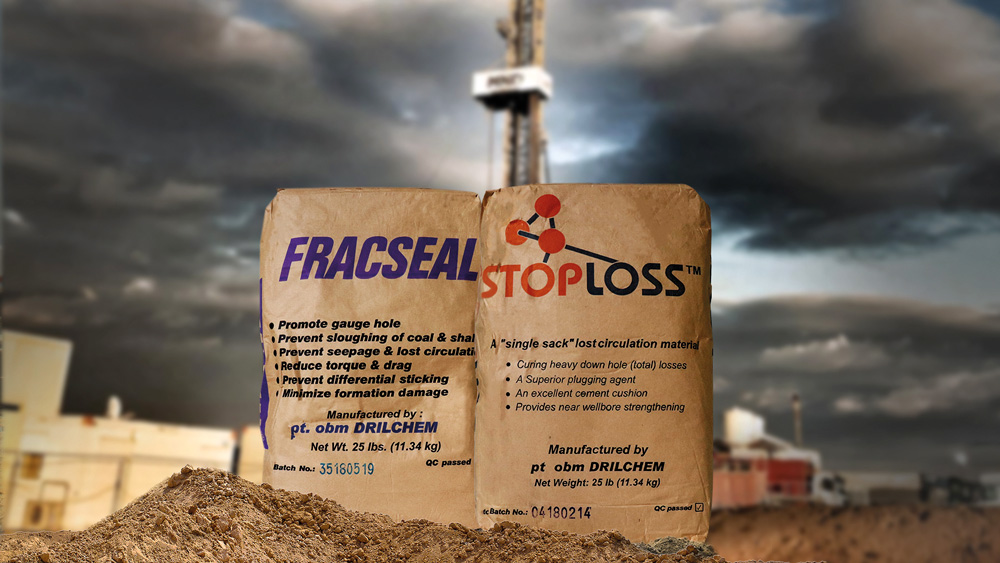

Operators are looking for new ways to manage known risks and know there are considerable savings to be had from trying things differently. On a recent project, Drilchem was able to contribute to the Operator saving two casing strings by careful analysis of offset well data and the introduction of Drilchem products through a critical fluid screening process. This was done to manage the risk of losses and formation breakouts, and the cost savings from not using the two casing strings made the project a unique success story for the Operator. These products, when added to the drilling fluids, can stabilize highly reactive shales, prevent severe loss of circulation and assist in stabilizing the wellbore from high formation pressures. Operators can thereby achieve longer OH sections and better hole conditions with a good chance of reducing the number of casing strings. Fracseal is used to enhance wellbore stability and Stoploss is used to deal with cases of severe lost circulation.

Fracseal is manufactured from micronized organic cellulose materials and can be used to optimize filtercake performance creating a lattice like network on the borehole wall effectively sealing off the formation with a very thin filtercake. In doing this the apparent fracture gradient can be increased by sealing the fracture and isolating the fracture tip so to prevent it from propagating and resulting in a loss scenario.

Stoploss has been designed specifically for severe to total loss situations, where the only alternatives to curing the losses are setting a cement plug and possibly sidetracking. The effectiveness of the product has been highlighted in geomechanics studies showing its ability to seal fracture widths estimated at 50 cm in diameter.

It is estimated that 15% to 20% of the total costs of drilling operations is accounted for by drilling fluids and that 2 billion USD per annum is spent fixing problems caused by loss of circulation. It’s a competitive market and the cost savings are significant when the right strategy is chosen.

Everyone should be focusing on 0 losses and 0 NPT. For Operators, the above drivers underscore the potential for finding new synergies between primary mud suppliers and specialized companies/operators whose products are eco-friendly, easy to transport, use and handle at the rig site, and that ultimately will cut costs and optimize drilling budgets.

Dosco PetroServices is the official & exclusive distributor of Drilchem products for the CEE Region. If you are interested and require more information please don’t hesitate to contact us.