Neptune Energy’s VR Pilot Developed by PaleBlue for Astronauts on Gjøa Platform

Neptune Energy has completed a virtual reality pilot on its operated Gjøa platform in the Norwegian North Sea, enabling teams to make highly realistic virtual visits to the facility. The technology, developed by PaleBlue and used to train astronauts travelling to the International Space Station, will reduce the need for offshore travel, lower costs and associated emissions and support safe operations.

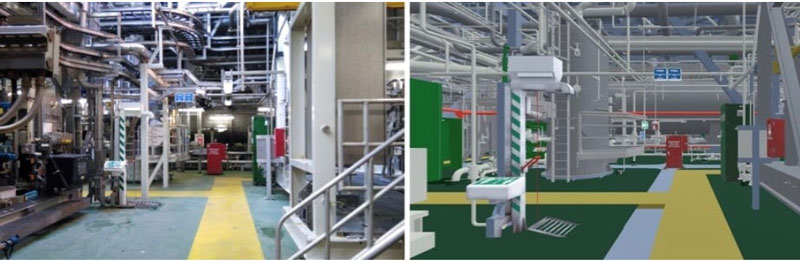

It is the first time PaleBlue’s technology has been applied to an offshore installation of such complexity. Using a VR headset, offshore workers interact with a realistic 3D model of the Gjøa platform from onshore.

“The new virtual reality solution allows employees and contractors to build up knowledge and awareness of the complex multi-level facility without the need to travel. Planning work operations will be safer and more efficient,” Martin Borthne, Director of Operations in Neptune Norway, said. “The initiative will together with other projects see an estimated reduction of 30 offshore trips per year. We expect this to grow in the years ahead as digitalisation further enhances collaboration over distance, bringing immediate access to expertise and enabling preparation of activities to be carried out from onshore,” he added.

The project is set to create a familiarization and safety training simulator in Virtual Reality, allowing to build up knowledge and awareness of the complex multi-level facility without the need to travel, which will be a great cost saver. The specialists using the VR solution would then be able to get to know the Gjøa oil platform prior to their first trip offshore, and thus become more effective in their work tasks while on the actual job. Neptune Energy has a strong focus on optimizing all aspects of the HSE&Q area for their employees. This investment in the VR-training simulator is an important contribution to this. In addition Neptune Energy is very conscious of their impact on the environment. The reduced travelling will be a considerable contribution to save greenhouse gases, and one of several areas aligned with the UN’s Sustainable Development Goals.

“The restrictions and all the consequences of COVID-19 have introduced challenges to operations for many companies. By doing the familiarisation training in a virtual world, even from home, companies can overcome travelling restrictions, save time, costs, and emissions, and will be 100% prepared with crucial knowledge of the facility when they physically arrive offshore,” Egil Thomas Andersen, Account Director at PaleBlue, explained.

Digitising operational assets to improve safety, efficiency and reduce environmental impacts is a key component of Neptune Energy’s digital strategy. The company has created digital twins of platforms in the Norwegian, UK and Dutch sectors of the North Sea, enabling offshore site inspections and planning work to be carried out onshore. Neptune also uses laser scan technology to carry out detailed engineering work for subsea productions developments which will be tied back to Gjøa.

PaleBlue is the leading provider of immersive technologies and training solutions. The company’s focus is on achieving excellence by delivering value-driven solutions enabled with AR and VR technology. PaleBlue 3D simulators are built for the real world and help businesses worldwide better prepare for real-life situations and emergencies.