N’GENIUS Series™ to Change the Way Oil & Gas Sector Views Austenitic Stainless Steels

A ground-breaking new series of high strength austenitic stainless steels – N’GENIUS Series™, has been developed that will transform how materials are specified and utilised across the oil and gas sector.

The N’GENIUS Series™ represents the total reinvention of conventional austenitic stainless steels and has been specifically developed to out-perform, supersede, and supplement the majority of existing grades in the 300 Series, the corrosion resistant alloy (CRA) line pipe grades currently available for selection in the API Specification 5LC and the DNV-ST-F101 standard, plus the CRA Oil Country Tubular Goods (OCTG) in the API Specification 5CT for Casing and Tubing.

Dr C.V. Roscoe, inventor of the original 25Cr super-duplex stainless steel and CEO of N’GENIUS Materials Technology, explained: “The extensive range of alloy types, variants and grades in the N’GENIUS Series™ of High Strength Austenitic Stainless Steels have strength properties equivalent to duplex and super-duplex stainless steels, ductility and toughness levels normally associated with conventional austenitic stainless steels but with far superior corrosion resistance to suit all major oil and gas projects.

The engineering significance of the N’GENIUS Series™ for onshore and offshore CRA pipeline projects, subsea production systems and OCTG for CRA casing and tubing is truly astounding.

Also design engineers considering the best way to develop major offshore projects utilising potential combinations of Platforms, FPSO vessels or FLNG vessels can take advantage of the high strength properties of the N’GENIUS Series™ to reduce topside weight for all the piping systems, modules, engineered products and fabricated equipment. This enables the engineering design and construction of the projects to be optimised thus leading to an overall reduction in the costs of the projects.”

What makes N’GENIUS so ingenious?

Patent protected in 30 countries globally, the N’GENIUS Series™ provides a unique combination of unprecedented strength compared to conventional 300 Series grades of austenitic stainless steels, vastly improved corrosion resistance and excellent toughness at sub-zero temperatures.

These and other key engineering design characteristics will allow an infinite range of product forms and ancillary equipment to be designed, specified, manufactured, and supplied with the objective of reducing wall thicknesses and overall size, using less material, and producing lighter products. This makes products easier to handle and transport to site, leading to weight savings, an overall reduction in construction and project costs and – perhaps most importantly – contributing to lower carbon emissions and a greener world.

The superior corrosion resistance of the N’GENIUS Series™ will also improve the through-life costs and extend the service-life and environmental sustainability of these projects.

No more compromising on materials

The unique combination of mechanical strength and corrosion resistance properties of the N’GENIUS Series™ will fundamentally change the materials selection philosophy for oil and gas industry projects throughout the world, including all major upstream, midstream, and downstream developments.

At present, there isn’t a particular CRA pipeline material that totally satisfies all the requirements of design engineers, process engineers, corrosion specialists and project engineers for major CRA pipeline projects in a wide range of service conditions including high pressure, high temperature (HPHT) developments and process media environments containing various levels of Chlorides, CO2, H2S and other constituents. Until now.

Total system capability

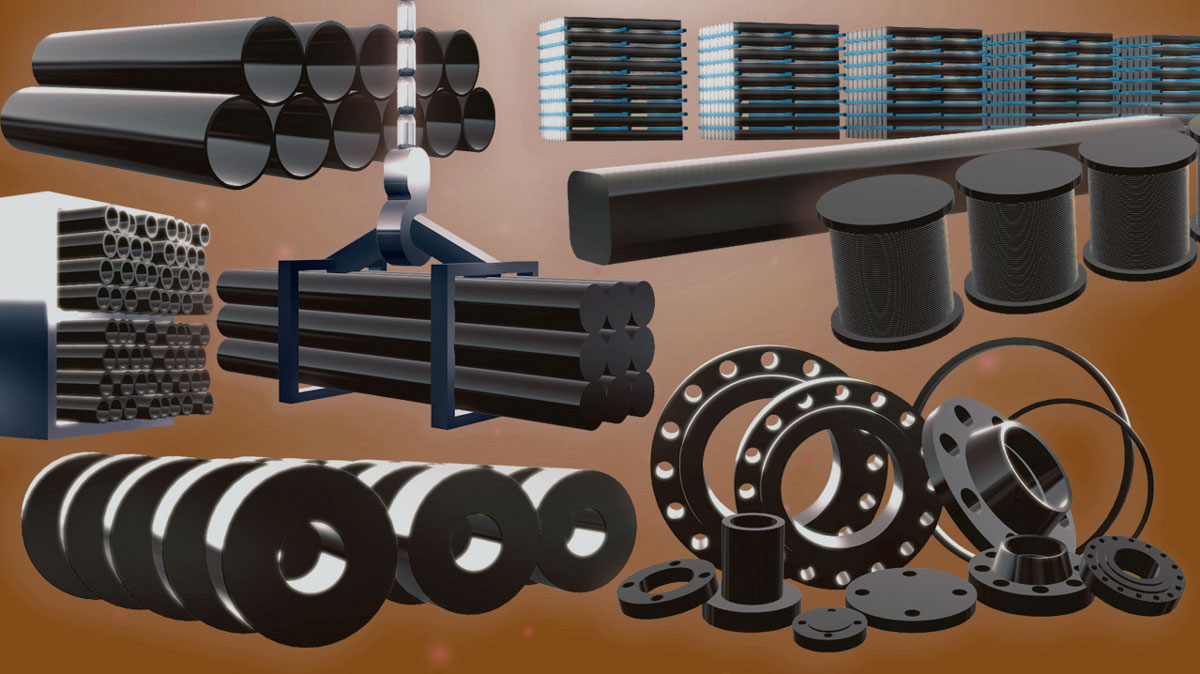

In terms of oil and gas production system design, the N’GENIUS Series™ has been developed to be the total system material solution. A vast array of wrought and cast products and equipment can be manufactured and supplied in the N’GENIUS Series™ for onshore and offshore oil and gas production systems.

Subsea umbilicals, catenary risers and flowlines, manifolds, subsea bundles, well heads, fittings, flanges, compact flanges, hub connectors and engineered products such as pumps and valves are among these products and equipment. As are fabricated products such as offshore topside systems including spools, modules, static risers, process piping systems, seawater cooling systems, firewater systems, filtration systems, heat exchangers and various ancillary equipment including tanks, vessels, and structures.

A pipeline technology without limits

The N’GENIUS Series™ of CRA line pipe grades, which can be available in both seamless and welded product forms, will provide a virtually unlimited choice of high strength austenitic stainless steels for industry specialists to select from and help satisfy the growing demand for high-performance stainless steels that are stronger, last longer and are better for the planet.

Specifically, the N’GENIUS Series™ of CRA line pipe grades will address the need for a much wider selection of CRA line pipe materials that are suitable in a wide range of service conditions and process media environments for all types of onshore projects and offshore projects in shallow, deep and ultra-deep water that can be installed using the various installation methods including S-lay, J-lay, Reel-lay and subsea Bundle installation techniques.

The ideal material choice for OCTG

Reaching new reserves, operating in challenging service conditions and exposure to increasingly aggressive process media puts material choice for OCTG into sharp focus and further highlights the enormous benefits of the N’GENIUS Series™.

Perfectly suited for OCTG casing and tubing, the high strength of the N’GENIUS Series™ helps overcome the dilemmas caused by elevated temperatures, high pressures, and higher mechanical loads, whilst its improved corrosion resistance provides a robust defence even in harsh process media environments containing various levels of Chlorides, CO2, H2S and other constituents.

The N’GENIUS Series™ also ensures the very best resistance to hydrogen embrittlement and, in particular, stress corrosion cracking (SCC) in aggressive media environments which can often be a major obstacle for OCTG.

For design engineers – where the long and safe operation of wells is key – the availability of durable, pressure and corrosion resistant downhole casing and production tubing is essential, and the alloy types, variants, and grades of the N’GENIUS Series™ provide the answer.

The N’GENIUS way

To assist engineers at the conceptual design stage, pre-FEED and FEED stages and detailed engineering design stages of the materials selection and specification process, Material Data Sheets (MDS) have been formulated for a wide range of product types to establish the minimum criteria for the manufacture, inspection, testing and control in accordance with International Codes, Standards and Specifications for each Alloy Type, Variant and Grade in the N’GENIUS Series™.

The N’GENIUS Series™ is available to be manufactured under licence by premier manufacturers of stainless-steel products.

About N’GENIUS Materials Technology

N’GENIUS Materials Technology, based in Cheshire, England in the United Kingdom, is a materials technology company, specialising in the invention of next-generation stainless steels. The N’GENIUS Series™ possesses a unique combination high mechanical strength along with superior resistance to corrosion. These properties provide engineers with superior engineering design characteristics to optimise the development of major projects throughout the world. The N’GENIUS Series™ of High Strength Austenitic Stainless Steels is the complete reinvention of austenitic stainless steels, designed specifically to out-perform, supersede and supplement many of the conventional 300 Series grades and the existing grades that are currently available for selection in the API Specification 5LC for CRA line pipe and DNV-ST-F101 standard for submarine pipelines systems along with the CRA Oil Country Tubular Goods (OCTG) currently available for selection in the API Specification 5CT for Casing and Tubing.

25Cr Super Duplex was invented by Dr Ces Roscoe whilst tasked by his then employer – Mather+Platt – with studying the effect of various alloying additions on the mechanical properties and corrosion resistance of Duplex Stainless Steels. The new material became the first ever ‘super duplex’ stainless steel. Ownership of the technology has changed hands over the years, but it remains one of the leading super duplex stainless steels available in the market.

Source: Press release

Key engineering features of the N’GENIUS Series™

- High mechanical strength with excellent ductility and toughness

- Higher allowable design stresses

- Superior resistance to general corrosion, localised corrosion, erosion corrosion, stress corrosion cracking and corrosion fatigue relative to conventional austenitic stainless steels

- Excellent toughness at ambient, sub-zero, and cryogenic temperatures

- Distinct minimum pitting resistance equivalent values for each alloy type, variant and grade designation.