Oil & Gas Clean Energy Technology Continues to Advance

By Maureen McCall

In this climate of conventional energy company mega-mergers and acquisitions in both the U.S., and Canada creating renewed interest in production, conventional energy tech advancements are the key to managing a reliable energy supply with lower emissions, efficient budgets, and improved safety.

New tech advancements by an Alberta, Canada company have recently received great recognition from an energy industry technical association. In November 2023, Wireline Abandonment and Completion Corp (WACORP) was awarded the 2023 ICoTA Canada Innovation of the Year Award from the Intervention & Coiled Tubing Association – ICoTA Canadian Chapter for WACORP’s KWAT rigless abandonment technology. ICoTA is a global association with chapters in the U.S., Canada, Europe, Latin America, the Middle East, and North Africa.

WACORP- the Wireline Abandonment and Completion Corp was founded in 2016 to improve and streamline the abandonment of oil and gas wells in Alberta in response to significant demand for the zonal abandonment of suspended wells. However, wireline technology has significant applications for emission’s reduction and revival of older producing wells that make it ripe for applications needed by acquiring companies.

As companies make significant acquisitions, they also acquire new liabilities. Wireline technology has direct applications for abandonments. After recently using WACORP’s wireline technology in Canada, Dustin Pashko, Lead Wells Supervisor at Shell Australia commented: “We recently utilized KWAT to set and pressure test an abandonment plug above the lower set of perforations in a two-zone well in Northeast BC. Being able to do this on wireline saved us over $10k/30% compared to doing this the conventional way. Considering the number of legacy wells that we need to abandon in the near future with dual completions and/or minor casing leaks, integrating this tool into our abandonment practices is going to result in significant cost and time savings.”

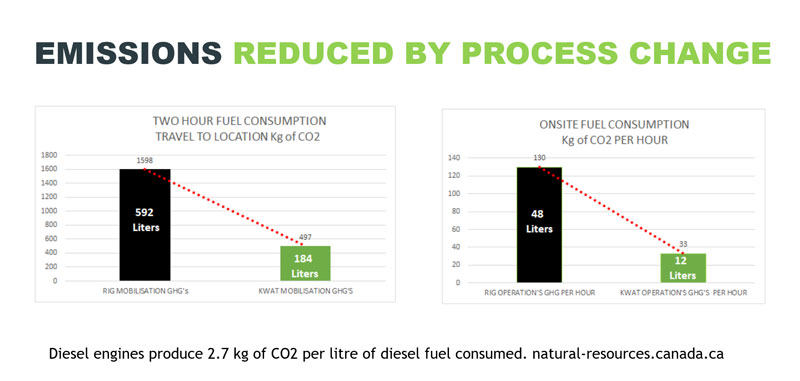

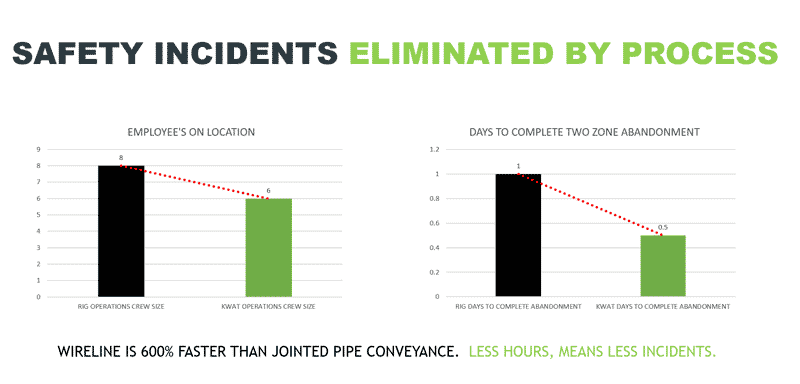

As well as for abandonments, wireline technology has direct applications for workovers and the remediation of wells with high surface casing vent flow. It is a more efficient method, requiring shorter timelines, with a lower number of crew, and fewer trucks and equipment. The result is significantly lower emissions and lower costs- less time spent on the well, lower budgets, less equipment and manpower and improved safety due to the nature of WACORP’s technology.

As an example of the time and cost reductions, Nick Kozak, Completions Engineer Crew Energy stated: “Crew Energy utilized the KWAT tool during our abandonment operations. The objective to abandon the completed interval was completed 0.5 days earlier and saved approximately $8000 in service rig, supervision, rentals, and other auxiliary costs.”

In traditional abandonment and workover practices, pressure is applied at the surface, which has inherent safety risks, whereas wireline employs pressure applied downhole and uses fewer employees on location. In addition, the equipment is on site for fewer hours creating lower safety risk.

Using wireline can effectively reduce emissions remediating a surface casing vent flow because it uses one wireline truck instead of a rig and trucks. But it also has a new application for workovers. Over the past five years interest in bypassed pay zones has picked up for companies after years of drilling horizontal wells. Horizontals have high netback but they’re very expensive and they produce for a shorter period of time. There is a new realization that producing some of the bypassed pay zones can increase the profitability of existing wells.

“Horizontal wells are massive to produce, but they have a short lifespan,” Peter Knight, WACORP president says. “Older wells don’t produce as much in a vertical application because they just don’t have as much pay zone, However, they last for a long time and it’s consistent revenue. It’s really expensive to drill a brand-new well. Horizontal wells have a very high netback but for a shorter period of time. Operators have vertical wells in their inventory, and they know that they have zones that still have a significant amount of resource life left in them. So, it makes financial sense to move up the hole and try to produce that instead of abandoning the wellbore. companies that have recently acquired another company are looking at existing wells, and how to maximize production.”

The company has expertise working in multiple areas of operations from NEBC to the U.S. border in Alberta and Saskatchewan. Knight says accessing bypassed pay zones to rejuvenate mature fields has applications for offshore, deep-water wells as well as onshore and WACORP is scaling up their technology – working on applications using multiple casing sizes including larger offshore casings.

“We’ve hit all the technical milestones,” Knight says. “This year, we’ve gotten over 3000 meters vertical, or up over 110 degrees Celsius, and experienced massive hydrostatic pressure against the tools. Our challenge now is to scale this technology and we are the only technology in the world that can do this. Our collaboration agreement with First Line puts the right people and equipment in place to do that. For this technology to save time on an offshore platform, the incremental costs and reductions would be pretty massive. We believe that we can take it offshore and provide all these benefits to those operators.”

Maureen McCall is an energy professional who writes on issues affecting the energy industry.