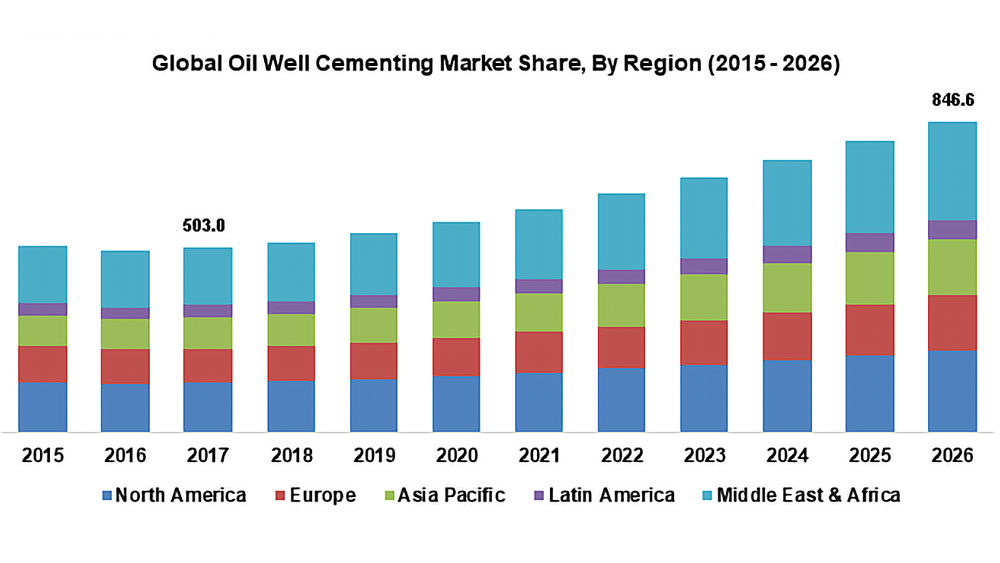

Oil Well Cementing Market Worth USD 848.6 Million by 2026

The global oil well cementing market was estimated at a worth of USD 503.0 million in 2017 and is projected to grow at a CAGR of 6.3% over the forecast period. Increasing exploration and production from unconventional oil & gas reserves, rising count of matured wells, and increasing production from offshore reserves are expected to be the major driving factors for growth of oil well cement market over the forecast period.

There are several grades of these cement products, but majorly are categorized into ordinary, moderate sulphate resistant (MSR), and high sulphate resistant (HSR). On the basis of application, the global market is further segmented into onshore and offshore. Ordinary (Grade 0) also known as normal Portland cement is one of the widely used type of Portland cement which is the most common cement type for general use as a basic ingredient of non-specialty grout, mortar, stucco, and concrete.

Moderate sulphate resistant (MSR) also called type II cement is used where precaution against moderate sulphate attack is important. MSR usually generates less heat of hydration at a slower rate than cement Type I and thus, this cement is used in mass structures such as retaining walls, large piers, and heavy abutments.

MSR are preferred in hot water due to less heat generation. High sulphate resistant (HSR) type of cement is used when concrete is exposed to highly alkaline soil or water having high sulphate content. Such cement is used where soils or ground waters have a high sulphate content as HSR is not resistant to acids and/or other highly corrosive substances.

The raw material used for manufacturing oil well cement includes limestone, iron ore, coke and iron scraps. The product is manufactured from clinkers of Portland cements and also from cements that are hydraulically blended. Oil well cements are formulated for resisting high pressures and temperatures within the wellbore.

These products set slowly owing to its organic retarders which prevent it from setting too fast. It is due to all these characteristics that it is used in the building of the oil wells where the pressure is around 20,000 PSI and the temperature is around 500 degrees Fahrenheit.

The cement slurry is pumped into the wellbore through the casing and fills the space between the wellbore and casing. Cementing plug is inserted into the casing to provide sealing and removes debris from the casing. The main service providing companies include Halliburton, Schlumberger, Trican services and Baker Hughes which are the end-use segments of the oil well cement value chain.

Onshore drilling operations segment accounted for the largest market in 2017 with a share of 67.3% of oil well cementing market in 2017. Demand from offshore oil well drilling operations are anticipated to witness significant growth and account for 32.7% share of the global oil well cementing market in in 2026. Increasing exploration & production activities from offshore oil and gas reserves are expected to be driving product demand in the present industry space. However, ongoing investments in onshore matured and old wells can be considered a consistent source of product demand from the segment.