Refineries and air quality in Romania

The European Commission (EC) referred Romania in mid-May, together with other five countries, to the Court of Justice of the European Union (CJEU), for failing to respect agreed air quality limit values. Thus, officials in Brussels sanction the repeated failures of France, Germany, the United Kingdom, Italy, Hungary and Romania “for failing to respect agreed air quality limit values and for failing to take appropriate measures to keep exceedance periods as short as possible”. In order to see what the concrete situation is and what measures have been taken or will be taken by the Ministry of Environment and the largest refineries in Romania, we have collected in this analysis official information from those involved.

Romania, Hungary and Italy are referred to the Court of Justice over persistently high levels of particulate matter (PM10), the EC claims. The limits, set out under EU legislation on ambient air quality (Directive 2008/50/EC) had to be met in 2010 and 2005 respectively, EC accuses, which mentions that, in Romania’s case, the worst situation is in the agglomeration of Bucharest, where the daily limit values have been persistently exceeded, ever since the EU law became applicable to Romania, and in 2016 on 38 days.

EC’s decision follows an additional reasoned opinion sent to Romania in September 2014, within the infringement procedure.

In Italy, in 28 air quality zones, including in the regions of Lombardy, Piedmont, Lazio and Veneto, the daily limit values have been persistently exceeded, in 2016 on up to 89 days. In Hungary, in three air quality zones, Budapest, Pecs and Sajó valley, the daily limit values have been persistently exceeded, in 2016 on up to 76 days. Also, the EC decided to refer France, Germany, and the United Kingdom to the Court of Justice of the EU for failure to respect limit values for nitrogen dioxide (NO2), and for failing to take appropriate measures to keep exceedance periods as short as possible.

In all cases of exceedance of limit values set by EU law on ambient air quality, Member States have to adopt air quality plans and ensure that such plans set appropriate measures so that the exceedance period can be kept as short as possible. Guided by the principle of subsidiarity, EU legislation gives Member States the choice of which means to use to comply with the limit values. Furthermore, the CJEU can acquit or condemn the Member States.

In the case of Romania, a possible conviction in the CJEU could cost a penalty of a lump sum plus penalties to be calculated on the basis of a specific formula, per day of delay, from the date set by the CJEU under its possible decision. In 2014, for example, the lump sum was EUR 1.8 million, with penalties between EUR 2,165 and EUR 130,000 per day of delay.

Following the release of the EC press release, the Ministry of Environment made the following remarks: “In our country, it is about the infringement procedure for exceeding the limit values for the particulate matter PM10 in the Bucharest urban agglomeration, triggered in 2009. In all cases of exceedance of limit values set by EU law on ambient air quality, Member States have to adopt air quality plans and ensure that such plans set appropriate measures so that the exceedance period can be kept as short as possible. Aware of the importance of ensuring air quality and the severity of the three existing breaches, Environment Minister Gratiela Gavrilescu considers these issues a priority for her mandate. Thus, direct meetings were held with the mayors of the three urban agglomerations for which the EC had launched infringement procedures, with a view to speeding up the adoption of air quality plans as well as with local authorities and polluters in other agglomerations. There were also three meetings with European Commissioner Karmenu Vella on this issue.

In order to reduce the impact of road traffic on air quality, the Ministry of Environment continued the RABLA and RABLA PLUS programs, allocating substantial amounts, especially for RABLA PLUS, following to promote for the same purpose other programs (electric vehicles for public transport and facilitating the transfer of a freight segment from the road to the railways etc.)

Regarding the Bucharest urban agglomeration, the local public authority has taken all the necessary steps, in accordance with the schedule agreed with the mayor of Bucharest, and managed to finalize the integrated air quality plan within the announced deadline so that it could be approved by the end July 2018 as the Bucharest Municipality has undertaken and informed the European Commission. Moreover, the Ministry of Environment has permanently communicated with the EC representatives and informed them about all the steps taken, together with the responsible authorities, to solve all the causes of the infringement, the involvement of the representatives of the Bucharest Municipality and the collaboration of the ministry specialists with them being exemplary. Although the European Commission has launched the referral procedure, we are convinced that with the approval of the Integrated Air Quality Plan by the General Council of the Capital and its immediate implementation, Romania will prevail.”

Are the refineries in Romania polluting or not?

At national level there are four facilities falling in the category of activities 1.2. Oil and gas refining from Annex no. 1 of Law 278/2013 on industrial emissions, with subsequent amendments and additions. In Romania, as in the other Member States of the European Union, carrying out in terms of environmental protection an activity subject to Law 278/2013 on industrial emissions, with subsequent amendments and additions, such as the oil and gas refining activity, can only take place if the facility holds an Integrated Environmental Permit.

Romania has requested and obtained, following negotiations with the EC, for this category of activities, a transition period starting with 2007, of five to eight years, for compliance with the European legislation in the field of environmental protection and implementing the recommendations of Best Available Techniques Reference Documents (BREFs). The transition periods are presented in Annex VII to the Treaty of Accession of Romania to the European Union (TA), ratified by Law 157/2005.

The activity of facilities in terms of environmental protection was regulated during the transition period through integrated environmental permits with Action Plans for complying with the requirements of the European environmental protection legislation. After the transition period, as a result of the investments made, these facilities have obtained a new integrated environmental permit, demonstrating through the evaluation studies that they apply the best available techniques (BAT) in the field, presented in the Best Available Techniques Reference Document (BREF) for refining mineral oil and gas. Facilities that have not complied with the provisions of European environmental protection legislation at the end of the transition period and did not put into practice the best available techniques were forced to discontinue their activity.

At present, for the oil and gas refining facilities, the competent environmental protection authority responsible for issuing the integrated environmental permit is required to take the necessary measures for the operators to implement by 28 October 2018 the new Decision (EU) 2014/738 on the establishment of the Best Available Techniques (BAT), under Directive 2010/75/EU of the European Parliament and of the Council for the refining of mineral oil and gas. For this purpose, the competent environmental protection authority responsible for issuing the integrated environmental permit is required to make sure that all conditions from the integrated environmental permit are reviewed and, if necessary, updated, in order to ensure compliance with the provisions of Law 278/2013.

Quality of life depends on air quality, but air quality is the responsibility of everyone – authorities, economic agents and citizens

Three refineries in Ploiesti. What does APM Prahova do?

Prahova Environmental Protection Agency (APM) is continuously monitoring air quality through a network consisting of six automatic stations (two traffic stations: PH1 station – APM headquarters and PH5 station – Bucharest Boulevard, two industrial stations: PH4 station – Brazi City Hall and PH6 station – Mihai Bravu Boulevard; one urban background station: PH2 station – Victoriei Square and one suburban background station: PH3 station – Blejoi City Hall) for the indicators provided by Law 104/2011 – sulphur dioxide, nitrogen oxides, ozone, carbon monoxide, particulate matter – PM10 and PM2.5 fraction, volatile organic compounds (benzene, toluene, o-xylene, ethylene benzene, m, p-xylene).

The Ministry of Environment, at the request of APM Prahova, has allocated an analyser of volatile organic compounds (benzene, toluene, o-xylene, ethylbenzene, m, p-xylene) to the PH6 automatic air quality monitoring station in the eastern area of Ploiesti (the only automated station where no such analyser was allocated) and a PAH sampler to determine the benzo (a) pyrene indicator used as a marker for the assessment of the carcinogenicity of polycyclic aromatic hydrocarbons at the PH2 – Victoriei Square automatic monitoring station.

Given the sensitive situation in Ploiesti – the existence of the refining industry, the processing of crude oil and natural gas, the storage of petroleum products at terminals, the storage and processing of waste, APM Prahova carried out indicative measurements with the laboratory on wheels and a portable pollutant analyser not regulated by Law 104/2011 regarding the ambient air quality with subsequent modifications, based on the Supplementary Monitoring Plan, which monitored the evolution of the air quality in the proximity of the major industrial platforms in Ploiesti, respectively the influence area of Vega refinery, the southern area influenced by the activity on Astra industrial platform, the eastern industrial platform area and the Petrobrazi Refinery’s influence area.

The increased values in relation to the specifics of the areas for the automatic air quality monitoring stations, as well as the overruns registered following the additional monitoring with the laboratory on wheels are transmitted by APM Prahova, the National Environmental Guard – Prahova County Commissariat, in order to take the necessary measures, in line with its competencies. All reports, information and analysis bulletins are available on the APM Prahova website at: http://apmph.anpm.ro/web/apm-prahova/calitatea-aerului. Moreover, in the procedures for issuing/reviewing integrated permits/integrated environmental permits for operators carrying out their activity in Ploiesti, APM Prahova requires additional monitoring of the pollutants specific to each type of activity, as well as self-monitoring of imissions, according to the provisions of Law 104/2011.

Romania, as a Member State of the European Union, has implemented at national level the Register of Pollutants Emitted and Transfer, in accordance with the provisions of Regulation (EC) 166/2006 of the European Parliament and of the Council concerning the establishment of a European Pollutant Release and Transfer Register and amending Council Directives 91/689/EEC and 96/61/EC (EPRTR Regulation). The EPRTR Regulation establishes a Community-wide pollutant release and transfer register (called ‘European PRTR/EPRTR’) in the form of a publicly available electronic database. The PRTR Registry includes specific information on the emissions of pollutants into air, water and soil, as well as shipments of waste and pollutants from off-site waste water, reported by operators of industrial complexes carrying out one or more of the activities listed in Annex I to the EPRTR Regulation, if the applicable capacity threshold(s) (Annex I of the EPRTR Regulation) and the emission threshold(s) (Annex II of the EPRTR Regulation) or waste threshold(s) are exceeded (2 tons for hazardous waste and 2,000 tons for non-hazardous waste).

According to the requirements of the EPRTR Regulation, Romania has created the national PRTR Registry website that allows public access both from the country and abroad to environmental information on industrial complexes in Romania by accessing the address http://prtr.anpm.ro. The European EPRTR website can be accessed at http://prtr.ec.europa.eu.

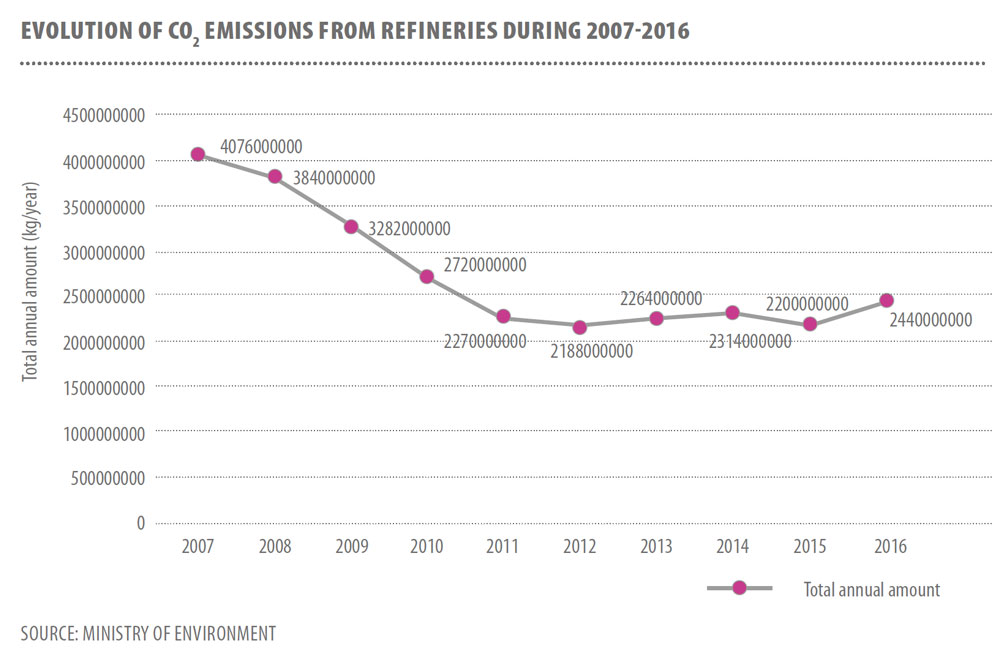

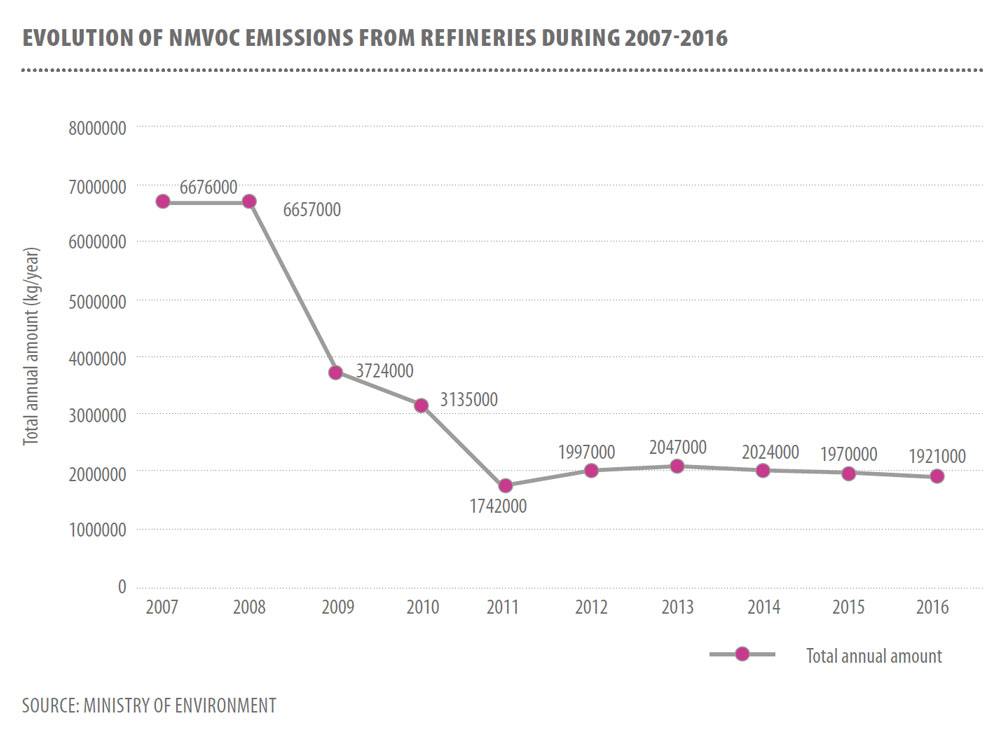

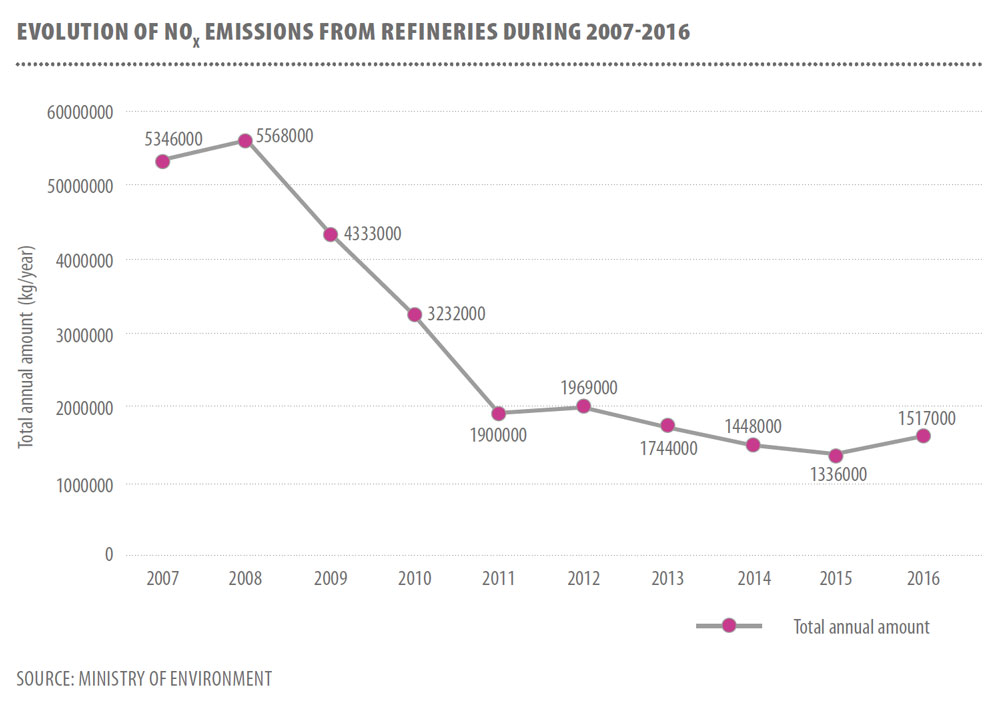

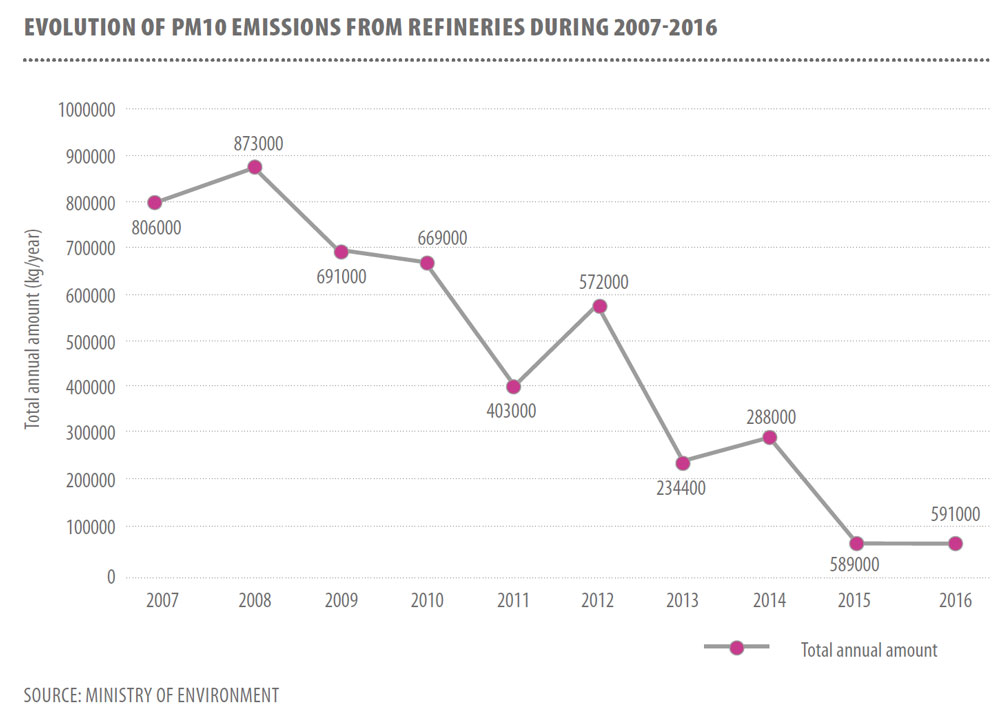

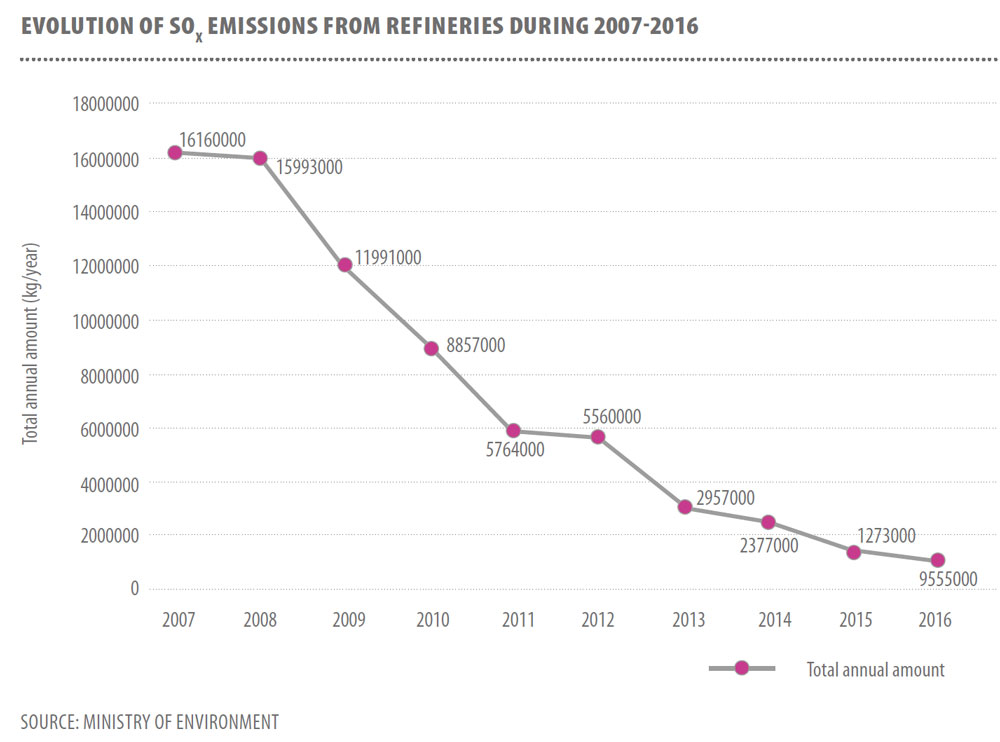

Analysing the national emissions of the main air pollutants emitted from the oil and gas refining activity at the national level during the period 2007-2016, a general trend is observed of the decrease of the pollution indicators (see the graph ‘Evolution of CO2 emissions from refineries during 2007-2016’).

First refinery to obtain the environmental permit

Rompetrol Rafinare, through the Vega Ploiesti Refinery, currently owns and operates the oldest refinery in operation in Romania, and also the only domestic producer of bitumen and hexane.

“The Ploiesti unit works in perfect synergy with the Petromidia – Navodari refinery, the largest in the country and one of the most modern in the Black Sea region. Thus, Petromidia provides to the refinery in Ploiesti the raw/semi-finished materials needed to obtain special products with high added value,” says the Department of Communication and Public Relations of the KMG International Group.

On 5 January 1905, the Board of Directors of Vega Societatea Anonima Romana (S.A.R.), chaired by Titu Maiorescu (Foreign Minister between 1910 and 1914 and Prime Minister of Romania from 1912 to 1913) decided to build a refinery in the northern part of Ploiesti near the future Ploiesti-Nord train station of Ploiesti – Valenii de Munte line. The design of the refinery took into account the conformation of the land, and the arrangement of the oil tanks and the processing facilities followed the use of the ‘natural fall’ principle. The construction works started in May 1905 on a land of about 50.4 hectares, and on 18 November of the same year the commissioning of the oil processing plants started. In the first phase, the supply of raw materials was carried out with carriages, then with tank wagons and finally by the construction and connection of the tanks to three pipelines – one in the Bustenari – Recea area and two in the Moreni region, connected with Baicoi.

Among the innovations made within the refinery are the development, in 1908, of Eng. Lazar Edeleanu, PhD, (director of the refinery during 1906-1913), of a unique oil processing method, by selective refining of petroleum fractions on the basis of the specific solubility of various grades of hydrocarbons in liquid sulphur dioxide, which allows selective extraction of aromatic hydrocarbons (benzene, toluene, xylene etc.). The method was patented in Romania (1908), USA (1909) and Austro-Hungary (1910). In 1960, approximately 80 ‘Edeleanu plants’ were estimated in different countries of the world.

Vega Ploiesti Refinery became a joint stock company in 1990, and in 1997 – against the background of the difficult economic situation, the company was on the list of the 16 companies proposed for liquidation for eight months. The majority shareholding of the Ploiesti-based refinery was taken over in May 1999 by the Rompetrol Group (currently, KMG International), based on a privatization contract concluded with the State Property Fund (FPS).

With the acquisition and integration of the Petromidia Navodari refinery in the activities of the Rompetrol Group in October 2000, the development strategy of the Vega Ploiesti Refinery aimed at transforming it from a classic refinery into a producer and supplier of special products and solutions (organic solvents, special-purpose bitumen, ecological heating fuels, other dedicated products – white spirit, n-hexane etc.).

The investments made since 1999 to date in order to consolidate and expand the profile activities of the Vega refinery amounted to about USD 61 million and aimed at the modernization of the production units, the development of the product range (a new bitumen plant was built in 2007) reducing and eliminating environmental impact, and also increasing safety in the operation of equipment.

“Vega Ploiesti Refinery was the first unit in Romania to receive the integrated environmental permit in 2006, a regulatory act with continuous certification that the Vega refinery’s activities are in line with the European standards for integrated pollution prevention and control. Between 2000 and 2006, an amount of approximately USD 15 million was allocated to comply with environmental compliance and management programs, out of a total investment over the same period exceeding USD 31 million. Another important project for Vega refinery was and continues to be the greening of acidic tars and oil residues pits that were overwhelmingly deposited in the period prior to the privatization of Vega Ploiesti (1905-1999). According to the documents in the refinery’s privatization dossier, the amount of waste that the future shareholder was going to take for greening was estimated at approx. 62,000 tons. After the completion of the privatization procedure, it was found that the total volume of waste in the pits was at least 4 times higher. In the period 2002-2011, a total quantity of about 80,000 tons of waste from acid tars and petroleum residues pits was eliminated through authorized economic operators, well above the level brought to the attention of the company in the privatization process. The costs of these operations amounted to about USD 17.4 million. The company currently carries out an extensive process of selection of a company with experience in the field, in order to achieve the decontamination and complete greening of the pits at the Vega Ploiesti Refinery. The implementation of the pits rehabilitation project involves not only the allocation of extraordinary financial resources, but also the careful and responsible selection of the available technologies, the most rigorous safety measures and the permanent cooperation with the competent environmental authorities,” the Department of Communication and Public Relations of the KMG International Group also mentions.

The removal of historical acid tars is not the only environment investment in progress for the Vega refinery. At present, KMG International has in progress investments of over USD 10 million to keep the Vega refinery at the highest quality and environmental standards for the safety of its employees and of the Ploiesti city. One of these investments, worth USD 1.7 million, is the new steam boiler, which will provide the necessary steam for technological operations in the refinery, under the conditions imposed by the legislation in force.

Another important project is the recovery of hydrocarbon vapours at petroleum product loading points and the mounting of membranes for tanks storing volatile products. The project will involve replacing the current system and recovering all volatile hydrocarbon vapours that occur during the load of refinery products in tanker trucks. This will have a strong positive impact on air quality but also on technological loss cuts. Also, an important project in the phase of the technical solution study is the installation of an incinerator for the technological gases from Bitumen, Vacuum Distillation and De-aromatization plants. This equipment will improve the refinery’s technological flow, allowing controlled combustion of non-condensable gases.

“Rompetrol Rafinare – Vega Ploiesti Refinery is carrying out its activities in compliance with the national and international environmental standards, and also with the legislation in force. Although it is no longer processing crude oil or obtaining automotive fuel, Vega Refinery recorded a total quantity of 373,000 tons of processed raw material in 2017, registering record production of bitumen (96,400 tons) and ecological solvents (41,000 tons). The total quantity of raw material processed by Vega Ploiesti Refinery in the period 1906-2017 amounts to about 68 million tons, with a maximum of 1.13 million tons achieved in 1979 – the commissioning of Petromidia Navodari Refinery,” the representatives of Rompetrol also mentioned.

Environmental permit until 2023 for the largest refinery in Romania

Rompetrol Rafinare – Petromidia Navodari Refinery is currently the largest profile unit in Romania, with a volume of raw materials processed in 2017 of 5.66 million tons (16,800 tons per day), being at the same time one of the most modern in the Black Sea region (Nelson complexity index – 10.5). The investments made by the Group since 2000 – the moment of takeover, to date have focused on the development of the activities of the companies present on the Petromidia platform, under conditions of maximum technological efficiency and environmental protection.

“It is a responsibility and moral duty for both the companies and Rompetrol employees to protect the Black Sea and Siutghiol Lake, the Danube Delta biosphere and the Midia Channel ecosystem, as well as the Navodari, Corbu and Constanta localities,” Rompetrol representatives also claim.

At the end of 2012, the company successfully completed the transition period granted to Petromidia Refinery to align the facilities to the European environmental requirements, i.e. compliance with the BAT/BREF requirements (Best Available Techniques for Refining). Thus, all the projects under the action plan, part of the integrated environmental permit, have been completed.

Petromidia became in 2013 the country’s first refinery holding the new integrated environmental permit valid for 10 years, with no compliance program. The document certifies that the operation of facilities on Petromidia platform is in accordance with the highest performance and environmental standards, while setting the conditions and parameters of the activities (air, water and soil emissions, waste management measures).

Petrotel-Lukoil, investments in two major environmental projects

The Prahova Chamber of Commerce and Industry hosted on 29 March a public dialogue organized by Petrotel-Lukoil Ploiesti, through which Gleb Ovsyannikov, the head of the Public Relations Department of the Russian company, presented the actions of social responsibility, and also its plans for the future. The company’s representatives have proposed to have meetings with representatives of public authorities to find out from them what are the projects of major interest in which the refinery might be involved, this meeting being the first of its kind.

“We are one of the largest taxpayers in Russia, and in the countries where we operate, we are an important employer and a social partner. Petrotel-Lukoil is one of our best refineries in Europe, if not even the best. Concern for our employees is part of social responsibility, an area in which, in each of the past two years, we have invested USD 177mln,” the Russian official has stated. He proposed that such events take place twice a year in the form of round table meetings, where participants will present the projects they want to develop for the local community.

“The Petrotel-Lukoil Ploiesti refinery has proven over time that it is interested in investing in environmental protection and social projects. On this occasion, I welcome the involvement of the refinery’s management in programs like afforestation on the East Ring of Ploiesti, where everyone can see that seedlings planted five years ago have become a young and strong forest, and setting up several playgrounds for children in Ploiesti. At the same time, the support that the refinery constantly gives to the Petroleum-Gas University to carry out its research programs cannot be overlooked,” the Prahova County Prefect, Madalina Lupea, has mentioned.

Petrotel S.A. refinery was taken over by Lukoil Group in 1998. At the time, the facilities of the refinery were partially obsolete and did not comply with the environmental legislation. Therefore, an extensive investment program was started, in both technological and environmental objectives undertaken upon privatization. Since 1998 and until 2005, approximately USD 11 million have been invested in environmental protection works, ending with a reduction of about 35% in sulphur dioxide emissions and about 20% in volatile organic compounds. In 2007, the refinery received the Integrated Environmental Permit and with it the Action Plan for compliance with the national and European requirements. From 2008, a new investment stage started, in order to carry out all measures included in the Action Plan. The investment made by Lukoil in this direction amounted to USD 120 million.

Starting with 2011, the ‘LowNox’ combustion system has reduced the emissions of nitrogen oxides in the stacks of technological furnaces by approximately 70% and the powder concentration has decreased by about 8 times. In 2012, by completing the refinery gas scrubbing plant, the concentration of sulphur dioxide in the gases exhausted in the atmosphere decreased by 90 times! In early 2015, Petrotel-Lukoil completed the last investment project within the Action Plan, commissioning the flue gas scrubber plant (Belco), from the Fluid Catalytic Cracking complex. The performances achieved were remarkable: emissions of sulphur oxides dropped 30 times, and those of powders 15 times.

At this time, the refinery meets the requirements of the BREF documents and the Decision 2013/84/EU establishing best available techniques (BAT) conclusions, but according to the Directive 2010/75/EU of the European Parliament environmental investments do not stop here. In addition to the current re-equipment (mounting double sealing of dynamic equipment, continuation of double sealing or internal membrane tanks etc.), the refinery aims to invest in two major projects that will have a positive impact on the ambient air: the modernization of the Coking plant – Stage I (USD 7 million), a project that will reduce to zero process emissions (completion deadline: 2020) and the construction of a new sulphur recovery complex (USD 25.9 million) that will substantially reduce accidental emissions of sulphur oxides in the event of technical incidents or damage (deadline for completion: Q1/2020).

Investments of EUR 1.5 billion during 2005-2017 at Petrobrazi

Petrobrazi Refinery, with a refining capacity of 4.5 million tons of crude oil per year, is one of the most important units of this type in the country. Petrobrazi’s production can cover the annual demand for fuels for 3 million vehicles.

Although it was built more than 80 years ago, Petrobrazi Refinery works in line with the best performance standards, including in the environmental area, thanks to investments in recent years.

During 2005-2017, OMV Petrom has invested in Petrobrazi over EUR 1.5 billion. There have been dedicated environmental projects, but also other projects to upgrade or build new facilities that have directly contributed to reducing the environmental impact.

“These investments have allowed refinery activities to be more environmentally friendly. Specific CO2 emissions (expressed per ton of processed oil) decreased by 48% in 2017 as compared to 2004, the cumulative reduction being around 580,000 tons of CO2 during 2004-2017. The limit value for sulphur dioxide emissions dropped from 10,000 to 500 mg/Ncm, following modernization works. Also, the limit value for particulate matter emissions from the Fluid Catalytic Cracking Plant (FCC) dropped from 140 to 50 mg/Ncm following upgrading and mounting of electro filters,” says Adrian Mincu, Petrobrazi Managing Director, Downstream Oil Division.

The investments dedicated to environmental projects include:

- Modernization of the flare system, in order to eliminate the leakage of hydrogen sulphide gas;

- Greening work of the pits; more than 180,000 tons of sludge were processed there;

- Upgrading the wastewater treatment plant;

- Reducing emissions from combustion processes;

- Modernization of tanks to reduce leakage risks and reduce emissions of volatile compounds.

Other projects to upgrade or build new facilities within the refinery have directly contributed to reducing the environmental impact:

- Modernization of the gas desulphurization – sulphur recovery plant, completed in 2013. This plant is needed to produce fuels at European quality standards. But there is also a significant impact on the environment: sulphur emissions have been reduced from 10,000 to less than 500 mg/Ncm. The plant provides 99.99% sulphur recovery;

- Upgrading the FCC plant during the 2012 and 2014 overhauls. The plant provides separation of fuels (diesel and gasoline) from other crude oil components. The investments in this unit were mainly aimed at improving the depth of oil refining, but modernization also brought environmental benefits: particle emissions were reduced by the installation of electro filters, hot processing technologies of raw material were implemented, which allow reduction of environmental impact by reducing own consumption;

- Upgrading the coking plant during the 2014 and 2016 overhauls. The coking plant is an end point in the refining process. The residue from the other facilities reach here and the latest oil transformation processes are carried out here in order to obtain products used in the industry, such as coke, heavy oils or naphtha. Investments in the coking plant were aimed at replacing columns, upgrading pressure vessels etc., thus contributing to reducing emissions and improving energy efficiency;

- Modernization of the vacuum distillation plant (VDP) in the 2012 and 2014 upgrades. This plant is among the most important in a refinery. This is where the first stage of crude oil refining takes place: heavy compounds (fuel oil, bitumen) are separated from the light ones, from which gasoline, diesel and LPG will subsequently be obtained. Following the modernization process, energy consumption has been reduced and the ability to extract commercially valuable compounds from crude oil has also increased.

With regard to future plans, OMV Petrom has stated its commitment to continue investing in Romania. The Group’s strategy provides for investments of EUR 5 billion during 2017-2021, part of which is dedicated to the Downstream segment.

“One of the directions is to assess the potential of petrochemistry, but for the moment we are in an early stage of analysing the opportunities. We will come back once we have identified and approved projects in this direction. In the short term, within the Petrobrazi Refinery, we have a project to build a new Polyfuel unit. We remain committed to implementing the projects to the latest international standards, ” Adrian Mincu concluded.

Conclusions

Even if Romania received a serious and concrete warning from Brussels on air quality, it is encouraging that refineries are not primarily responsible for this negative aspect. It remains that the investments planned by them be put into practice to ensure that this vital sector of the national economy will not suffer.