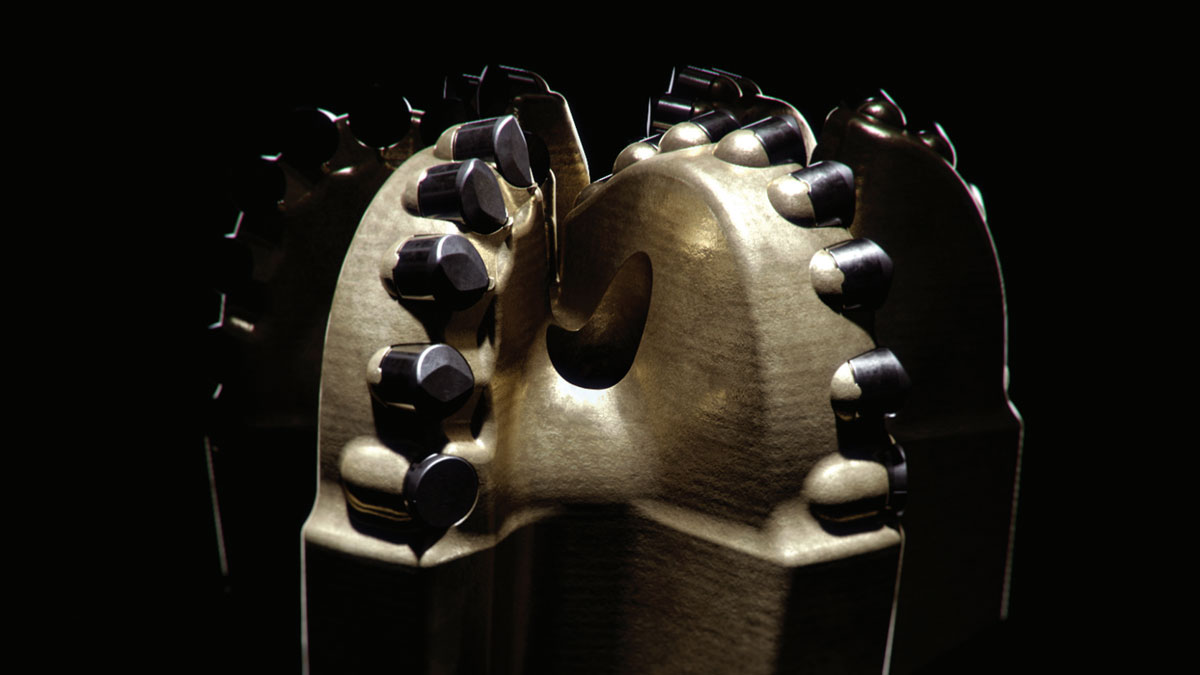

StrataBlade Concave Diamond Element Bit to Reduce Drilling Costs and Improve Performance

Smith Bits, a Schlumberger company, just introduced the StrataBlade concave diamond element bit that improves the rate of penetration (ROP) in a wide range of rock types, while withstanding impact damage often associated with drilling interbedded formations.

“The StrataBlade bit is the latest addition to our three-dimensional cutting elements portfolio, which expands our holistic drilling solutions offering and enables operators to enhance overall drilling performance in challenging formations,” said Jesus Lamas, president, Well Construction, Schlumberger. “With the introduction of this new technology operators can improve ROP, increase overall drilling efficiency and reduce well construction costs.”

The StrataBlade bit incorporates new geometry Strata concave diamond elements across the bit face, which increases cutting efficiency and results in higher instantaneous ROP with the same operating parameters. In deep lateral wells where weight transfer to the bit is a challenge, the StrataBlade bit drills with higher ROP when compared with traditional PDC bits with flat cutters. Improved cutting efficiency also means a better torque response at the bit for conformance to directional plans.

The StrataBlade bit has undergone field testing in North America, specifically in the Haynesville Shale and the Appalachian Basin. In the East Texas Travis Peak and Cotton Valley formations, the StrataBlade bit enabled an operator to eliminate two bit runs while drilling to 10,000-ft measured depth with an average ROP increase of 28% compared to direct offset wells. In the Marcellus Formation in northeastern Pennsylvania, the StrataBlade bit drilled an 8 ¾-in section with a measured depth of 3,149 ft in under 12 drilling hours. The operator achieved an on-bottom ROP of 264 ft/h, resulting in a 15% improvement compared with average offset runs with other PDC bits.

Increased cutting efficiency for instant ROP improvement

The StrataBlade concave diamond element bit saves rig time and costs by delivering faster instantaneous ROP. It withstands impact damage in interbedded drilling through medium-strength formations with unconfined compressive strengths (UCS), ranging from 5,000 to 20,000 psi [35 to 140 MPa].