Strohm’s TCP Installed on Giant Liza Field

Strohm’s first deep-water/high pressure thermoplastic composite pipe (TCP) Jumper in South America has been successfully installed, commissioned and is up and running for ExxonMobil Guyana at its Liza field.

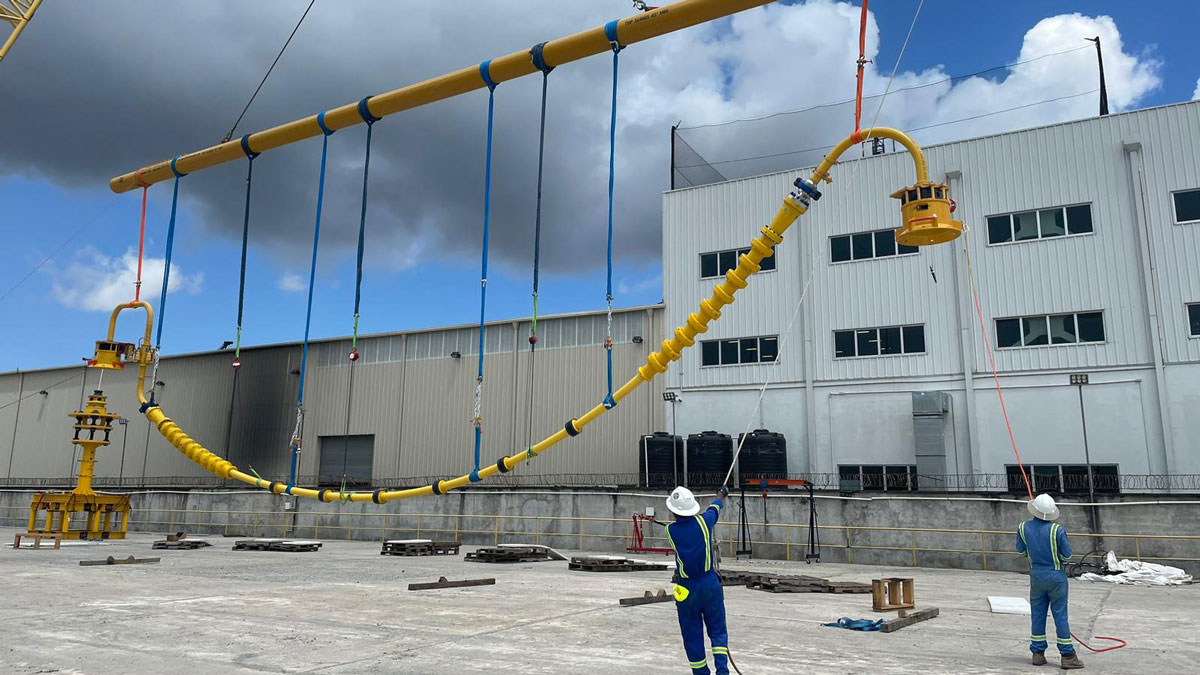

The Jumper, incorporating advanced carbon fiber and polyamide12 materials, is used for Water Alternating Gas (WAG) injection and was installed in depths over 1,700m for the supermajor, after being landed and leak tested subsea.

Previously, the Netherlands headquartered business was awarded two significant contracts for the Uaru and Yellowtail developments, where Strohm is to supply a total of 50 of its WAG TCP Jumpers across the two campaigns. These projects are delivered under the firm’s Jumpers on Demand approach, where a single length of pipe is delivered on a single reel to the client’s location, thereupon the pipe is spooled off to the desired jumper length, cut, terminated, tested, and mated with a connector system.

Strohm’s newly created Field Service Group has also recently secured the service contract to support onsite termination operations in-country and deliver on the termination scopes of work for pre-first oil for Yellowtail.

“This is a pivotal moment for our business, underlining the clear advantages that our Jumper on Demand brings to a project of this scale and depth, as well as proving our WAG application for this region. Our approach minimises transportation cost, maximises local content, and reduces the total cost of installation as well as lowering carbon footprint. This approach is proving extremely successful with multiple projects ongoing and completed around the globe. Strohm’s specialist field service technicians mobilise to the client’s location as the jumper termination campaigns are called off over the duration of the deployment programme,” Gavin Leiper, Strom’s vice president Americas and leader of the Field Service Group, said.

Strohm’s TCP Jumper avoids the need for metrology, thereby shortening time to first oil and reducing installation cost further. The flexibility to terminate in country, creates redundancy and de-risks any project schedule.

Strohm is the leading manufacturer of TCP with the largest track record in the world. It provides a strong, corrosion free and field-proven solution for operators. The use of TCP manufactured by Strohm also provides clients with the ability to significantly reduce the CO2 footprint of their pipeline infrastructure.

In addition to the 50 pipes being produced for ExxonMobil Guyana, Strohm’s Jumper on Demand service has delivered 25 of the firm’s TCP solutions installed in Europe, Brazil and Asia.

About Strohm

Leading composite pipe technology company Strohm has the world’s largest track-record for Thermoplastic Composite Pipe (TCP) after being the first to bring the new application to the oil and gas industry in 2007. TCP reduces total installed and life cycle cost for subsea flowlines, jumpers and risers and has proven to reduce the CO2 footprint of pipeline infrastructures by more than 50%.

The company is committed to driving sustainability with its range of TCP solutions which enable clients towards their net-zero carbon emissions targets and supports the renewables sector.

TCP is a strong, non-corrosive, spoolable, lightweight solution which is delivered in long lengths, resulting in a significant reduction of transportation and installation costs. TCP is installed using small vessels or subsea pallets, significantly reducing CO2 emissions. It is also 100% recyclable.

Strohm’s shareholders include Aker Solutions, Chevron Technology Ventures, Evonik Venture Capital, Saudi Aramco Energy Ventures, Shell Ventures, Subsea 7, Sumitomo Corporation, HPE Growth, HydrogenOne Capital Growth, and ING Corporate Investments (a 100% subsidiary of ING Bank N.V.).

The firm’s manufacturing facility is located at its headquarters in IJmuiden in The Netherlands. Strohm also has offices in Houston (US) and Rio de Janeiro (Brazil).