One of the First Large-scale H2 Projects in UK: H2H Saltend

Department for Business, Energy, and Industrial Strategy (BEIS) announced that Equinor’s Hydrogen to Humber Saltend (H2H Saltend) production facility has been successfully progressed through Phase-2 of the Government’s cluster sequencing process.

The selected projects will now proceed to the due diligence stage of the Phase-2 cluster sequencing process to allow them to connect to the East Coast Cluster’s CO2 infrastructure and be operational in the mid-2020s.

Previously in Phase-1 of the cluster sequencing process, the East Coast Cluster, which connects the Humber and Teesside via CO2 transport and storage infrastructure, was selected to become one of the first two ‘CCUS clusters’ in the UK.

Equinor’s bids for two new gas-fired power stations with carbon capture at Keadby, developed with SSE Thermal, and in Teesside, developed in partnership with bp, have also been successful.

“Fantastic news that the UK Government has selected three of our pioneering CCS and hydrogen projects. They will help decarbonise vital and carbon-intensive industries, preserve existing jobs and create new ones, as well as provide local supply chain opportunities. We’re excited to continue working closely with the UK Government, our partners, and local stakeholders to deliver these large-scale projects. This further strengthens the UK’s position as a world leader in the energy transition,” Grete Tveit, senior vice president for Low Carbon Solutions, Equinor, said.

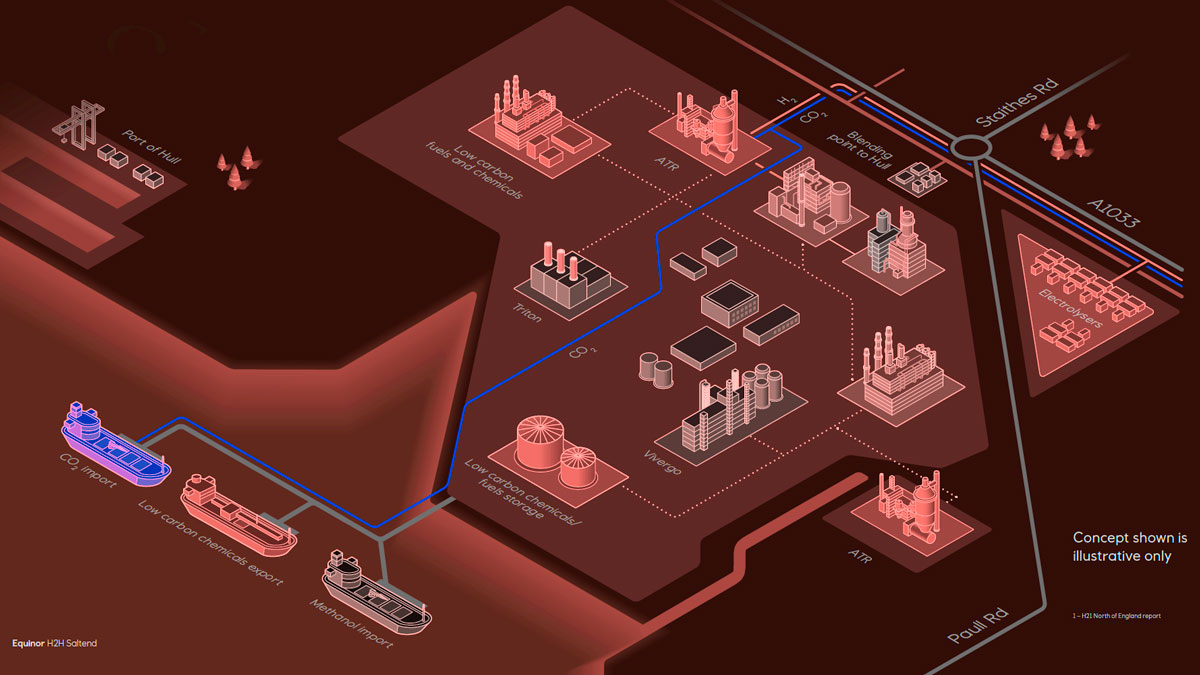

H2H Saltend is Equinor’s flagship project with a 600-megawatt low carbon hydrogen production plant, located at the Saltend Chemicals Park (SCP), to the east of Hull.

The Humber is the most carbon intensive industrial region in the UK and H2H Saltend could enable a variety of critical industries at SCP and the wider East Yorkshire area to reduce CO2 emissions by nearly one million tonnes annually.

The projects that are finally selected will start operations in 2026/2027.

H2H Saltend is the kick-starter project for the wider Zero Carbon Humber scheme, a UKRI-supported partnership of 14 organisations committed to making the Humber the world’s first net zero industrial cluster by 2040.

Equinor is also planning a second 1.2-gigawatt low carbon hydrogen production facility in the Humber which combined with H2H Saltend could deliver 18% of the UK Government’s target of 10GW hydrogen production capacity by 2030.

In partnership with SSE Thermal, Equinor is also planning to develop the world’s first at-scale 100% hydrogen power station at Keadby and a proposed hydrogen storage facility at Aldbrough.

Cluster Sequencing Process

The UK Government’s Ten-point plan for a green industrial revolution set out an ambition to deploy CCUS at scale in two of the UK’s industrial clusters by the mid-2020s, and a further two by 2030 in order to help the UK meet the net zero and Carbon Budget 6 targets.

Phase-1 of the Cluster Sequencing Process identified and sequenced CCUS clusters which are suited to deployment in the mid-2020s (known as Track-1). Last year, the East Coast Cluster and HyNet were announced as Track-1 clusters, and the Scottish Cluster as a reserve cluster if a back-up is needed.

Phase-2 was open to power, industrial carbon capture and hydrogen production projects which had an interest in accessing Track-1 clusters and met the technology specific eligibility criteria. Phase-2 concluded following project shortlisting and the announcement of projects that will enter negotiations for possible support.

About Equinor’s selected projects

H2H Saltend

The Equinor-led 600-megawatt Hydrogen to Humber (H2H) Saltend project could be one of the UK’s – and the world’s – first at-scale facilities to produce hydrogen from natural gas in combination with carbon capture and storage (CCS). The project will enable fuel switching in 2026-2027 resulting in a CO2 emissions reduction of 900,000 tonnes per year.

Keadby 3 Carbon Capture Power Station

Keadby 3 Carbon Capture Power Station, developed in partnership with SSE Thermal, could be the world’s first commercial scale gas-fired power station with carbon capture, with an electrical output of up to 910 megawatts.

NZT Power

Net Zero Teesside Power (NZT Power), developed with bp, is a proposed gas-fired power station with carbon capture. NZT Power’s proposed power station will have an electrical output of up to 860 megawatts of low carbon electricity.