CorPower Ocean’s First Commercial Scale C4 WEC

CorPower Ocean has partnered with subsea composite specialist Diab for the construction of its first commercial scale Wave Energy Converter (WEC).

The ocean energy developer is currently fabricating its next generation C4 WEC, with dual build-out operations in Sweden and Portugal.

Part of the flagship HiWave-5 Project, the WEC will ultimately join a four-system wave energy array, located off the coast of Aguçadoura in Portugal, forming one of the world’s first grid-connected wave farms.

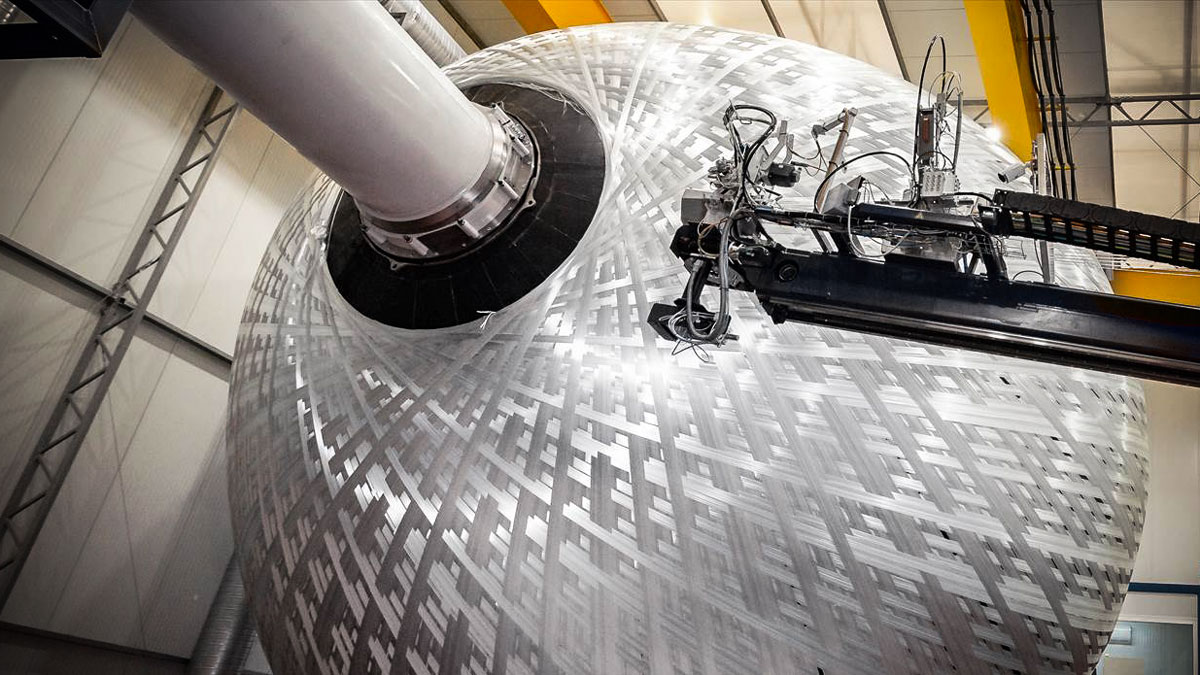

Following several months of process characterization on ¼ scale models, CorPower Ocean is now nearing completion of the first commercial scale hull at its Portuguese base in Viana do Castelo.

The site is also demonstrating the firm’s ‘mobile factory’ concept designed to enable rapid roll-out of WEC hulls in port facilities near wave energy sites across the globe.

A key element to the hull’s sandwich structure involves the core material which provides strength and stiffness. Produced by Swedish firm Diab, the unique Divinycell H grade material brings a raft of benefits including high strength, durability and impact resistance combined with light weight and buoyancy performance properties.

“Diab’s technology is an ideal match for our composite hull structure, meeting all requirements with relevant certifications,” said CorPower Portugal Managing Director Miguel Silva. “The Divinycell H sandwich composite is particularly well suited to WEC devices being designed specifically to withstand major fatigue, slamming and impact loads. Other important features include excellent adhesion strength and chemical resistance, with low water absorption and strong thermal insulation.”

Diab has been supporting the development of subsea applications for more than 50-years including high demand structural and buoyancy solutions for civil and defence sectors.

During its latest partnership with CorPower Ocean, Diab provided structural engineering support, including analysis of loads and stresses exposed to the hull, to ensure the correct selection of core materials and laminates for the composite structure.

Diab Segment Manager Lars-Magnus Efraimsson said Divinycell H has a proven track record in virtually every application area where sandwich composites are employed, including the marine, land transportation, wind energy, civil engineering, and general industrial markets.

“We are pleased to be expanding our portfolio in the subsea sector working with a fellow Swedish outfit and one of the leading wave energy developers,” he said. “It’s always a pleasure to work with firms like CorPower Ocean which share our passion for innovation, as we continually explore new ways to improve our offering and make our clients’ products stronger, lighter and smarter.”

CorPower’s HiWave-5 Project

CorPower’s HiWave-5 Project continues in northern Portugal following a decade of product development and three decades of research on wave hydrodynamics. The Swedish-headquartered developer is currently fabricating its first commercial scale C4 WEC. Dry testing in Sweden was initiated the first part of 2021, in preparation for ocean installation at the Aguçadoura site in Portugal in Q2 2022. This will be followed by three additional CorPower C5 machines in 2023 to form a pilot array and secure type certification.

A 10-year marine license (TUPEM) has been secured for the use of the Aguçadoura site located offshore south of CorPower’s facilities in Viana do Castelo.

Product verification process

CorPower follows a structured five-stage product verification program recognized as best practice in the sector. It includes verifying step-by-step that the business case is supported by the physical and economical metrics in each stage starting with small scale prototypes in Stage 1 to full scale array demonstration in Stage 5. Dry testing in controlled simulated wave loading on-land to debug and stabilize the machines prior to ocean deployment is a key part of the strategy. It includes a rigorous Certification process with DNV-GL and independent validation of device performance by EMEC and WavEC.

What Makes CorPower technology unique?

The CorPower Wave Energy Converter (WEC) produces 5 times more electricity per ton (>10MWh/t) than any other known wave technology by combining: a. storm survivability and b. strongly amplified power capture in regular sea conditions.

CorPower WECs can harvest the same amount of Annual Energy from a buoy with 1/10 volume compared to conventional point absorber WEC. As comparison, a 300kW CorPower WEC has a diameter of 9m and weighs 60 tonnes. Getting large amounts of electricity from a small device significantly reduces CAPEX. The compact lightweight devices are also less costly to transport, install and service, bringing down OPEX.