WindH2: Salzgitter, E.ON and Linde to Produce Green Hydrogen

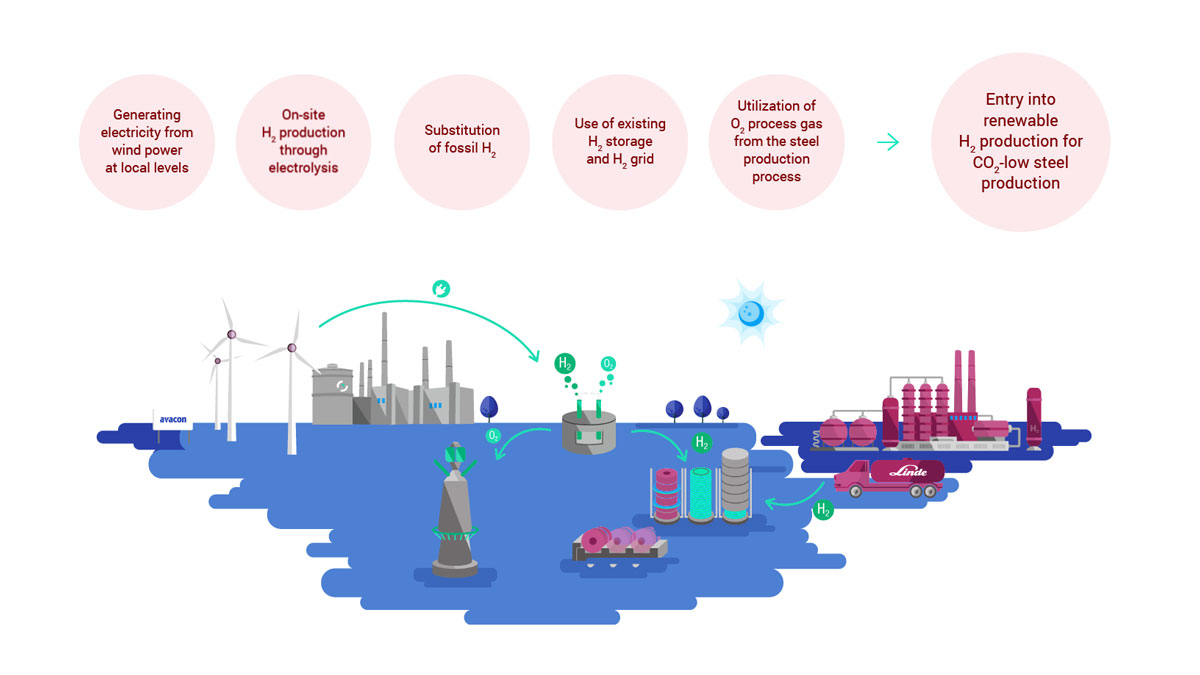

With the commissioning of the ‘Wind Hydrogen Salzgitter – WindH2’ sector coupling project, the only one of its kind in Germany, green hydrogen will in future be produced on the site of the Salzgitter steelworks using electricity from wind energy.

The three project partners Salzgitter, E.ON subsidiary Avacon and Linde have taken an important and unprecedented step towards decarbonizing the steel industry.

WindH2 is a central component of the SALCOS® – Salzgitter Low CO2 Steelmaking technology project developed by Salzgitter AG. SALCOS describes the most efficient and timely way to reduce CO2 emissions, and in the long term even to achieve almost CO2-free steel production. Hydrogen generated from renewable sources will replace the carbon previously required for iron ore smelting. The three blast furnaces currently in operation will have to be gradually replaced by a combination of direct reduction plants and electric arc furnaces. Such a transformation of steel production could reduce CO2 emissions by around 95 percent by 2050.

The newly constructed facilities were presented to the public on March 11, in Salzgitter. Among those present at the opening were State Secretary Andreas Feicht, Federal Ministry for Economic Affairs and Energy; Dr. Bernd Althusmann, Lower Saxony Minister for Economic Affairs, Labor, Transport and Digital Affairs; Olaf Lies, Lower Saxony Minister for the Environment, Energy, Building and Climate Protection; Dr. Johannes Teyssen, CEO of E.ON SE; Marten Bunnemann, CEO of Avacon AG, and Prof. Dr.-Ing. Heinz Jörg Fuhrmann, CEO of Salzgitter AG.

“The ‘Windwasserstoff Salzgitter – WindH2’ project was supported by the Federal Ministry for Economic Affairs and Energy with 1.1 million euros from the federal funding for energy efficiency in the economy. With the sector coupling of wind energy and hydrogen production, the project implements one of the objectives of the German government’s National Hydrogen Strategy: The use of climate-friendly hydrogen produced from renewable energies is a key element for decarbonization in industry,” Federal Ministry for Economic Affairs and Energy stated.

“What many thought was a wild vision of the future a few years ago is happening here: the gradual decarbonization of steel production. Climate protection in the energy and industrial sector is much more than just electricity from renewable sources. This is about securing highly skilled jobs and further developing our industrial base. As the cost of CO2 rises, green steel will also become increasingly economical. The world is therefore watching with interest to see what is being created here. The pioneering work done here has every chance of becoming a ‘Made in Germany’ export hit,” Olaf Lies, Lower Saxony Minister for the Environment, Energy, Building and Climate Protection, underlined.

Prof. Dr.-Ing. Heinz Jörg Fuhrmann, Chairman of the Executive Board of Salzgitter AG added: “We are proud to be pioneers in the industrial use of green hydrogen in the steel industry. As demonstrated by our SALCOS project, we are technologically capable of achieving significant CO2 reductions using hydrogen. The ‘Wind Hydrogen Salzgitter- WindH2’ sector coupling, which is unique in Germany to date, is a significant building block on the way to climate-friendly steel production.”

Avacon operates seven newly constructed wind turbines with a total capacity of 30 megawatts on the Salzgitter AG site. Salzgitter Flachstahl GmbH has installed two Siemens 1.25-megawatt PEM electrolysis units centrally on the plant site, which will generate around 450 cubic meters of high-purity hydrogen per hour. Hydrogen is already used in steel production for annealing processes and in the hot-dip galvanizing lines. Industrial gas producer Linde currently supplies the gas by truck and will continue to ensure a continuous supply of hydrogen in the future. All the plants are currently in trial operation. With WindH2, the partners want to gain know-how and experience with the on-site production of wind power and hydrogen, as well as their integration into the complex procedures and processes of an integrated steelworks.

The costs for the entire project amount to around 50 million euros. The construction of the electrolysis plant was funded by KfW.

“Green gases have what it takes to become the ‘staple’ of the energy transition and make a significant contribution to decarbonizing industry mobility and heat. The jointly implemented project symbolizes a milestone on the way to virtually CO2-free steel production and shows that intelligent sector coupling can replace fossil fuels,” Dr. Johannes Teyssen, CEO of E.ON SE, mentioned.

“In view of the climate targets, the decarbonization of steel production with the aid of green hydrogen is a milestone for the German steel industry. I am pleased that Lower Saxony, through Salzgitter AG, is pioneering this development nationwide and is launching a promising project with WindH2. With its pioneering work, Salzgitter is providing the blueprint for future climate-friendly production technologies at the German industrial site and at the same time securing qualified jobs in Lower Saxony,” Dr. Bernd Althusmann, Lower Saxony’s Minister for Economic Affairs, Labor, Transport and Digital Affairs, pointed out.

“With the wind farm on the industrial site of Salzgitter AG, we are supplying renewable electricity for the production of green hydrogen. This is used directly within the production processes and replaces fossil fuels. The entry into the hydrogen economy is emerging in regional stand-alone solutions, such as in Salzgitter, which are increasingly being combined to form an overall system. We will continue to drive this process forward together with our partners in politics, science and industry,” Marten Bunnemann, CEO of Avacon AG, said.

About the project

The aim of the ‘Salzgitter Hydrogen’ sector-interconnection project is to generate hydrogen in Salzgitter through electrolysis and electricity from wind power. These activities are intended to put down the foundation for harnessing larger volumes of hydrogen in the future to reduce direct CO2 emissions in the production of steel. Avacon builded seven wind turbines with an output of 30 megawatts on the premises of the Salzgitter Group, three of which are located on the grounds of the steel mill. Industrial gas supplier Linde ensures the steady supply of hydrogen. Within the context of this project, the partners are aiming to build up know-how for the environmentally compatible production of hydrogen, as well as for gaining experience with the on-site production of hydrogen and its incorporation into an integrated steel mill with its complex production processes. Hydrogen delivered by Linde is already used today in the annealing processes that are part of producing steel. In addition, the use of hydrogen in mills opens up potential for significantly reducing the CO2 emissions generated from steel production processes in the future.

With a view to achieving this goal, Salzgitter AG conceived the SALCOS® (Salzgitter Low CO2 Steelmaking) project that maps a realistic path toward the gradual reduction of CO2 and, in the long term, steel production that is virtually free of CO2. As part of this project, hydrogen generated from renewable energies is to replace the carbon so far required for the smelting of iron ore.

Salzgitter Flachstahl is endeavoring to gain operational experience through this project in the area of generating “hydrogen from renewable energies” that is so important for SALCOS®. Subsequently, this experience could be drawn on for the implementation on an industrial scale. Although the framework conditions prevailing today do not permit the commercial operation of a direct combination of wind energy generation and electrolysis operations without government funding, the three partners are determined to develop and advance this technology that is so significant for the future and for climate protection.