Crude Characterization and Process Control by Topnir Technology

By Dr. Didier Lambert, Ph.D.

To remain competitive and profitable, refiners have to work more and more with opportunity crudes that provide a cheaper feedstock but are more challenging to process. Indeed, Crude quality is changing rapidly leading to the necessity to evaluate Crude oil quality more often. It becomes mandatory now to characterize Crude feeds more frequently and not to rely only on crude assays.

Based on more than 25 years of experience and expertise, a unique technology addresses this challenge flawlessly. Topnir technology is able to identify and characterize any Crude mixture. In less than one minute, neat crudes ratios are predicted from any crude mixture, as well as all properties such as full distillation curve (TBP), API, TAN, Sulphur, SARA and more. Moreover, the full Crude Assays, integrating distillation cut yields and properties, can be delivered as well.

Topnir is a field proven on-line technology used worldwide for more than 25 years.

Topology modelling with NIR spectroscopy

The best spectral domain to analyse Crude oil was identified in the Combination Band, lying between 4.000 and 5.000 cm-1, which provides the best information in terms of chemistry, accuracy and robustness.

- The spectrum of any product is directly linked to the physical and chemical properties of this product. It is like a fingerprint of the product, each product has a unique fingerprint, like any human person. Topology modelling is based on spectra matching, working through pattern recognition and database densification. It means any spectrum is used as a fingerprint of the sample.

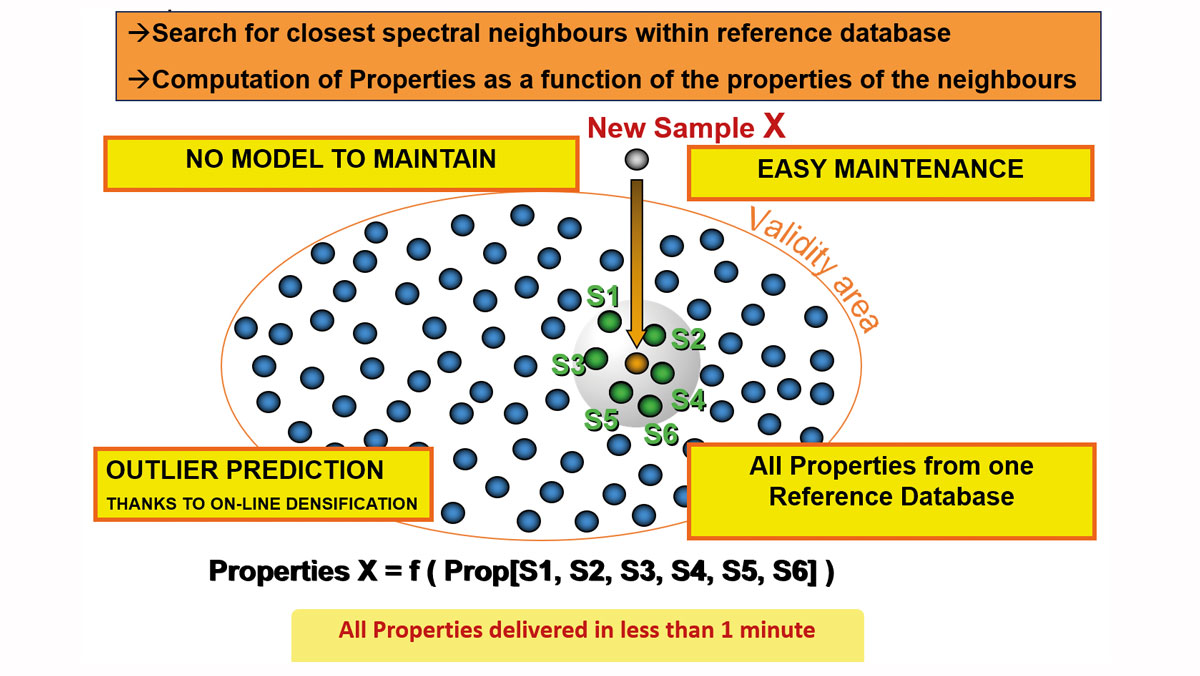

- Thus, this spectrum is positioned in a database and characterized with the closest neighbour spectra. Then the full set of properties of any new sample is predicted from the average of properties of closest spectra (see Figure 1). Indeed, the closest spectra means samples having the closest physical and chemical properties.

Only one single model is used for all the properties, the quality prediction being performed from a reference database. The fact to have one single model for all the properties gives a better robustness and reliability to the prediction.

This approach keeps the inter-correlations between the properties and makes sense in terms of sample chemistry.

These spectra matching approach allows for instance the prediction of the full distillation curve as per ASTM Standards by keeping the continuity of distillation process.

Topology model is not limited with the number of properties as it deals with a single reference database. So, the number of properties can be easily extended if required without impact on modelling effort.

Crude Distillation Unit, NIR spectroscopy and Topology model

The early applications of Topnir for crude quality have covered:

- Oil production sites with variable quality at well clusters, the objective being to have a crude commercial grade at gathering stations

- Crude Distillation Units (CDU) in refineries with diversified crude slate, the primary objective being to avoid transient throughput reduction during crude swings

The first on-line NIR application was installed at the BP Lavera refinery in 1992, using the topology modelling technique. Typically, about 40 quality determinations at high frequency on crude feed and rundowns were used by the CDU advanced control application.

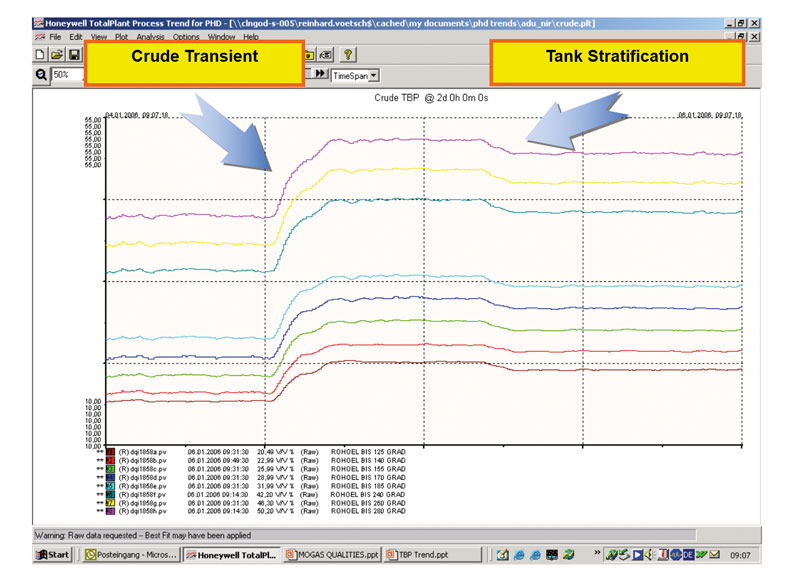

A screen shot from DCS on TBP on-line prediction is shown hereafter on Figure 2.

This figure shows the efficiency of Crude feed quality monitoring during a transient between two Crude Oil tanks. Even tank stratification can be detected and quantified as shown by Figure 2 thanks to Topnir. This analysis has no equivalent in terms of on-line system giving the full TBP every minute.

The precision and accuracy of the TBP curve is coherent and in agreement with the relevant ASTM Standards methods.

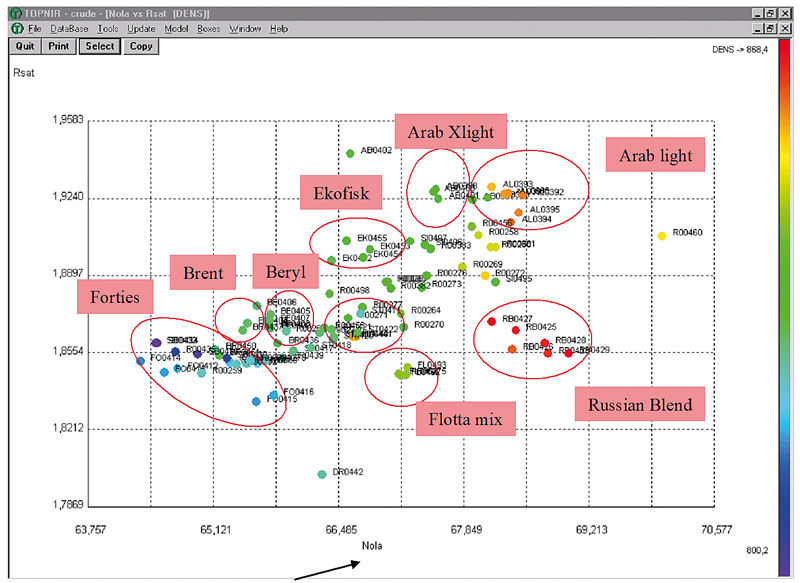

Another example of the capability of Topology is shown on Figure 3 with a very efficient spectral discrimination between origins of Crude Oils. This achievement is possible because Topology software uses the whole NIR spectra as well as specific proprietary axes to plot the samples.

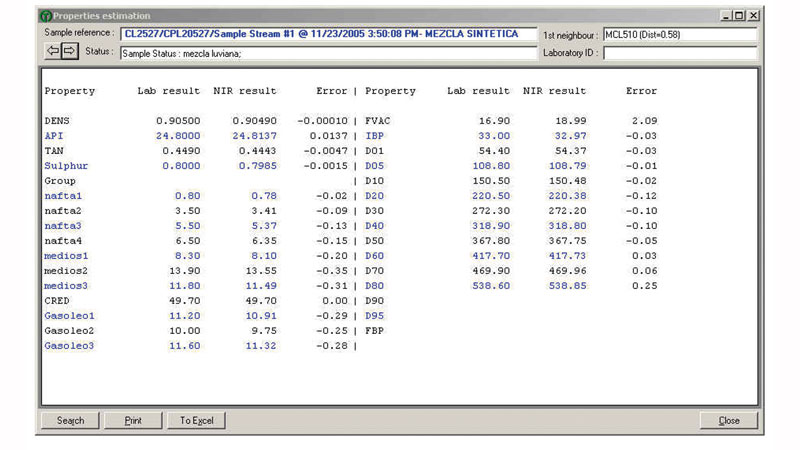

A typical validation stage display is shown on Figure 4 where all properties predicted by Topnir are compared with Conventional results. All properties match the standard measurements from Conventional analysers perfectly. Thus, critical properties such as TAN, Simdis, Assay Yields, Sulphur, API, density are accurately predicted on-line by Topnir every minute.

All the advantages described above allow reliable Advanced Process Control (APC) with effective closed loop control. It can be mentioned:

- Improvements in:

Fractionation control, effectively using side streams qualities in real time

Cut point control by APC

Response to crude mix quality swings, reducing transient products down grading such as Gasoil and Residue

- Yield increase of selected streams without quality impact, in particular Cloud and Freeze Points

- Throughput Increase by better swing procedure, using real time TBP of Crude mix

- Better tuning of LP and Scheduling models

All these advantages can easily capture benefits of several million USD per year.

Other Applications of TOPNIR

Several other Topnir applications have emerged in a context of increasing crude slate and logistics complexity.

In particular, crude traders have diversified their supply sources with opportunity crudes (including very heavy, high Sulphur), distressed cargoes, condensates, shale oil and other unconventional crudes. The receipts and storage facilities have generally not been designed to cope with such a diversified crude slate and the crude tank farm can face a severe problem of crude segregation and mitigation of compatibility issues.

Thus, Topnir technology is also applied in Crude receipt and storage, using Topnir fingerprints to check in real time the conformity of Crude oils upon arrival.

Crude blending is used in some refineries to provide adequate feed quality to CDU and to saturate the constraints. In that respect, Topnir spectral blending is a very efficient tool to compute the optimal blend recipes.

Requirement for fast Crude assay prediction is really a challenge for each site. Using Topnir technology enables more up-to-date crude oil assay information and a better prediction of cuts on non-linear properties. Thus, Topnir is able to predict the full Crude Assay, integrating distillation cut yields and properties, only from Crude oil spectra, representing hundreds properties in less than one minute.

Conclusion

Field proven Topnir solutions enable the capture of significant benefits in a Refinery:

- For Planning and scheduling, with a better tuning of linear model for planning and optimization of crude slate as well as a faster crude quality information to scheduling system for better adherence to optimal plan

- For Crude tank farm, with a more efficient crude segregation and crude compatibility management as well as an easy detection of crude tanks stratification

- For CDU, it allows faster crude swings without loss of throughput and with more stable downstream operations

Typical benefits collected from installed basis are within the range of several million USD per year.

Topnir on-line applications allowing molecular characterization are becoming essential for future complex crude slates and crude to chemicals plants.

Topnir technology was initially invented and developed by the founders in BP and was subsequently bought out to establish Topnir Systems. With more than 20 years of business experience worldwide alongside every major Oil & Gas Company, their skills and expertise into NIR systems and modelling has led to an extensive and diverse installed base with the delivery of more than 150 applications and 40 patents.

In 1989, Topnir was the first world-wide to implement an online application designed to measure and control octane number for gasoline production, as well as first NIR on-line application worldwide on Ethylene Plant Naphtha feed (1989) and Crude Oil Distillation – CDU (1991).

Dr. Didier Lambert, Ph.D., is the CEO and founder of Topnir Systems Company. He has over 30 years of experience in Refining and Petrochemicals, including International Project Management and Business Development in BP and ABB Group.

Dr. Lambert is the inventor of more than 30 patents and the recipient of the 1989 Petroleum Engineer’s Award for Octane Number prediction by NIR.