Advanced Tools of Halliburton to Help Operators to Save Well Time and Costs

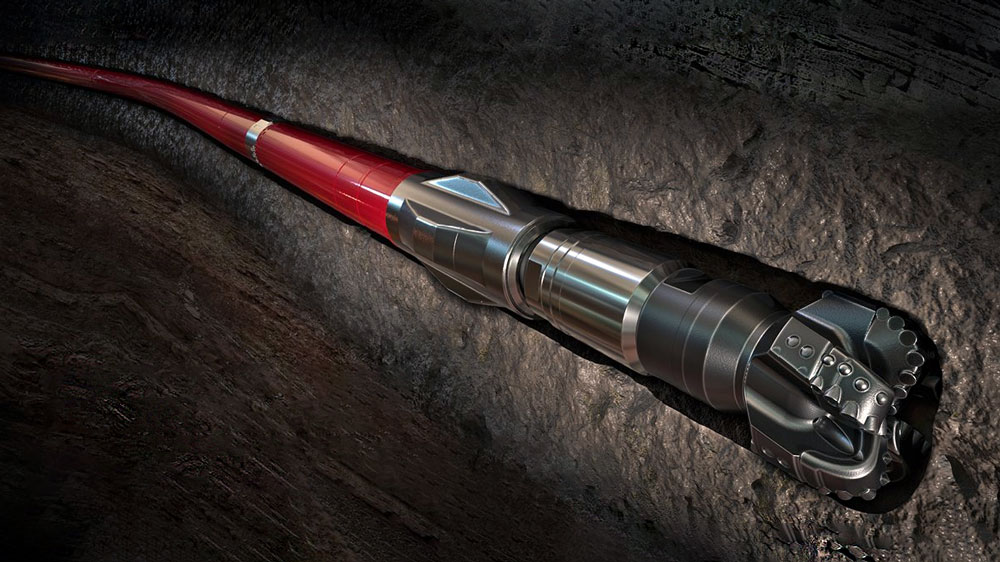

Halliburton just released NitroForce, a new drilling motor that provides increased power and performance to complete longer laterals faster and with greater control. The motor delivers high reliability helping operators reduce potential motor failure and increase drilling speed to save well time and costs.

“As operators focus on greater operational efficiency, we designed a motor with the highest horsepower in the oil and gas industry to drill faster and reduce non-productive time,” said Lamar Duhon, vice president of Halliburton Sperry Drilling. “Using this new motor allows operators to drill more consistent wells to increase their production.”

The NitroForce motor delivers longer runs with less wear by using new proprietary Charge™ elastomers and a stronger transmission, power section and bearings that work together to withstand high loads and torque. The design allows for a higher flow rate for improved hole cleaning and increased rate of penetration, which accelerates well delivery. By extending lateral lengths, operators can increase reservoir contact, minimize trips and reliably complete the curve and lateral in a single run.

In the U.S. Midcontinent region, the NitroForce motor completed a 10,000-foot record run by drilling a 40 percent longer lateral with a 30 percent greater rate of penetration compared to a conventional motor.

Halliburton also recently introduced Streaming Unconventional Well Test Data Retriever (SPIDRlive™) – an unconventional well testing and fracture interaction monitoring technology that acquires real-time well data without the need for intervention to reduce costs and improve fracture understanding for greater recovery.

The SPIDRlive retriever combines quartz-based hardware and proprietary modeling software to capture high-resolution, high-accuracy and high-frequency data from the wellhead without running downhole equipment. In unconventional wells, operators can acquire data to optimize fracture design or perform an engineered flow-back to improve well performance. In multiple wells, operators can utilize the streaming capability for remote monitoring of fracture interactions in offset wells.

“We designed this technology to deliver critical well data to the surface with an emphasis on simplicity and accuracy to improve performance,” said Daniel Casale, vice president of Testing and Subsea. “The retriever is a versatile tool with applications throughout the well lifecycle to enhance reservoir understanding while reducing costs.”

In West Texas, an operator recently deployed SPIDRlive on multiple offset wells to monitor for fracture interactions. During the fracture treatment, SPIDRlive transmitted data via a wireless signal to a field edge device and then streamed into a secure cloud application for the client to visualize. The streaming data indicated an interaction on a neighboring well pad alerting the operator of potential consequences during their production optimization campaign.

About Halliburton

Founded in 1919, Halliburton celebrates its 100 years of service as one of the world’s largest providers of products and services to the energy industry. With approximately 55,000 employees, representing 140 nationalities in more than 80 countries, the company helps its customers maximize value throughout the lifecycle of the reservoir — from locating hydrocarbons and managing geological data, to drilling and formation evaluation, well construction and completion, and optimizing production throughout the life of the asset.