Fusematic Bonding System

Taking Friction Welding into a New Era of Portability, Controls, Safety & Capability

The Fusematic Bonding System (FBS) is safer, faster, and more economical than other welding processes for specific materials joining applications. Fusematic Bonding Solutions join materials on the surface, underwater and in outer space.

Fusematic Bonding™ technology uses friction rather than flame to automatically bond metals at the molecular level, literally fusing them together achieving consistent, incredibly high-strength bonding in a fraction of the time, in a safer environment, and at significant cost savings.

What is Friction Welding?

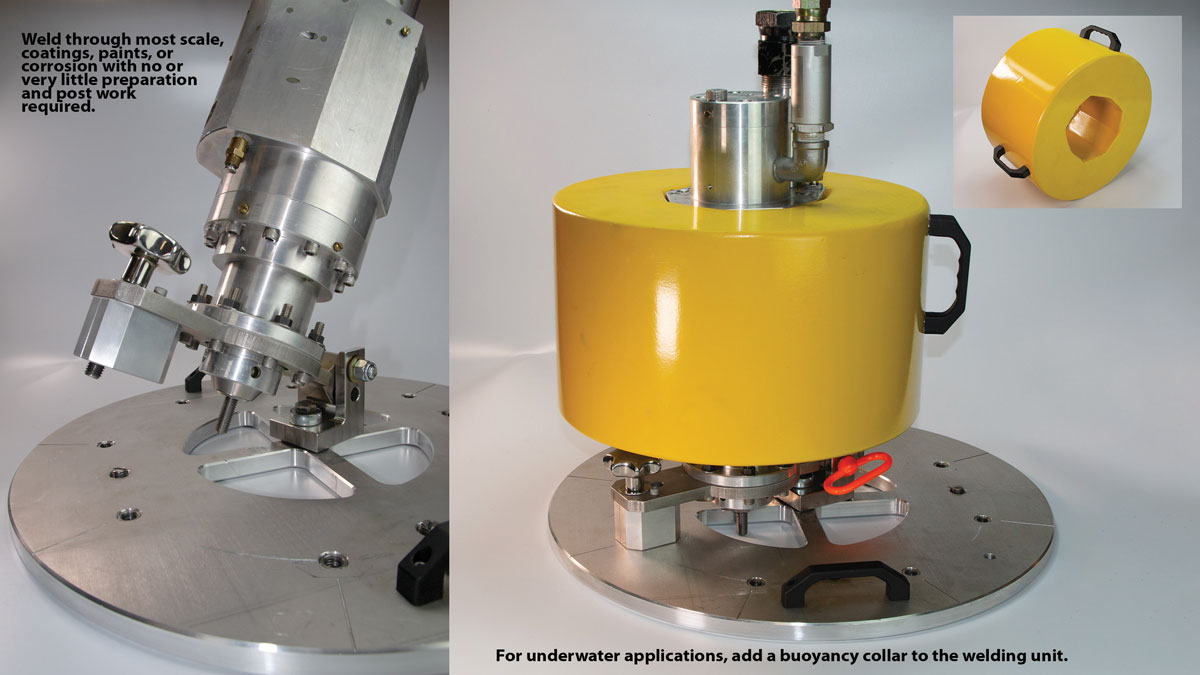

Friction welding, also known as solid-state rotary friction welding, is an industrial process which creates a permanent bond between two metallic surfaces by utilizing friction. Fusematic’s Bonding Systems use compressed air to forge two metals together to attach engineered, industrial fasteners made of similar or dissimilar materials. The systems can be utilized for numerous applications on a wide range of industrial facilities and in a marine environment to facilitate construction, retrofitting, and repairs in many heavy industries.

Welding Portability, a Game-Changer for Heavy Industries

Fusematic Bonding System is taking friction welding into a new era of portable applications. Fusematic’s system and associated machine tools can be used onshore, topside, underwater, and in hazardous and explosive work environments. No surface preparation or hot work permits are required. In-field applications save time and money over traditional welding systems with a portable and safe engineered fastening solution for bonding metals and composites together using the latest advancements in engineered fastening solutions technology.

Technical and Commercial Advantages over Traditional Systems

The Fusematic portable system is an alternative to traditional welding that is quickly disrupting welding across several heavy industries. Advantages include:

Deployable on Operating Fix Assets Transporting, Processing or Storing Hazardous or Combustible Content in Explosive Atmospheres

- Man-portable, so technicians can easily transport the welding machine tool and peripheral components into compact areas in the field or even underwater

- Systems easily deployed to on-site work areas. Repairs can be made without incurring unscheduled shutdowns of the operating assets

- Fusematic provides training and deploys equipment to local contractors for timely, efficient applications

Superior Performance Metrics

- Achieves consistent, incredibly high-strength bonding in a fraction of the time

- Welded joint integrity is very reliable

- Capable of joining dissimilar metal combinations

- Fast and reliable

Safety

- The Fusematic apparatus uses controlled friction, instead of flame or arc, to permanently attach engineered fasteners, eliminating concerns over fire and explosions

- Powered by compressed air, the system eliminate the need for hydraulic, oxygen and acetylene or electrical components

- Sparks from welding and cutting metals can easily result in devastating fires for refineries, industrial plants, and shipyards, to name a few. These risks are eliminated

- No risk of sparks or flames that become ignition sources

Substantial Cost Savings

- Reduced operations shut-down time – no need to empty tanks, pipelines etc., prior to welding operations

- less-skilled labor can run the equipment

- higher production rates

- precise, repeatable process improves efficiency

Environmentally friendly

- Environmentally friendly, no fumes or waste

- No filler metals, fluxes, or gases required

“The FBS is profoundly changing the way our customers approach their welding operations. Using this tool, repairs can be made without shutting down, draining, and cleaning oil and chemical storage tanks, pipelines, or dry-docking water vessels, allowing operations to run uninterrupted,” says John Griffin, President of Fusematic Corporation. “An unskilled technician with minimal training can use the FBS to weld an engineered fastener in 15 minutes or less. Welding fastener attachment points is now four times faster, with guaranteed joint integrity and no risk of sparks or flames that become ignition sources.”

Industry experts like Ernest D. Levert, Sr., a Lockheed Martin Fellow and former President of the American Welding Society, says about the technology: “The Fusematic Bonding System is by far safer, faster, and more economical than other welding processes for specific materials joining applications. Fusematic Bonding Solutions join materials on the surface, underwater, and in outer space. Wherever high-strength, consistent bonding is required, Fusematic should be on-site as a vital part of any operation.”

Industries that Need Fusematic and the Fusematic Value Added Propositions

Their markets can be summed up in one basket… Heavy Industries.

Heavy Industries include the 24 hour/7 days per week/365 days a year continuous operations in manufacturing, maintenance, and repair activities in the energy, maritime, inland marine, military… onshore and offshore, topsides and underwater markets and even in outer space. They are bringing together and incorporating the latest elements in Industry 4.0, Intelligent Welding, AI, IIot, machine learning, robotics, big data, autonomous and remote operations. Their disruptive technology impacts the $142 billion welding machine and welding supplies market combined with the engineered and industrial fasteners markets.

Corrosion Management is a significant area where Fusematic Bonding System can make a significant impact on heavy industry.

It is estimated that the corrosion market generates $2.5 Trillion in costs spend worldwide with costs upwards of 3-5% of US GDP to mitigate. Any oil and gas refinery, petrochemical plant, offshore energy production platform, power plant, pulp, and paper plant, pharmaceutical plant, ship repair, conversion, and modernization yard, or liquids and gas storage facility’s assets will suffer wear and tear over time due to corrosion and erosion, therefore, compromising the integrity of the assets which has significant direct and indirect costs to mitigate. Organizations that have Corrosion Management Programs are recognizing the need to operate at the absolute lowest cost with the absolute highest reliability and safety standards.

A sound technical corrosion control solution incorporating Fusematic Bonding Systems will result in a positive ROI. Use of Fusematic delivers immediate cost-effective repair, retrofit, and maintenance solutions to strengthen the integrity of the asset without the asset owner having to cease operations and without the risk of causing an explosion if the activity occurs in a hazardous/explosive operating environment.