Halliburton retrievable bridge plug helps ensure stability and safety

Halliburton was working with a major operator in Norway on its drilling operations in a mature field in the North Sea. While discussing upcoming well challenges with the customer, Halliburton recognized an opportunity to introduce the newly released Intercept® retrievable bridge plug, which would offer the customer a gas-tight V0 barrier during batch drilling and completions.

Two jobs were successfully completed with no issues or non-productive time (NPT), solving the customer’s challenge to have V0 barriers in place while temporarily abandoning the wells.

Challenge

This operator needed to rent barrier plugs in order to temporarily abandon its wells to drill and run batch completions. Normally, the operator rented bridge plugs from another service company. Halliburton had to convince the operator that the Intercept retrievable bridge plug would lower risks and save time since it did not require left-hand rotations and hang-weight below to operate down hole.

Solution

Halliburton provided specific tool data as it related to the well conditions, sizing, and temperatures in order to help ensure that the Intercept retrievable bridge plug would perform well in the environment. Halliburton also explained that the plug is versatile since it does not require hang-weight below to set, which saves rig time. Should well operations require it, however, the plug can handle significant pipe weight below, saving trip time and reducing cost. Since the plug does not require left-hand rotation, it reduces the risk of accidental disconnection of the work-string or work-string components.

A Global Critical Well Review for these specific jobs was executed in order to prove Halliburton commitment to the operation.

Results

One 9 5/8-in. Intercept bridge plug was installed in Well No. 1 to cover the shallow barrier. Two 9 5/8-in. Intercept bridge plugs were installed in Well No. 2 in order to cover the deep and shallow barriers. All three Intercept bridge plugs were installed successfully, incurring zero NPT. The operator was pleased with the service and performance of the Intercept retrievable bride plug and has continued to use these plugs in three other wells.

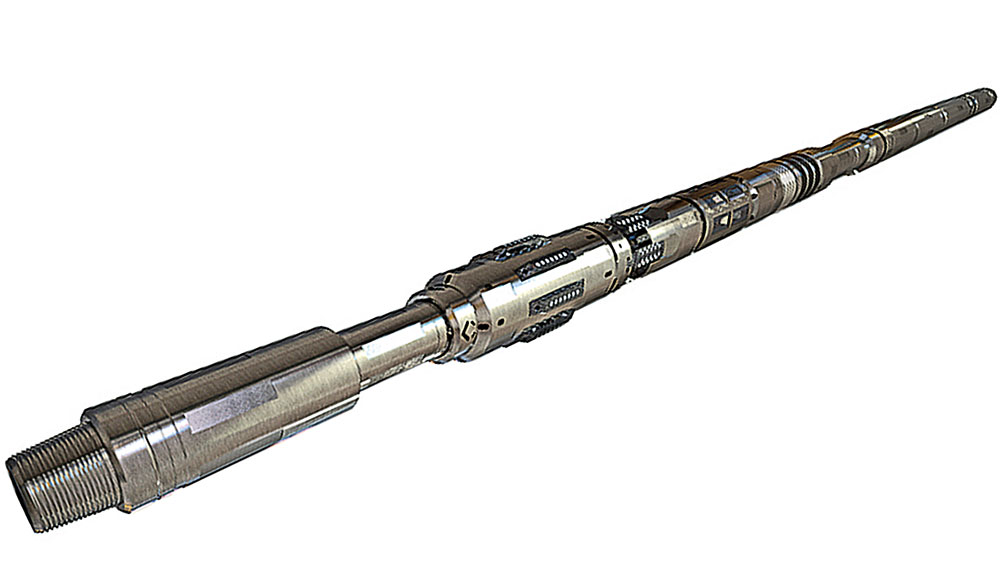

Intercept® Retrievable Bridge Plug – A reliable barrier in the casing

The Intercept® retrievable bridge plug (RBP) is a gas-tight, well-suspension plug ideal for dual-barrier applications. Wellbores lacking a gas-tight seal can mean loss of control and an undesirable release of hydrocarbons that pose safety and environmental hazards. The Intercept RBP prevents these hazards and complies with ISO 14310 and API 11D1 V0 standards for wellbore isolation.

Reliable in environments ranging from inland waters to ultra-deep water, the Intercept RBP sets with simple work-string operation. It consists of packer-type sealing elements, bi-directional mechanical slips, and a ball valve, which can be opened and closed without pipe rotation. It requires no hang weight to set, eliminating the time to deploy drillpipe beforehand, yet it can handle significant pipe weight, reducing trip time and costs while enhancing safety. Additionally, the tool requires no left-hand rotation, thus reducing the risk of unintentionally disconnecting the work-string or bottom-hole assembly.

Ensuring stability and safety during:

- Test and maintenance of the blowout preventer

- Maintenance of the wellhead

- Testing the casing

- Short- and long-term well suspension

- Emergency suspension due to weather or adverse conditions

Key benefits

- Complies with ISO 14310 and API 11D1 V0 standards for wellbore isolation

- Quick and easy operating procedure

- Requires no left-hand rotation

- Requires no tripping tailpipe, reducing rig time and cost