Robots taking over!

The ‘hows’ and ‘whys’ of making our lives easier and cheaper

No, it’s not another weak Hollywood plot; it’s about living easier, cheaper, cleaner lives. Robots in industry are by no means something new. Actually, they’ve been around for a good 20 years, with uses documented as far back as the eighties. So why should we bring it up again? We do it because now it’s all interlinked courtesy of digitalization and Internet of Things. Ok, calm down, we’re still far from real artificial intelligence and humanoid robots stealing our jobs from under us, that’s not the case. But what if it was? An industry where we don’t have to get our hands dirty so often, perform tasks ten times faster at half the price and without affecting the environment sure sounds like a great idea. Intelligent people always sought easier solutions to their problems and sometimes the best solution is to have somebody else do your job. Delegation is a skill after all. But, are our robotic little and big friends up to the task? And if they aren’t, it’s our job to make them better versions of ourselves. Let’s see how exactly do offshore robots fit in the current and future oil and gas industry.

Make no mistake about it, as tasks are shifted from human responsibility to robotic one, the global work market will also undergo some dramatic changes. With more and more technological wonders popping up every day, this transition and the capacity to adapt to it will make or break certain companies, as the Fourth Industrial Revolution will wait for no man or machine alike. Stationary robots or land, underwater and aerial drones are sometimes adopted and invested in as soon as they leave the assembly line with leaders in the Oil & Gas industry reporting significant business interest. In consequence, they expect an important change in the division of work tasks come 2022. Whereas now work is mostly covered by human employees, the balance may shift towards machine labour pretty soon.

BP Global is one of the leaders of change, specifically in their Gulf of Mexico platform – Thunder Horse. Where once offshore operators had to conduct lengthy inspections of the facilities, now this task has been undertaken by crawlers and flying robots independently of the weather conditions. A process that was once described as lengthy and tedious, on account of limited human reach, is now markedly improved by the addition of robots which do the job faster and also yield considerably more data than their human counterparts. After all, capturing images of pipes and other machinery is easier with built in 360-degree cameras. So, BP’s Digital Innovation Organization (DIO) brought in their technological knowhow to the table, offering autonomous machines with digital sensors and analytics, practically transforming this inspection from an observational activity to a quantitative science.

Since their first trial run in 2016 proved so fruitful, they have added a magnetic crawler which navigates the hull structure and a drone which surveys the riser pipes facing away from the hull. According to Dave Truch, technology director for DIO: “Taken together, the drone and crawler were able to capture not only 360-degree views around the entire pipe, but also the imagery included useful information for surrounding structural elements”[1] and judging from the attached video on their website, manoeuvring the robot is a piece of cake – they just use a game controller.

The article continues below the photo.

The tech specs are even more interesting. Their crawler features a high definition camera and rare-Earth magnets and since no electromagnetics are used in the inspection, a power cut would not affect it in the slightest. Regarding the drone, it is built with a high-performance processor in charge with maintaining flight controls, plus a stabilized high-resolution camera for those blinks and you might miss it details. With a flight capacity ranging from five to eight meters from the piping, the powerful lens comes in handy when you need to zoom in on something. Work security is still the norm so the crawler also comes equipped with a wireless gas detector which can send alerts up to 300 meters in case of danger. If this wasn’t enough, the drone carries an optical gas imaging camera and the team themselves use a gas imaging camera on the platform’s catwalk to monitor activity.

Testifying to BP’s devotion to state-of-the-art technology is the drone itself; Dave Truch advocates that not any common drone can take on this task, even high-end commercial drones might not be enough for the job with chosen few being able to handle it. But it’s worth the price of admission according to Bill Broman, subsea operations manager: “We collected a much larger volume of data that was significantly higher quality. The high-definition cameras on the drone and crawler enabled us to get continuous feeds of the imagery, rather than a series of slices.”[2] Seeing the bigger picture surely has its benefits, just compare several weeks of work to a couple of hours. With such a resounding success we can be sure this will be implemented to other platforms in the future. Still, BP states this is just the beginning. They have also mentioned using the crawler for their downstream operations, namely the Cherry Point refinery in Washington where the hydrocracker reactor is inspected for microscopic cracks via ultrasound technology. The crawler does this in one hour, as opposed to 23-man hours during a planned shutdown. I believe the benefits speak for themselves.

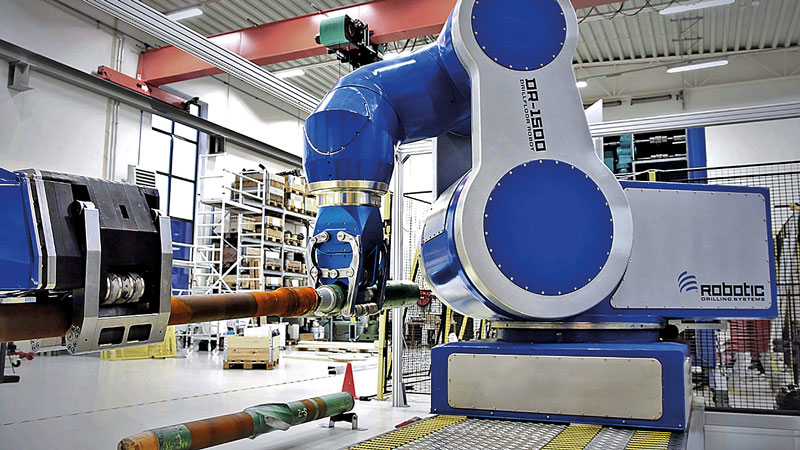

Things like safety and efficiency were also mentioned by Torgeir Olsen of Odfjell Well Services in his interview with the magazine in March of 2017. Also touching on the importance of digitalization and its implementation, he hinted that the sky might not actually be the limit since robots may be used to drill on Mars too. Since then, Odjfell and Statoil (now Equinor) have sold their shares in Robotic Drilling Systems (RDS) to Nabors Industries. Along with the sale came a Memorandum of Understanding which establishes cooperation between Nabors and former shareholders in order to still have access to robotic technologies.

The article continues below the photo.

Nabors now feature the Canrig® drilling equipment brand which combined with their Rigtelligent™ operating system, provides companies with improved efficiency and drilling performance. Their Electric Drill Floor Robot has a 1500-kilogram load capacity and automates all pipe and tool operations with the help of various automated grippers, spinners, clamping and seven axis motions. Since it’s all integrated, the robot can seamlessly transfer power and communicate with other rig components. Also, given the built hardware controls and standard electric components it makes for an easy installation and low maintenance. Another one of their heavy hitters is the Electric Robotic Roughneck which features 270 kNm of torque and provides full control of all parameters when dealing with drill pipes and casings. It also comes with a triple grip torque wrench with high accuracy control and 120 degrees total rotation per grip. Coming to prevent incidents caused by pipe handling or dropped objects is the iRacker® offered in electric and hydraulic-powered units. With its autonomous tubular handling system, it enables completely hands-free pipe handling and weighs each pipe, measures tubular lengths on the catwalk and determines the tubular diameter for the mouse hole and power slips. It can be easily installed into any AC Rig and has perfect connectivity with the Rigtelligent™ control system, giving the driller full control over all drill rig operations from his cabin.

Equinor is also kind enough to present a robot collection of their own. Eelume, the snake like robot is a type of underwater intervention vehicle which uses thrusters to swim around subsea installations. Its main attributions are turning valves on and off and filming pipelines to check for faults and does so effortlessly due to its shape and increased flexibility and manoeuvrability. It also features enhanced customization possibilities given its modular build. Weather conditions are no object and the Eelume can dwell indefinitely on the seabed.

A long-time in the making, Hugin seems to be the ultimate autonomous underwater vehicle given its hydrodynamic shape, accurate instruments and excellent battery capacity. As the fastest and most accurate seabed mapping device, it’s a staple of any major oil field enterprise on the Norwegian continental shelf. Featuring complete autonomy, no cables or remote control needed, it also sports a gyroscope, axelrometer, Doppler legs, echo sounder and sonar systems. It’s so good at finding small objects underwater that it has also been used in mine hunting.

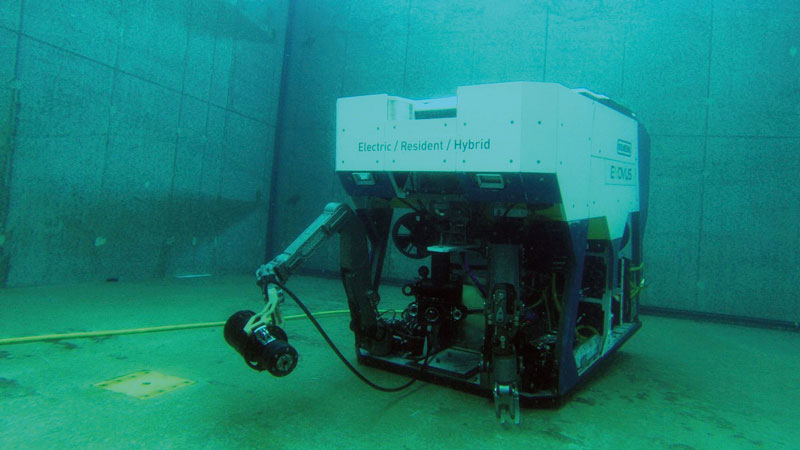

Since we’re talking about digitalization, welcome to E-ROV (Empowered Remotely Operated Vehicle), the so called ‘Tesla-submarine’ which can be controlled from anywhere in the world courtesy of a fast Ethernet connection. This is possible thanks to Equinor’s installation of a fast 4G network on the Norwegian Continental Shelf, with the E-ROV receiving and transmitting via a buoy on the surface. Having an on-board battery and available subsea charging station makes the submarine independent, racking in cost, time and environmental advantages.

The article continues below the photo.

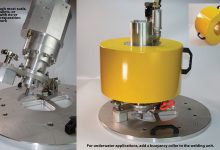

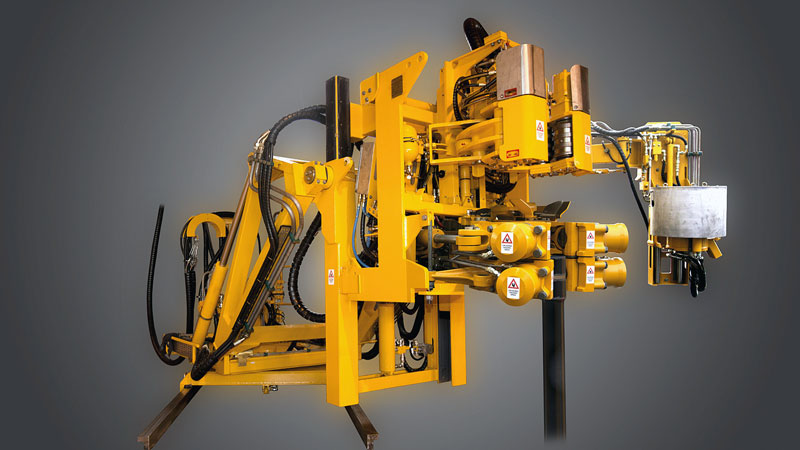

National Oilwell Varco brings their own version on the Iron Roughneck called The HydraTong ARN which features full drilling process automation. The robot comes with integrated tools such as automatic bouncers, mud buckets and high-resolution cameras with fast image processing to streamline the drilling process making a manual operator obsolete.

The article continues below the photo.

Last but not least we may talk about the HX Cleaning robot. Given the task to clean and inspect tube heat exchangers on platforms and onshore installations it will be able to do so without the added inconvenience of having to stop production, because as we know it, time is money. Since no human labour is involved this means fewer accidents and since chlorine has been swapped for high pressurized water, the robot is also environmentally friendly.

All these are but a few examples, there’s no telling what engineers have cooking up in their labs and what prototypes will hit the shelves in the world of tomorrow. With digitalization slowly becoming the norm who knows what will surprise us next. In 20-30 years, the innovations of today will likely seem as something usual and we’ll be wondering how we ever handled these jobs without the help of robotic assistants. But in order for that fantasy to come true we need to accept it and realize its importance today. Some companies have already joined in on the phenomena. The others might have to pay a dear price for passing on this opportunity.

[1] https://www.bp.com/en/global/corporate/bp-magazine/innovations/robot-technology-thunderhorse-gulf-of-mexico.html

[2] https://www.bp.com/en/global/corporate/bp-magazine/innovations/robot-technology-thunderhorse-gulf-of-mexico.html