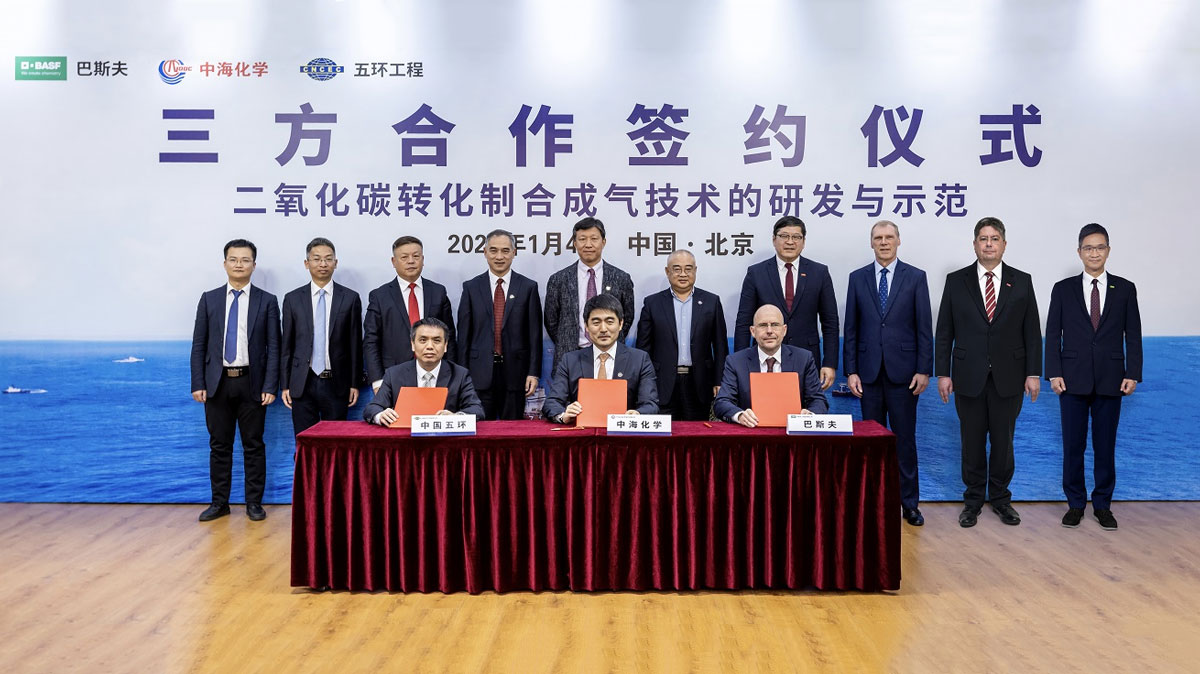

BASF, China BlueChemical and Wuhuan Engineering Partnership over Low-carbon Development and Utilization of Marine Gas Resources

BASF, world’s largest chemical producer, partnered with China BlueChemical, a leading natural gas producer, and Wuhuan Engineering, a chemical engineering company, over low-carbon development and utilization of marine gas resources in South China Sea.

Marine gas, unlike the commercial natural gas, contains high concentrations of CO2. The gas needs CO2 removal to be usable for downstream large-scale applications.

The process of separating CO2 from natural gas not only increases energy consumption, but also contributes to yield loss and direct carbon emissions. These issues limit the systematic development and utilization of natural gas with high CO2 content.

BASF will leverage its extensive expertise in catalyst development and will collaborate with the two companies to solve these challenges. Through technical innovation in reforming catalysts, special reactor design and related process technology development, BASF’s solution will improve process energy efficiency and carbon efficiency beyond existing commercial catalyst and process technology. The partnerships will promote lower-carbon development and utilization of marine gas resources, and ultimately achieve an economically competitive and environmentally friendly commercial process.

“Combining the advantages of our oil and gas development capacity in the South China Sea and BASF’s expertise in catalyst technology, we hope to seize the opportunity to establish a good strategic partnership for cooperative development of green and low-carbon footprint using marine gas,” said Wang Weimin, Chairman of China BlueChemical Limited Company.

“With our superior process research and development as well as engineering practice capabilities, Wuhuan will complete the design and research tasks with guaranteed quality. Through our joint efforts, we can effectively resolve the challenges of CO2 rich oil and gas exploitation and large-scale resources utilization of CO2,” noted Cheng Lachun, Chairman of China Wuhuan Engineering Co., Ltd.

“With our product development, scale up and production capabilities, BASF’s catalysts can significantly contribute to the improvement of the process energy efficiency and carbon efficiency for marine natural gas utilization. Through our joint efforts, we aim to develop a commercially viable process for utilizing marine gas with a substantially reduced CO2 footprint. We consider it an important step towards realizing our mutual target of carbon neutrality at economically competitive conditions,” added Dr. Detlef Ruff, Senior Vice President Process Catalysts at BASF.

About BASF’s Catalysts Division

BASF’s Catalysts division is the world’s leading supplier of environmental and process catalysts. The group offers exceptional expertise in the development of technologies that protect the air we breathe, produce the fuels that power our world and ensure efficient production of a wide variety of chemicals, plastics, and other products, including advanced battery materials.