UK Blue Hydrogen: Clean H2 Facility in Teesside

bp has agreed Memoranda of Understanding (MoUs) with a series of new potential customers for its proposed clean H2 production facility in Teesside in north-east England.

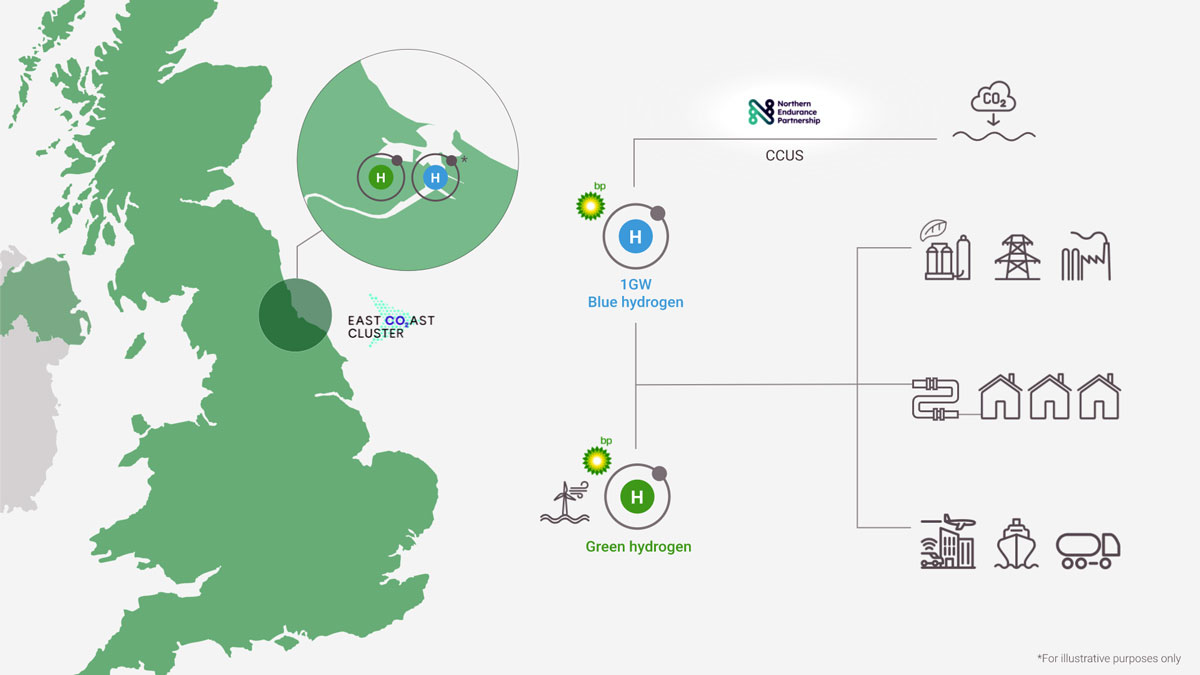

In March, bp announced plans for a clean hydrogen facility in Teesside (H2Teesside) that would aim to produce up to 1GW of ‘blue’ hydrogen – 20% of the UK’s hydrogen target – by 2030. At the same time, it announced it had signed initial MoUs to scope the supply of hydrogen to chemicals manufacturer Venator and gas distributor Northern Gas Networks.

bp has now signed MoUs with four further potential customers – with existing or planned new Teesside operations – for hydrogen produced by the project. These can support and accelerate the development of the Teesside hydrogen cluster and decarbonization of industrial users in the area. The new MoUs are with:

- CF Fertilisers, one of the largest global producers of ammonia and ammonia-based fertilizers products, to scope the supply of clean hydrogen as fuel to reduce hard to abate combustion emissions at its Billingham plant, whereas feedstock sourced CO2 would be sequestered via the Northern Endurance Partnership project.

- Mitsubishi Chemical Corporation, a leading global manufacturer of chemical products, to scope the supply of clean hydrogen to its methyl methacrylate production plant in Teesside (formerly operated as Lucite International).

- Sembcorp Energy UK, owner and operator of utilities and services infrastructure at Wilton International, an industrial park in Teesside, to scope the supply of clean hydrogen to its combined heat and power plants and developing hydrogen infrastructure at Wilton International to enable hydrogen supply to third parties.

These companies are seeking to decarbonize existing operations in Teesside by switching fuel from natural gas to clean hydrogen, enabling their manufacturing facilities to produce low carbon products as society progresses towards a net zero future.

Finally, bp has executed an MoU with alfanar Company to scope the supply of clean H2 to alfanar’s waste-to-sustainable aviation fuel (SAF) plant, currently under development, in Teesside.

alfanar Company represents the new project investments coming to Teesside, aiming to develop low carbon materials using clean H2 as a feedstock for production.

“Today’s announcement demonstrates the diverse range of companies and industries that can benefit from clean hydrogen. Teesside has all the attributes of a world-class clean hydrogen hub – the right natural resources, concentrated demand, potential for hydrogen storage and pipelines, ample access to CCUS and the right skills base. While the impact of investments may be felt most acutely in the north-east, the decarbonization benefit of H2Teesside is expected to be felt countrywide. Ultimately, these MoUs show how supply and demand can work together to accelerate the growth and delivery of a hydrogen economy,” Louise Jacobsen Plutt, bp’s senior vice president of hydrogen and CCUS, said.

Clean H2 is key to the decarbonization of hard-to-abate industries that have high heat requirements or require low carbon feedstocks. Access to clean hydrogen can reduce emissions, enable new, low carbon products, and offer the potential to unlock future fuels – for road transport, sustainable aviation, or low carbon marine fuels – and help secure a long-term low carbon future for the region.

In readiness for clean hydrogen production, and to engage the local supply chain, bp has launched an online portal for the UK supply sector to take part in the project development.

bp is encouraging UK-based suppliers to register their interest at the Teesside supplier portal, particularly those with connections across the north-east of England.

Transitioning Teesside into a low carbon industrial powerhouse

bp’s world-scale hydrogen project aims to produce 1GW of blue hydrogen starting in 2027, capturing and sending for storage up to two million tonnes of carbon dioxide (CO2) per year via the Northern Endurance Partnership (NEP) – equivalent to capturing the emissions from the heating of one million UK households.

Teesside has all the attributes of a world-class clean hydrogen hub – the right natural resources, concentrated demand, hydrogen storage and pipelines, ample access to CCUS, and people with the skills needed for this project.

With the initial phase aiming to produce roughly 20% of the clean hydrogen production goal stated in the UK Government’s 10 Point Plan for net zero, H2Teesside will supply a diverse range of customers, those already established in the region as well as new businesses attracted to this clean hydrogen produced at scale.

bp is also developing green hydrogen for use in various forms of transportation as well as industries to provide customers with choice, accessing the UK’s strong renewable energy potential.

bp’s extensive know-how in delivering complex projects and deep engineering and technical expertise, integrated with strong wind, trading, shipping and mobility businesses, means bp has not just the ambition to deliver first of its kind hydrogen production to the region, but also the ability and the experience to make it a reality.

bp brings over 100 years of operating experience and they are one of the largest producers of hydrogen in the world, safely and reliably generating and handling hydrogen and carbon dioxide at an industrial scale.

Industries in Teesside account for 5.6% of the UK’s industrial emissions and the region is home to five of the country’s top 25 emitters. This project aims to support jobs and to help regenerate the surrounding area, bolstered by local engagement with the communities – like vocational training and university outreach – to establish the region as a clean hydrogen centre of excellence.