90 years anniversary: First gas compressor station in Europe

Opening the first gas field on the current territory of Romania in 1909, through 2 Sarmasel Well, has determined the construction of the first gas transmission pipeline, Sarmasel – Turda, in 1914, of the first urban gas distribution network in Turda in 1918 and launching the gas activity in Romania. Gas consumption provided through Sarmasel – Turda pipeline increased rapidly through the connection of new consumers in Turda, as well as with the connection of new localities. Thus, from a consumption of around 50 million cubic meters/year in 1918, consumption reached 120-130 million cubic meters/year in 1923. This situation determined the exploitation of an important amount of gas in Sarmasel field, so its capacity to meet consumption fell.

Gas consumption was to grow towards 1926-1927, and the transmission capacity, following the decrease in pressure in the production wells, no longer covered consumption demand during winter. The solution found was to install a compressor station in the initial point of the pipeline, i.e. in Sarmasel, or building a new pipeline with a larger diameter. Although it had many supporters, it was considered that the second solution had a lower return than building a compressor station.

Thus, 90 years ago, without having any roads, machines and computers, it was managed to build, in only two years, as a European premiere, a gas compressor station.

The project of the compressor station was made by the Design Service of Sonametan, in 1926, and at the end of the same year the compressor aggregates were also ordered. 3 gas compression units were purchased, which could operate with simple or double action, thus making possible “the close monitoring of all variations of consumption within the limit of capacity for which they have been built”.

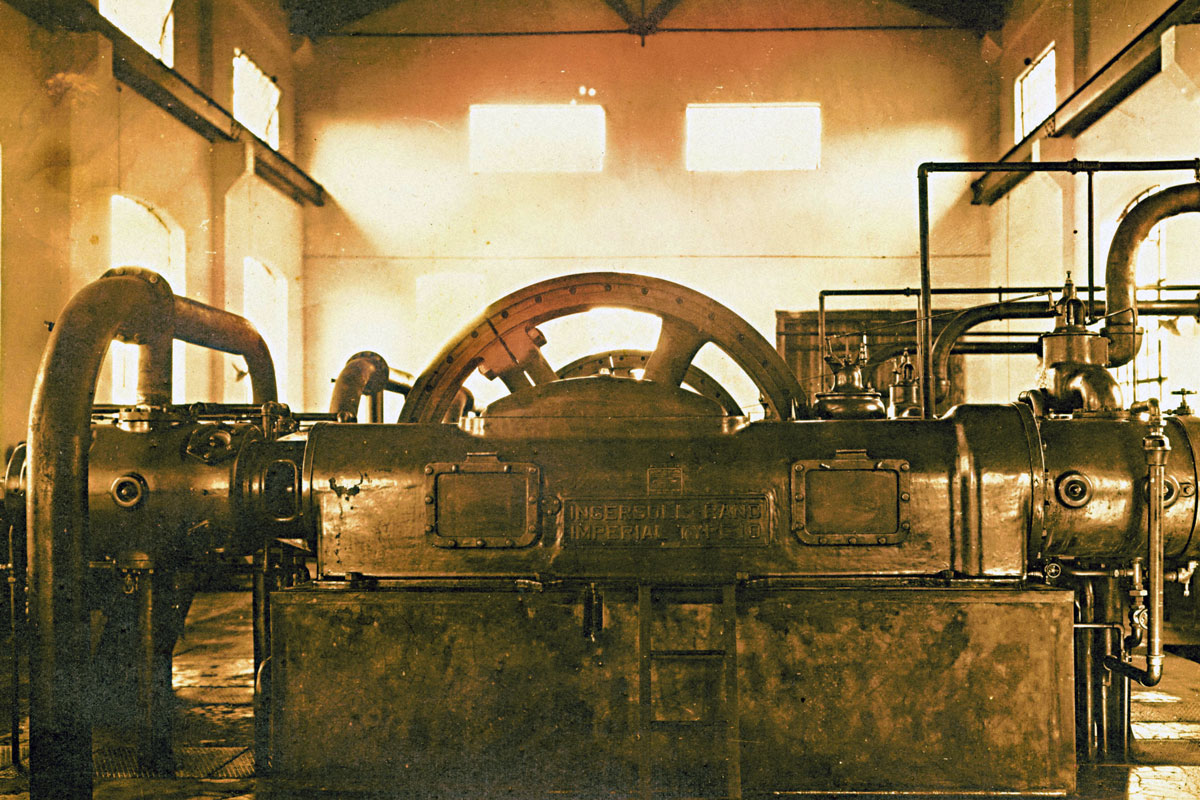

The characteristics of aggregates purchased from the U.S. in 1926 were: Duplex Ingersoll Rand compressors with a power of 200 hp per unit, so the compressor station reached a total power of 600 hp; speed – 225 rpm; maximum discharge pressure – 18 atm.

Construction works at the station started in the spring of 1927, ensuring the transport of aggregates, materials, the construction of foundations, production of the manifold, the construction of the water pumping station, the construction of the power plant, the construction of the water cooling tower, of engines, the construction of buildings of the compressor hall, workshops, offices etc.

Despite all difficulties faced by people those years – lack of any machine, oxen and horses being the only means of transporting materials, non-existence of roads for transporting materials, lack of qualified resources, the uniqueness of this project on the European continent – at the end of 1927 the compressor station was completed. It is important to mention that the team of workers who built the compressor station (exclusively the technological plant of the station, without the compressor assembly) was composed of two mechanics and eight workers led by a monteur.

90 years ago, 4 people designed and 17 people built a unique station at the time in Europe.

On 22 January 1928, the first aggregate was commissioned, and on 26 January 1928 – the second. The third aggregate was commissioned on 3 February 1928. The assembly of compressors, their connection to the technological installations of the station, the setting up and testing of compressors was led by a Romanian engineer, a chief monteur from the company Ingersoll Rand and a team of 4 workers.

Today, when Romania will build several compressor stations, it would be useful to aim to move beyond the level from 90 years ago!