Siemens’ Teamcenter and eCl@ss Standard to drive better connected systems

- Support for eCl@ss makes it easier for customers on Siemens’ digital innovation platform to manage supply chain complexity

- Teamcenter amongst the first major product lifecycle management (PLM) providers to support eCl@ss Standard in core PLM

- A standard taxonomy with a single thread for digital data exchange helps create no loss of information in the design and engineering processes that define the digital twin, a critical factor in realizing the digital enterprise vision

Siemens announced on October 29 that the Teamcenter® portfolio, the world’s most widely used product lifecycle management software, will now support the eCl@ss Standard for classification and product description. eCl@ss has established itself internationally over 18 years as the only ISO/IEC-compliant industry standard, and has become the worldwide reference-data standard for the classification and unambiguous description of products and services. Supporting a standard classification system can allow Teamcenter users to standardize design, procurement, storage, production, and distribution activities in and between companies – across sectors, countries and languages. This standardized data exchange helps improve the quality of data, simplifies the procurement process and reduces customer costs through economical and efficient integration of PLM product data into customer supplier relationship management (SRM) and customer relationship management (CRM) systems. Siemens PLM Software is one of the first major PLM providers to support the eCl@ss standard in a core PLM technology.

“A common ‘language’ is a key success factor for digitalization and can help to minimize mistakes in information exchange with our customers and suppliers,” said Robert Jung, Head of Intelligent Data Logistics Program for Siemens AG. “Teamcenter support for eCl@ss information structures helps offer multiple productivity advantages within our processes. We will not only be able to maintain and deliver product information hosted in Teamcenter following international standards, but also create a standard structure to import information about components on the manufacturing side.”

In the current PLM environment, customers determine their unique taxonomy and classes, which allows for maximum flexibility and the ability to classify almost anything, including parts, documents and processes. While flexible, this open system creates data in diverse formats, leading to loss of information during translation, disconnected and inefficient systems, and ultimately to higher costs and lower quality. Using eCl@ss can streamline this business data exchange by helping customers and suppliers speak the same language. This is particularly important in complex supply chains where business partners need the ability to exchange the same information, tagged in the same way, throughout the added value chain of supply chain management (SCM), PLM and CRM systems. Detailed specific components, transferred via eCl@ss-based data exchange, can help ensure simulations more accurately model the physical products as the digital twin is defined and validated throughout the product lifecycle. Using an integrated system on a single standard is a critical piece of realizing the holistic digital enterprise vision.

“As one of the first PLM systems to support eCl@ss for digital data exchange, Teamcenter can help streamline data exchange scenarios through the value chain, ultimately creating a more robust digital twin,” said Joe Bohman, Senior Vice President of Lifecycle Collaboration Software for Siemens PLM Software. “All Teamcenter users can benefit from our new classification engine, which not only powers eCl@ss but offers increased flexibility and performance across the board. We look forward to helping our customers leverage the combined potential of eCl@ss and Teamcenter to drive better connected systems.”

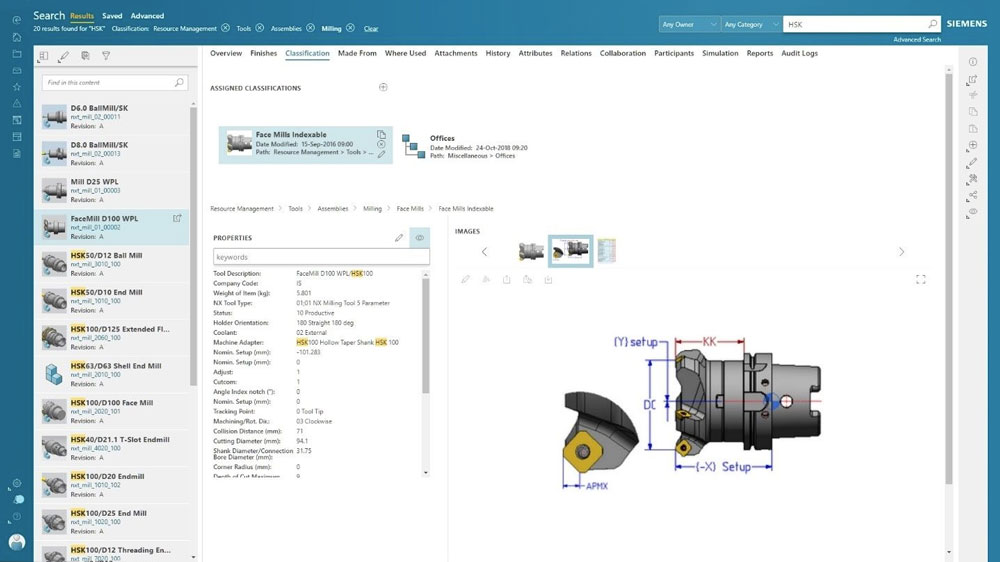

Teamcenter will continue to support both the traditional and new eCl@ss classification systems within the new engine, Teamcenter for eCl@ss Data Management, and can help seamlessly migrate data to the new system as customers are ready. Using this feature within Active Workspace for Teamcenter®software can provide enhanced usability, flexibility and can allow customers to jump start using eCl@ss classification hierarchy. Teamcenter for eCl@ss Data Management in Active Workspace is scheduled for availability in late Spring 2019.

About Siemens PLM Software

Siemens PLM Software, a business unit of the Siemens Digital Factory Division, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, Siemens PLM Software works with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood.