Innovative Technologies for Drilling and Completion in Central Europe

Dosco PetroServices is partnering with Geopro Oilfield Technology Inc to introduce innovative technologies for drilling and completion operations in Central Europe. Geopro’s technologies focus entirely on improving operational efficiency by reducing risk.

Geopro Oilfield Technology’s focus over the years has been on improving efficiency in the well construction process, thereby reducing carbon emissions, and increasing viable proven reserves by facilitating the drilling of complex and challenging wells. Geopro tackles efficiencies across the entire well delivery process by minimizing risks associated while on-bottom drilling with the REACTv™ Sub and flat times, when running tubulars. With a true ultra-low friction centraliser, the GeoGLIDER XTREME, an ultra-high speed, infinitely customizable hydraulically actuated reamer shoe system the GeoproHYDRA, the GeoMole static reamer shoe and the GRS360™ ratcheting mechanical reamer shoe system.

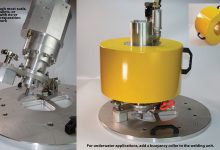

GeoproHYDRA™ nGX – Ultra-High Speed Rotational Reamer Shoes

The GeoproHYDRATM, currently in its 9th generation called the nGX2, is a versatile, robust, infinitely customizable, and scalable reamer shoe system offering operational power at even lower flow regimes, compatibility, and tolerance to a wide range of fluid slurries (including fibrous LCM), high solids content and its customizability enables better ECD management to ensure safe and efficient operations.

The GeoproHYDRATM nGX2 is available as a drillable or non-drillable option. For the drillable options, the standard tool has all internal Aluminium FASTDrill™ optimized components to facilitate quicker drill out times. This includes the entire drive system and nose cone parts with drill-through time between 50 and 70 minutes depending on tool configuration. The RAPID QuickDrill variant has all composite internals that can be drilled out in as low as 30 minutes regardless of tool configuration.

All variants come with entire tool rotation, optimized high-speed cutting structure on the body of the tool (as well as on the nose for the non-drillable option), continuous operation during cementing and field proven bearing pack capable of over 50 million revolutions.

GeoMOLE™ Static Reamer Shoes

The GeoMOLE™ is a static reamer shoe. Utilising the exact same cutting structure of the GeoproHYDRA™, the GeoMOLE on the other hand requires string rotation from surface. It’s cutting structure is made entirely of Tungsten Carbide Inserts (TCIs) to reduce friction rather than PDC cutters. Also, TCIs are less susceptible to sharp variations in temperature and less likely to sidetrack by undercutting the borehole compared to PDC. This is available in drillable and non-drillable variants as well as with free-rotating composite noses.

GRS360™ – Mechanical Rotating Reamer Shoes

The GRS360™ is a mechanical rotating reamer shoe capable of up to 5x (1800°) circumferential rotational cycles with each full reciprocation of the tool. Non-drillable tools come standard with a full laden of tungsten carbide inserts around and on the eccentric nose and usually spring enabled, providing a constant force of up to 5 kips (depending on design), right against the nose mandrel. Drillable options come with guide pins fitted with a rounded ball tip to improve friction as the mandrel telescopes outwards and inwards with reciprocation.

GeoGLIDER® XTREME LITE UltraLow Friction Centralisers

GeoGLIDER® XTREME LITE centralizers are made from glass fibre reinforced resin and were designed from the borehole upwards, based on results from Geopro’s successful experiences with tubular deployment in Extended Reach Wells, where success was based on maintaining fine lines for frictional losses to stay within critical success envelopes.

GeoGLIDER® XTREME LITE centralizers are arguably the best centralizers in the market today. They are the slickest and deliver industry leading friction factors between 0.05 and 0.16, making them ideal for all wellbores where weight transfer to the shoe is a requirement.

It is the only centralizer that has friction reduction inherent in the design. With the smallest footprint of 5 in2, no sharp edges and axial offset blades create constantly resolving forces about its three-bladed profile resulting in a system with 30% higher flow-by area and the smallest effective blade diameter thus ensuring the string can be worked through restrictions and tight spots a lot easier than any other product available in the market, without jeopardizing stand-off.

REACTv™ Sub – A True Drilling Assurance System

The REACTv Sub is a purpose-built drilling assurance system for reducing drilling risk associated with on-bottom drilling and improving drilling efficiency. Its benefits include:

- Better weight transfer to the bit

- Less hole rugosity

- Hole cleaning

- Lower drill string torque

- Borehole enlargement

- Shocks and vibration mitigation and reduction

- Stuck pipe prevention

- Reduction in unnecessary wiper trips

- Reduction/elimination of backreaming

The REACTv Sub is based on the inverse Moineau system like a positive displacement motor, however, in this instance the stator is allowed to rotate while the conventional rotor is held static along with the rest of the drill string. It affords the drilling team the ability to respond to hole problems such as tight spots, swelling shales or wellbore collapse quickly, without the need to significantly vary surface operating parameters.

The REACTv Sub is fluid activated so it can be activated without rotating the string. Additional torque can be transferred to the tool by rotating the drill string, if required.

Case Histories and Technology Adoption

Geopro technologies have been deployed across the globe. Thailand, Malaysia, India and Indonesia in South-East Asia; Nigeria and Morocco in Africa; Oman, Kuwait and Saudi Arabia (Middle East); and USA, Colombia and Mexico (in the Americas).