Overcome Drilling Difficulties and Increase Rate of Penetration by Over 30% When Using a New Generation of Stabilizers & Reamers

For the longest time spiral blade stabilizers have been running the show when it comes to stabilizing the drill string. With its simple design and low cost of running it has always been a solid option. But conventional spiral blade stabilizers come with some major disadvantages.

Spiral blade stabilizers cause quite some negative effects, such as:

- The sharp edges increase torque and drag and can cause mud cake

- The conventional stab design hinders the flow of cuttings and fluids around the tool

- The spiral profile increases tendency to balling up, resulting in a higher ECD, surge and swab, which can cause stuck-pipe incidents

- It often causes an increase in vibration levels and hole spiralling, leading to loss of energy, a decreased ROP and MWD/LWD failures.

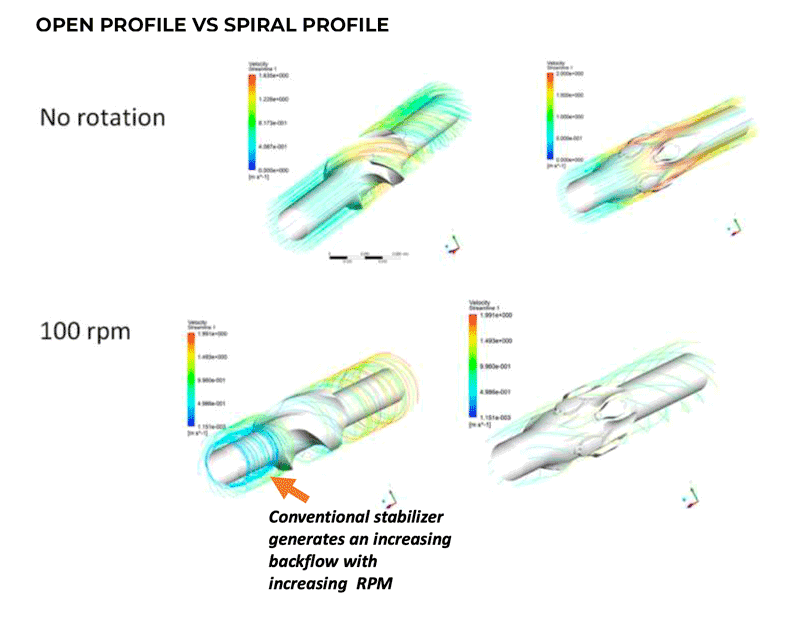

Open profile vs spiral profile

The new generation of stabilizers shies away from the spiral profile and introduces an open Hydrodynamic profile, which is optimal for the transportation of cuttings. This open profile also takes out the sharp edges and offers a smooth dome-shaped geometry of the stabilizer blades towards a more efficient interaction with the wellbore drilled formation. This leads to reduced friction and less torque compared to conventional stabilizers, which in turn, contributes to lower levels of stick slip and vibration. The longer overall crown length, from the tip of the top row to that on the opposite side of the bottom row, offers more stability, favouring lower levels of downhole vibration.

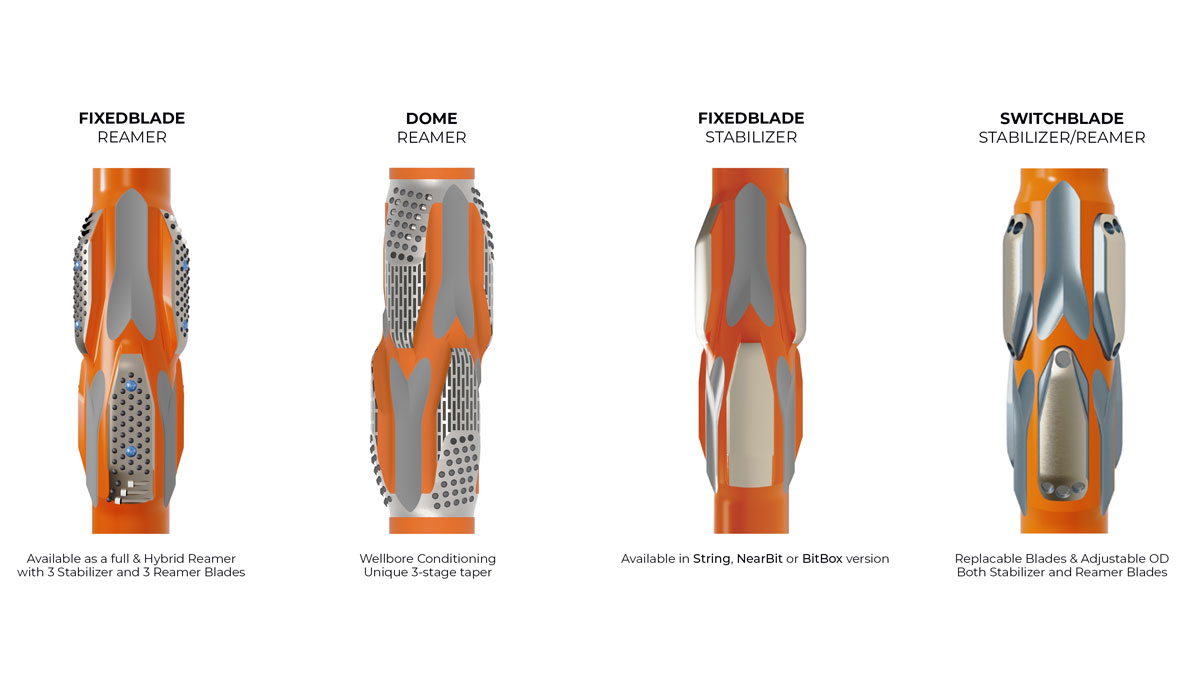

A complete product line has been developed that takes advantage of a Hydrodynamic profile: Fixedblade Reamer, Fixedblade, Switchblade, Dome Reamer, Fixedblade with Flute Profile or Recess Profile.

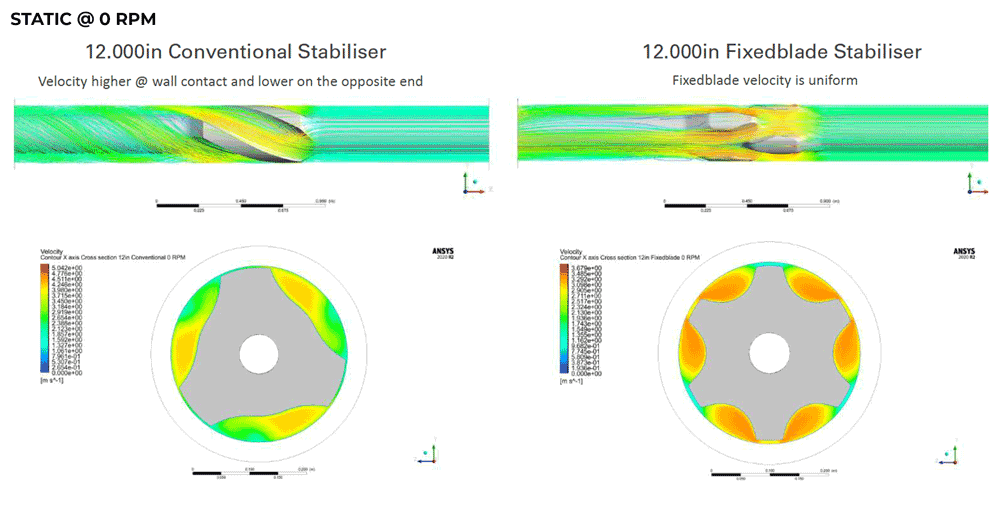

Flow dynamics

This Hydrodynamic profile sees its maximum effect when looking at the flow dynamics while rotating. Conventional stabilizers generate an increasing backflow when the RPM’s are increased. The Hydrodynamic profile shows a more streamlined backflow, resulting in less torque, drag and transporting cuttings and fluids more effectively which increases your ROP and reduces wear on BHAs components.

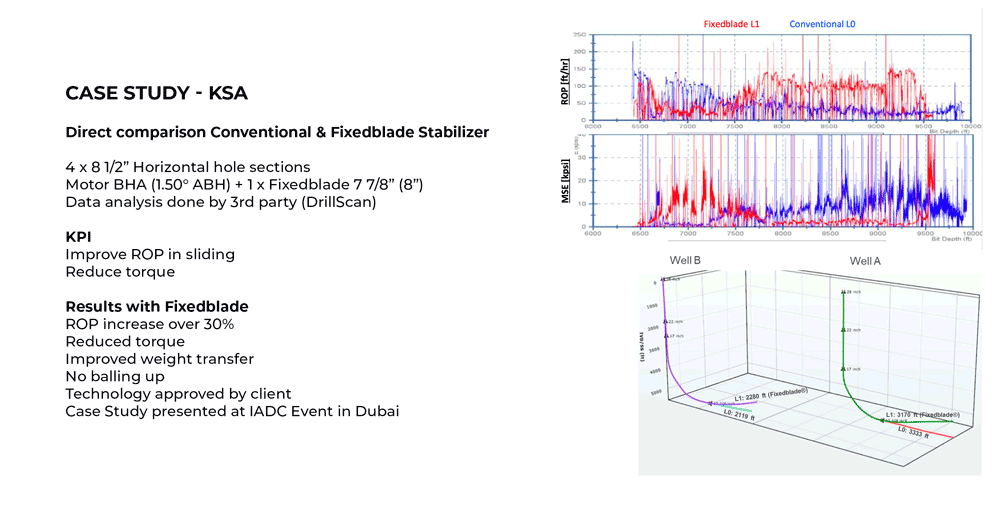

Improved ROP, Torque, Vibration, and Stick Slip

Multiple cases studies have been done on the direct comparison between conventional vs. Fixedblade stabilizers, and they show promising results. The ROP increases over 30% while reducing torque, vibration, stick slip, whilst improving weight transfer and showing no signs of balling up.

Dosco PetroServices is the strategic partner for ED-Projects in Romania. If you would like to receive more information, please get in touch with a Dosco representative.