World’s First Fossil-free Steel Components in Automotive Safety Products

Autoliv, the worldwide leader in automotive safety systems, and global steel company SSAB, have initiated a collaboration to research and develop fossil-free steel components for automotive safety products, such as airbags and seatbelts.

The collaboration enables Autoliv to be in the forefront in producing automotive safety products with fossil-free steel from SSAB. A new process aims to replace coking coal, traditionally needed for ore-based steelmaking, with hydrogen. The result will be unique: the world’s first fossil-free steelmaking technology, with no carbon footprint.

Autoliv leads the way with ambitious climate targets

“As the first automotive safety supplier, we are committed to becoming carbon neutral in our own operations by 2030 and furthermore aim for net-zero emissions across our supply chain by 2040. This means reducing our carbon emissions through use of renewable electricity in our own and supplier operations, improving energy and materials efficiency and adopting low carbon logistics and low carbon materials. We are now turning our commitment into action and are well-positioned to continue supporting our customers and partners to reach their sustainability goals. Gradually switching to fossil-free steel in our products is an important step towards achieving our climate targets,” says Mikael Bratt, President and CEO of Autoliv.

“We are looking forward to working with Autoliv and to start the process of research and development of innovative fossil-free steel components for their automotive safety products. We are initiating a number of pilot projects together with Autoliv with the aim to reduce climate impact and strengthen competitiveness,” says Martin Lindqvist, President and CEO of SSAB.

A uniquely fossil-free value chain for iron and steelmaking

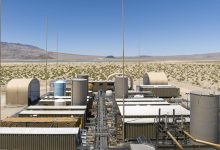

In 2016, SSAB, LKAB and Vattenfall joined forces to create HYBRIT.

In 2026, SSAB plans to supply the market with fossil-free steel at a commercial scale after a conversion of its Oxelösund blast furnaces into an electric arc furnace and by using iron made with the HYBRIT technology, which replaces coking coal traditionally needed for iron ore-based steelmaking, with fossil-free electricity and hydrogen. This process virtually eliminates carbon dioxide-emissions in steel production. A pilot plant has already produced smaller volumes of iron using hydrogen. On August 18, SSAB showcased the first steel made of hydrogen reduced iron.