Flowserve Expands its RedRaven IoT Solutions for Valves

Flowserve Corporation, a leading provider of flow control products and services for the global infrastructure markets, has expanded its revolutionary industrial IoT service suite, RedRaven – giving companies even greater insight into the performance of their flow control systems by now offering valve-specific capabilities.

With RedRaven IoT solutions available for both pumps and valves, companies can now monitor valve health to proactively identify and address issues before they cause downtime.

Using multiple connectivity options, RedRaven monitors valve performance trends and alerts users when a valve deviates from normal operating conditions. The RedRaven solution is also manufacturer agnostic and works with most plant’s existing digital positioners – meaning it can monitor hundreds of valves across large industrial facilities without expensive infrastructure, installation and/or additional hardware costs.

“We understand that companies around the world are looking for ways to streamline their operations while balancing the challenges associated with aging equipment, complex datasets, and limited equipment-specific expertise and maintenance personnel,” said Tauseef Salma, Vice President, Global Marketing & Technology. “With RedRaven’s capabilities for both pump and valve equipment now, companies can have greater insight into their holistic flow control system while also better meeting their sustainability goals through increased energy efficiency and uptime.”

RedRaven communicates both the health and performance of valves throughout a facility. Equipped with data-enabled insights across multiple locations, users can make significant improvements to enhance equipment efficiency and reduce associated carbon emissions.

RedRaven IoT valve services also provide insight monitoring, which gives users a detailed view of valve health through an online cloud portal and offers users greater access to experienced Flowserve technical and service professionals. With RedRaven’s expanded capabilities and increased span of monitoring for both pump and valve equipment, companies can have a more comprehensive view of their flow control system, helping to further increase uptime, lower maintenance costs, and improve safety and reliability.

Taking fluid motion IoT to new heights

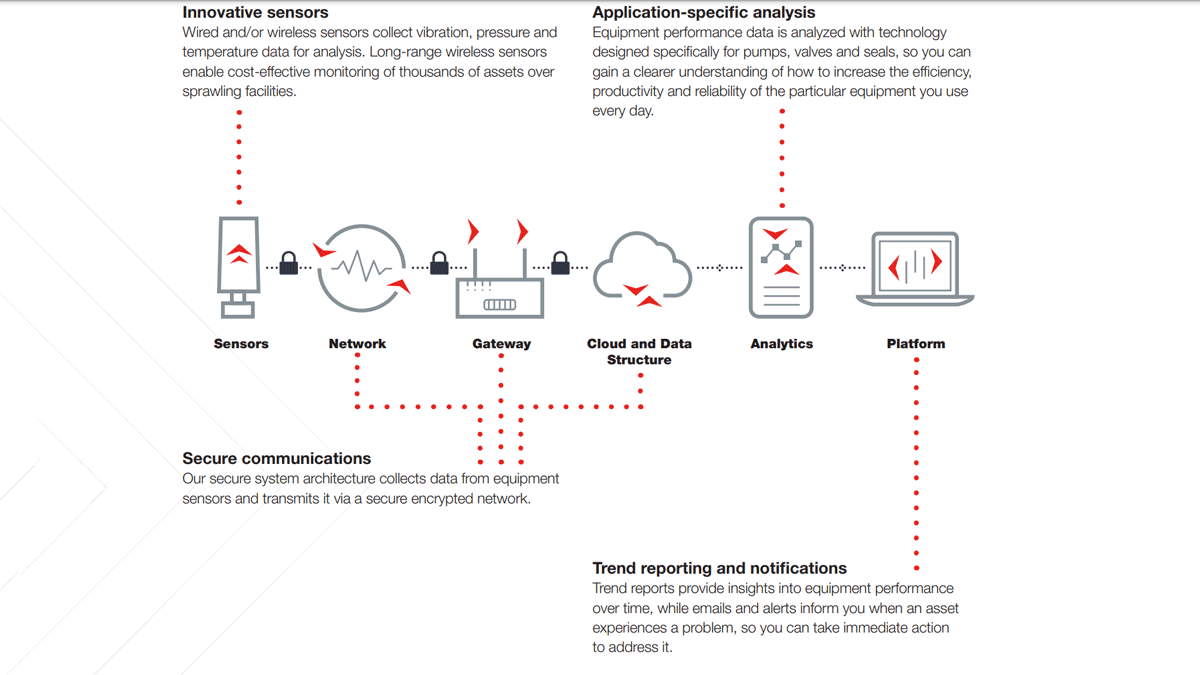

RedRaven is Flowserve complete end-to-end IoT solution for the industrial space— a turn-key offering from sensors to cloud architecture, analytics and condition monitoring and predictive analytics services — so companies can reliably and cost-effectively monitor thousands of assets over sprawling facilities.

The Flowserve RedRaven platform includes a suite of solutions, including equipment sensors, secure communication, performance analytics and trend reporting tools. It also includes a range of offerings that can be customized to meet companies’ plants unique needs.

Options include condition monitoring services, which allow to capture asset performance data for analysis, and predictive monitoring capabilities, which apply data analysis software and algorithms to identify and diagnose equipment problems.

RedRaven IoT Technology and Services Platform benefits

- Predict equipment behavior. Respond to problems quickly and minimize disruptions and downtime.

Use trend analysis data to make informed decisions about plant-wide reliability improvements.

- Refocus maintenance efforts. Focus on those assets that require attention, thus avoiding unplanned downtime and optimizing maintenance efforts so you spend less time evaluating healthy equipment.

- Enhance equipment efficiency. By knowing where all companies’ assets are on their respective pump operating curve, they can be optimized for maximum efficiency.

- Reduce costs. Reduce total cost of ownership by easily recognizing when to schedule equipment maintenance and reducing spare part inventories.

- Improve safety. By alerting technicians to a problem and what the failure mode might be, the RedRaven platform helps them respond to performance issues quickly, limiting the time they spend in hazardous environments.