Ground-breaking Ebflow Technology to Reduce Production Time of SMRs

Coinciding with British Science Week, Cambridge Vacuum Engineering (CVE) announced a major breakthrough in the world of welding, which is set to reshape the future of nuclear production worldwide. Working with Sheffield Forgemasters, CVE’s Ebflow technology was able to cut the amount of time needed to weld a small modular reactor (SMR) pressure vessel demonstrator from more than a year to less than 24 hours. This news comes the week after the Chancellor – Jeremy Hunt – announced the continuation of the development of small modular reactor nuclear technology in the UK.

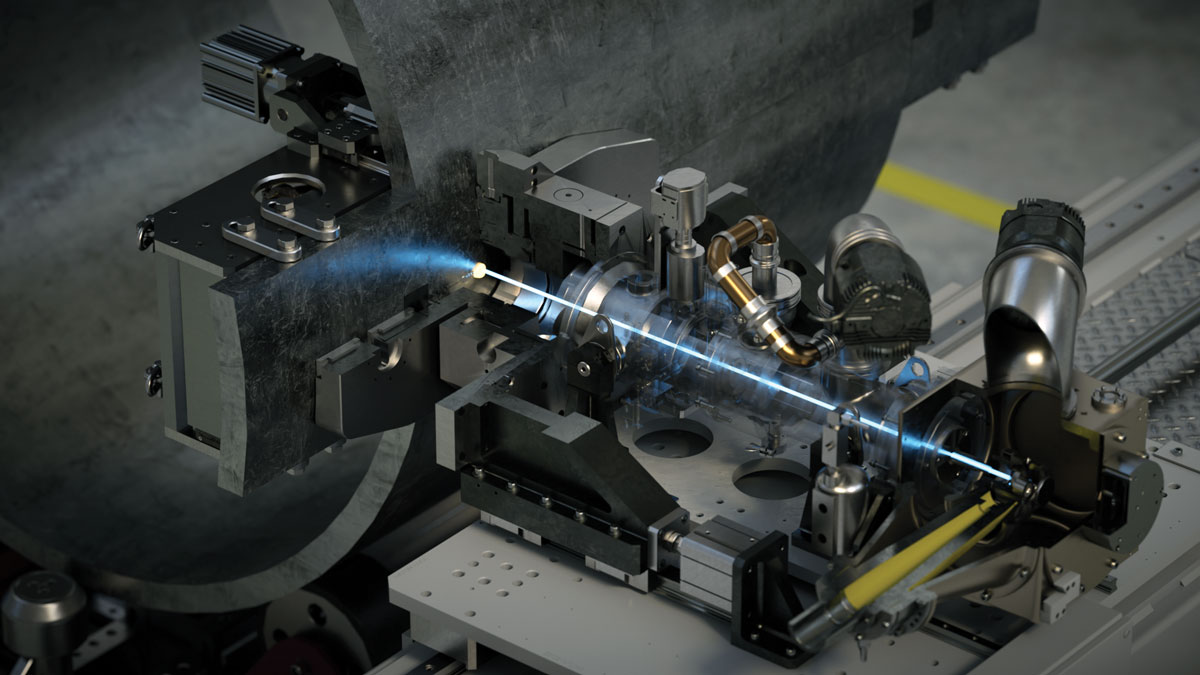

An advanced electron beam (EB) welding technology, developed by Cambridge Vacuum Engineering (CVE) has the potential to transform the speed at which small nuclear power stations can be built. In a trial conducted by Sheffield Forgemasters, Cambridge Vacuum Engineering’s Ebflow technology was deployed to cut the amount of time needed to weld a small modular reactor (SMR) pressure vessel demonstrator from more than a year to less than 24 hours – a move that could help reshape the future of nuclear reactor production worldwide and bridge the gap in the UK’s energy market.

As part of a government-funded project, Sheffield Forgemasters incorporated Ebflow, operating under local vacuum, into a bespoke, large-scale EB facility at its Brightside Lane site to complete four thick nuclear grade welds on vessels with a diameter of three meters and a wall thickness of 200mm. As well as reducing welding time by an astounding 99%, Ebflow also delivered the superior quality and precision of welds needed to ensure SMRs operate safely – setting a new standard for weld-joining thick-walled components.

Ebflow is a highly advanced fusion welding process with applications across a wide range of industries from oil and gas to nuclear power generation to ship building and more. The technology utilises a focused beam of high-velocity electrons to join metal components together. The main difference to traditional welding methods is that no third-party material is introduced to make the join. This technique enables unparalleled levels of accuracy and efficiency, making it ideal for the intricate welding requirements of primary components used in mission-critical energy applications – including mini nuclear reactors.

“Our partnership with Sheffield Forgemasters demonstrates the power of Ebflow and proves – beyond doubt – the benefits it can deliver when it comes to driving sustainable advancements in the energy sector. We all know the clock is ticking when it comes to climate change. As more governments worldwide sign up to net zero emissions by 2050, the energy industry must embrace technologies – like Ebflow – that can help speed up the deployment of low carbon energy production,” Bob Nicolson, Managing Director at CVE, said.

Sheffield Forgemasters is the only company in the UK with the capability to manufacture the large forgings required for SMRs, and now – thanks to Ebflow – it has years of developmental lead on global competitors in welding thick-walled assemblies.

“The implication of industrialised Electron Beam Welding technology within the nuclear industry is monumental, potentially taking high-cost welding processes out of the equation,” Dr Michael Blackmore, Senior Development Engineer and Project Lead at Sheffield Forgemasters, added.

“We are delighted to have reached a significant milestone in assembling a nuclear vessel demonstrator, using electron beam welding for the first time at this scale, with 100 per cent success and no defects,” Professor Jesus Talamantes-Silva, Research, Design and Technology Director at Sheffield Forgemasters, noted.

Dr Jacob Pope, Development Engineer and LEBW machine tool installation lead at Sheffield Forgemasters, in his turn, mentioned: “We thank the Government’s Department for Energy Security and Net Zero for enabling the project through its Nuclear Innovation Program. We also thank our esteemed partner, Cambridge Vacuum Engineering, for their invaluable support throughout this endeavour. Their remote and on-site assistance played an instrumental role in the success of this project.”

Ebflow is the result of years of research and development by specialists at CVE, which is headquartered in Cambridge, UK and has regional offices in Beijing, China and Massachusetts, USA, as well as a global network of agents.

About Cambridge Vacuum Engineering

Aquasium Technology Ltd, trading as Cambridge Vacuum Engineering (CVE), design and build process solutions and has more than 60 years’ experience manufacturing electron beam (EB) systems in a range of industrial sectors including aerospace, nuclear, automotive, oil and gas, and sensors. The company exports around 95% of its systems with primary markets in USA, China, India, and Europe. CVE’s range of EB welding equipment includes systems ranging from 50-200kV with beam powers up to 100kW. CVE has a team of designers and engineers to enable them to design and build bespoke manufacturing equipment to meet their customer’s requirements.

About Ebflow

Ebflow is a local vacuum electron beam welding system, which can be readily transported and operated on-site and applied to structures significantly larger than those that can be accommodated in a vacuum chamber. Ebflow eliminates the need for a vacuum chamber through a local, coarse vacuum, which is established and maintained only where it is needed. Ebflow facilitates very high joint completion rates in thick-section metals and is 20-30 times faster than conventional submerged arc welding: achieving 200mm per minute in 150mm thick steel – allowing for the fastest thick-section rates ever.

About Sheffield Forgemasters

Sheffield Forgemasters specialises in the design and manufacture of high-integrity forgings and castings for the world’s most complex engineering challenges.

The company operates a fully integrated end-to-end manufacturing process, including steel making, forge, foundry, machining, and testing, from a single site in Sheffield.

Some of the largest bespoke engineered steel products in the world are produced with capacity for castings of up to 350 tonnes and forgings of up to 200 tonnes finished weight.

Global markets include Defence, Civil Nuclear, Offshore, Power Generation, Renewables, Steel Plant, Steel Processing and Ingot & Bar.

The company was acquired in August 2021 by the Ministry of Defence who intend to make significant investments to re-capitalise defence-critical plant and equipment on site.