Keep IT Mobile Implementing NFC Technology in Oil & Gas

Keep IT Mobile (KIM), a 100% Romanian company, established in 2012 by Vicentiu Corbu, who left a job in multinational companies to become an entrepreneur, in 2015 launched the first global demonstration of the NFC (Near Field Communication) technology applied in the oil & gas sector. It was implemented subsequently, for the first time in our country, within a refinery in Romania.

Keep IT Mobile, which currently develops software solutions that help companies streamline their technological flows and, implicitly, digitize, has obtained the Seal of Excellence distinction within the Horizon 2020 program of the European Commission, phase 2, being the first company in Romania to obtain this quality label for the development of the NFC technology.

“We can provide any company on the territory of Romania with digitization solutions like those produced by giants in the field, with the advantage that we customize them, and they have lower prices. As background, we come from multinational companies where most of the experience was gained with international software companies focused on aviation, meteorology, logistics etc. We are now using a new technology for the traceability of activities, human resources, and physical items in general. The technology is called NFC and we all have it integrated in the mobile phones, being known for the mobile parts, except we applied it for other purposes. Basically, we attach such NFC chips on equipment, tools, locations, following that with a simple touch with the mobile phone we have all the information in that place. We provide personalized solutions for companies, as you go to the tailor for a custom-made suit,” says Vicentiu Corbu, founder and CEO of Keep IT Mobile.

In the last seven years, Keep IT Mobile has developed (with a team consisting of 10 employees plus collaborators) a number of software solutions covering the need for digitization for a large part of industries, having clients such as Electroalfa Botosani, Comelf Bistrita, Pyronova (from Slovakia, with subsidiaries in the Czech Republic, Hungary, Germany, Poland, Russia), Severnav, Vard, 24 Ianuarie Ploiesti or Daas International shipyards.

“We are currently delivering these solutions at a minimum cost for any company on the territory of Romania that wants digitization of operational flows but does not afford major investments in this moment of crisis. Therefore, we come up with a cost starting with EUR 100/month, aimed only at covering the operational expenses with the implementation/support of the mentioned technical solution. In this way, any company can be digitized at a minimum cost,” mentions Vicentiu Corbu.

Field Maintenance System

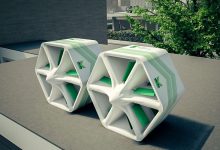

Keep IT Mobile has introduced, as a national premiere, a management system for firefighting equipment in a refinery, in collaboration with another company, the solution being named Field Maintenance System. Its aim is to register interventions made at the existing firefighting equipment in the field, with the help of mobile technologies.

The operation is carried out in three steps. First, the firefighting equipment is identified, then an NFC tag is placed on this equipment, the association of information necessary for the system taking place: extinguisher type, expiration date, location, and responsible person.

In the third stage, the following interventions take place: entering operations (verification, upload), entering the parts/consumables used, counting the duration of the intervention, extension of the validity period, taking over electronic signatures to validate the intervention, finalizing and updating data in the system.

The advantages consist of: performing real-time checks on refinery equipment; traceability for used spare parts; automatic generation of estimates/reports and (optionally) their printing using mobile printers; collecting data from the field, in a mobile manner, respectively centralizing in a relational database; eliminating human error through the use of NFC communication technologies as well as barcode reading technologies.

Problem worth solving

Good maintenance management is important for the companies’ cost control. As companies go in for automation to become more competitive, they increasingly rely on equipment to produce a greater percentage of their output. Equipment must be kept in reliable condition without costly work stoppage and down time due to repairs if the company is to remain productive and competitive. Beyond the cost of idle equipment and idle labor that can result from a breakdown, there is a danger of permanently losing market share to companies that are more reliable. Maintenance function can help prevent such as occurrence.

Organizations like airlines and oil refineries have huge investments in equipment. Equipment failure would be disastrous for such companies and ineffective maintenance practices can also result in unscheduled downtime with huge costs; for instance, for global petroleum refiners such unscheduled downtime costs on average an additional USD 60 billion per year in operating costs.

They need proper preventive maintenance to keep the equipment in good condition.

Today’s maintenance management systems offer the possibility to introduce in real-time the data collected from the field, but the way of doing that is sometimes too slow for the operative technicians.

Keep IT Mobile solution

KIM CMMS uses the Near Field Communications (NFC) technology to identify and track field operations of industrial assets through NFC tags/microchips.

By tapping a smartphone against the NFC tag, users are taken directly to the asset record in the CMMS, where they can log their issue. Moreover, KIM CMMS uses NFC technology to provide proof of presence for safety-related work orders. The tapping motion is recorded digitally, proving the technician was physically at the asset when the work order was completed. An important by-product is that NFC is already available in the majority of mobile phones which makes KIM CMMS less expensive than competing solutions, such as RFID readers or barcode scanners and fully benefiting from the user friendly and intuitive interface smartphones offer.

KIM CMMS therefore responds to the need for a mobile tool to manage in a lucrative and cost-effective way the equipment maintenance operations in a wide range of industries, by providing an affordable and exceptionally reliable/secure software solution.

Bellow you may see the advantages and disadvantages of the NFC technology.

Target market

After the first trials with OMV Petrom in 2014, a feasibility study was performed to research the market needs and the market potential of the KIM CMMS technology. KIM’s team has made the following realistic conclusions, reflecting the user/market needs:

- Intuitive and easy to use mobile solution to cope with the operational flow in industry

CMMS Software tools for industrial maintenance already exist, but KIM CMMS provides a mobile solution which focuses on usability in combination with NFC technology benefits.

KIM CMMS meets users’ needs thanks to the native app solution built for Android OS, which is easy to use, especially by non-tech savvy users. Secondly, the team behind KIM CMMS has successfully detected the need for a mobile tool to collect and register data on-the-go.

KIM CMMS provides the first mobile tool to keep track of industrial assets from the “palm of your hand”, built to be used also in isolated areas (such as offshore platforms).

- Affordable mobile system

Existing mobile CMMS solutions are mainly created by specific software companies with significant experience and market share in smart industrial maintenance (such as IBM, SAP) but for higher budgets, minimum EUR 50.000. On the other hand, the IBM and SAP solutions offer ‘built in’ mobile access to their enterprise asset management (EAM) platforms, so the users need to purchase the entire platform in order to use the mobile component. KIM CMMS meets the users’ needs by offering a premium mobile solution at a cost of EUR 2000 per year or EUR 15000 (on premise version) to disrupt the custom markets by providing the same users with a powerful tool to meet their operational needs.

- Flexible and fully customizable solution

KIM learned from the feasibility analysis that users need a fully customizable solution, which can be easily integrated with existing ERP platforms, and therefore they built it into the KIM CMMS’ architecture. Their product can work either autonomously or substitute the mobile component of competing solutions: Maximo Mobile Asset Manager or SAP Enterprise Asset Management. Additionally, the application allows self-generation of interfaces to meet the needs of the operators in the field. With KIM’s system a wide number of variations can be made to respond to companies’ needs in 5 industrial sectors: Manufacturing, Energy, Oil & Gas, HVAC, Facility management. KIM also learned that customizable end result has enormous commercial value. Other competitors such as SAP or IBM are using proprietary development platforms, limiting the possibilities of customizations by other companies outside their scope.

- NFC technology

NFC is currently rated in top 5 digital market trends for its application in digital payments (‘mobile wallets’) but hardly exploited for its potential in the industrial sectors. KIM concluded feasibility study that B2B users intend to experience the benefits provided by the NFC technology (accuracy, speed, affordability) in tracking assets management. In conclusion, KIM has set up its Unique Selling Proposition as follows:

- KIM CMMS is a 100% customizable and affordable mobile solution for industrial use, integrating the benefits of the NFC technologies.

- KIM CMMS is introduced as an extremely cost-effective solution (considering its superior features), able to disrupt the digital ICT market, and its sales costs are more than 50% lower than competing solutions, which, in addition to the innovative technology and unique features, is one of KIM CMMS’s Unique Selling Points (USP) that differentiates the solution from its competitors. USP help consumers by saving them time when they are considering buying a product. By stating clearly why KIM CMMS is novel and different, it stands out from competitors by being Better, Smarter and Cost-effective.

- KIM CMMS targets mainly 2 different market segments and rolls out a strategy that addresses the needs of these segments. KIM CMMS targets business users (B2B) such as large state-owned or independent industrial companies, service providers and SMEs in the industrial supply chain with more customized solutions, while trying to reach as many individual users of the application as possible: professionals in industry (maintenance managers, operators, field coordinators, operations directors etc.).

Fortune Business Insights in a new study, titled ‘GLOBAL INTERNET OF THINGS MARKET: GLOBAL INDUSTRY ANALYSIS, INSIGHTS AND FORECAST, 2019-2026’ provides key insights into trends prevailing in the market. IoT technology helps exchange information between machines and devices. It plays a crucial role for some organizations by offering digital transformations and upgrading their existing processes to create new business models.

Key facts

Keep IT Mobile solution is based in Ploiesti, one of the most important industrial cities in Romania, which concentrates 70% of the national Oil & Gas industry. The strategic location of the company and the partnerships with the biggest O&G operators in the area allows the company to develop and integrate its business flows with the O&G industry maintenance flows and deliver successful software products for environments with explosion risk (refineries & filling stations). It is worth mentioning that KIM has successfully performed a pilot field trial of the KIM CMMS in the facilities of OMV Petrom in Ploiești, which was also the world’s first application of NFC technology in an oil refinery.

The company has been working closely with companies in several Industrial sectors for the last five years, developing innovative solutions to solve operational problems and increase efficiency. KIM’s track record for successful software product development is evident from more than 7 internationally marketed products that use the company’s proprietary technologies for the following market sectors: Energy, Oil & Gas, Manufacturing, Retail and Logistics.

Opportunity

General Electric estimates that a 1% improvement in equipment maintenance efficiency in five global industries – Oil and Gas, Power Generation, Health Care, Aviation and Rail could add up to USD 276 billion over 15 years. By monitoring equipment better and predicting other potential network problems in Power Generation industry, by using mobile equipment more efficiently in Health Care, by cutting fuel and operating costs and making equipment more available and productive in Oil & Gas and by using smarter engines that inform airplane crews when maintenance is needed, global industrial organizations can improve productivity and significantly reduce maintenance costs.

Also, asset-intensive organizations such as airlines and oil refineries can be disastrous for workers’ safety and highly costly. For instance, one single oil pump failure can cost USD 100.000 to USD 300.000 a day in lost production and overall, for petroleum global refiners such unscheduled downtime costs on average an additional USD 60 billion per year in operating costs.

It is clear that global industry organizations need proper and cost-effective preventive maintenance to keep the equipment in good condition and optimize maintenance operations.

Today, Industrial Internet of Things (IIoT) is proliferating due to its potential to streamline and deliver greater time and cost savings to a wide range of industries. Cisco predicts the global IoT market will be USD 14.4T by 2022. IoT in manufacturing market size is estimated to grow from USD 4.11B in 2015 to USD 13.49B by 2020, attaining a CAGR of 26.9%. The IoT makes it possible to reduce-and potentially eliminate-unexpected maintenance costs by sensing and monitoring everything happening within a working device or a smartphone. By some projections, IoT applications could reduce production and lifting costs by more than USD 500 million of a large O&G company with annual production of 270 million barrels.

Innovative smart solution

KIM CMMS, the innovative smart solution developed by Keep It Mobile, responds to the current global need for a mobile and affordable tool to manage in a safe and efficient way the equipment maintenance operations in industrial sectors.

KIM CMMS’s central objective is to disrupt existing traditional solutions for asset maintenance in industry and build smart, connected Industry 4.0 by the industry-wide adoption of IoT technology.

KIM CMMS uses Near Field Communications (NFC) technology to identify and track field operations of industrial assets through NFC tags/microchips and provide proof of presence for safety-related work orders. By tapping a smartphone against the NFC tag, the technicians are taken directly to the asset record in the CMMS where they can log their issue.

NFC is becoming increasingly important within asset tracking, primarily because it offers greater value for money through the availability of low-cost NFC enabled phones and software development. On the other hand, one of the main trends in global mobile app development nowadays is the focus on mobile apps with sensor and processing capabilities. KIM intends to avail of this business opportunity and introduce into the world’s market a product which integrates NFC technologies in the development of a mobile solution for industrial maintenance.

Why Keep IT Mobile?

KIM CMMS’s ambition is clear: disrupting the world mobile application market by being the number one global mobile application in industrial assets maintenance. The novelty of this project is a combination of its mobile/smartphone technology for Industry and the NFC technologies. KIM CMMS project introduces for the first time the NFC technologies for industry use by offering an intuitive tool with focus on preventive maintenance management.

As the platform works on a SaaS business model and is easily customizable for different types of industries, all kind of business customers, partners, end-users and other stakeholders can benefit from it, including large companies and SMEs working in the supply chain, experts and non-experts. These features make KIM CMMS a powerful tool that will enable other European companies innovate in their maintenance operations and become more competitive. Due to its customizable nature, KIM CMMS can apply across key industries with global reach, such as Manufacturing, Energy (Oil & Gas, Electricity and Wind Energy), Installations (HVAC, Firefighting), Facility management (maintenance & repair of buildings equipment). A synthetic overview of the key technical features differentiating the KIM CMMS technology from the state-of-the-art and the product’s advantages which will give a competitive market edge are provided bellow.

- Industry need: Most CMMS software solutions for industry are lacking mobility and are distributed at a premium price.

KIM response: KIM CMMS software application for industry is designed to be viewed with any type of NFC enabled smartphones. KIM will therefore commercialize the product as a turnkey solution together with smartphones, at low cost.

- Industry need: Many mobile asset trackers use RFID or Barcode technology. However, portable RFID readers are expensive, which makes customization of supporting software not feasible and the scan time of barcodes using a smartphone camera is slow and lacking security by comparison with NFC.

KIM response: KIM CMMS uses cutting-edge NFC technology for successful asset tracking of industrial equipment. Superior features of NFC technology over RFID and barcode: reliability, ease of use and improved security features.

- Industry need: Commercially available mobile CMMS applications are usually time consuming when entering data into the system.

KIM response: KIM CMMS uses the latest mobile communication technologies for data transfer and therefore the time for data transfer is reduced by 50% as compared to similar mobile applications. The app uses an intuitive interface to enter data into the system and issue reports.

- Industry need: Currently available mobile CMMS systems have limited functionalities due to technologies used. For example, being only a web interface, it limits the possibility for mobile devices to work in offline mode.

KIM response: KIM CMMS solution is built on a web responsive platform, which can be easily accessed from any device (desktop/smartphone/iPad), and its native application is developed for Android OS, which is highly intuitive and user friendly. The solution is built on a mechanism which automatically generates mobile user interfaces: the user can create the interface it needs for data entry, depending on the operation undertaken.