TGV of the Future

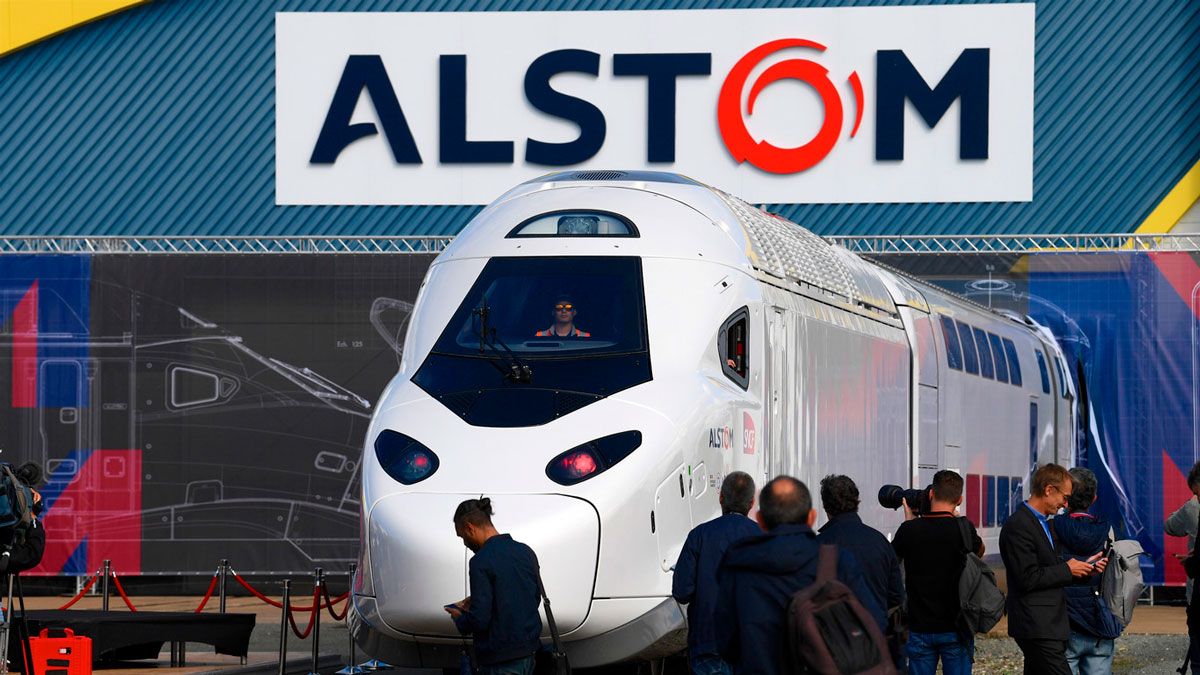

On September 9, Christophe Fanichet (Chairman and CEO of SNCF Voyageurs), Alain Krakovitch (Director of TGV-Intercités), Xavier Ouin (Industrial Director of SNCF Voyageurs) and Jean-Baptiste Eyméoud (President, Alstom France) unveiled the production line of the TGV of the future in Alstom’s La Rochelle workshops, after an operation that brings together the power cars and passenger cars.

The TGV M, which has benefited from the know-how of the best experts at Alstom and the Rolling Stock and TGV-Intercités divisions of SNCF Voyageurs, will run on the national network from 2024.

More capacity, more ecological, more connected, more accessible…

- Unprecedented modularity, which makes it possible to adjust the number of cars as closely as possible to the market’s needs (7, 8 or 9), to quickly transform a 1st class space into a 2nd class space and vice versa, to reconfigure the interior by removing or adding seats, bicycle, or luggage spaces, etc.

- A 20% increase in on-board space, i.e., a possible offer of up to 740 seats compared to the current maximum of 634.

- Ultra-competitive energy efficiency and carbon footprint per passenger: the TGV M’s carbon footprint is the lowest on the market and 97% of the train’s components are recyclable. With a 32% reduction in CO² emissions, the TGV M is fully in line with the SNCF Group’s environmental commitments, as set out in the SNCF Voyageurs ‘Planète Voyages’ programme, which aims to reduce the carbon footprint and energy consumption of all its activities.

- Access to evolving connected services that meet passengers’ needs, such as on-board Wi-Fi, as well as complete information in real time in the various areas of the train.

- A highly ‘communicating’ train set whose sensors continuously transmit thousands of pieces of data enabling the train to be examined in real time from every angle to optimize maintenance and availability,

- Increased on-board accessibility for the benefit of all passengers.

New features, major changes

The new features of the TGV M, as well as its technical specifications, are different from those of the current fleet, leading SNCF Voyageurs to deploy an operating program involving all the group’s players.

Operation

All TGV operating processes need to be modified, whether related to driving, traffic supervision, train preparation in stations, or to parking, depots, and cleaning. This is linked, for example, to the fact that the TGV M will have 9 passenger cars instead of 8 like the current TGVs. Or to the fact that the majority of the interfaces in the driver’s cab have been digitized.

Maintenance

Major investments have been made in the TGV maintenance Technicenters to make their facilities compatible with the TGV M and to install automated maintenance benches that can check several hundred parts of a train in a few seconds.

And in these Technicenters, the new predictive maintenance concepts, based on the use of the thousands of data from the TGV M, promise to bring TGV maintenance into a new era. The technical data will provide clear, reliable, and high value-added information, making it possible to anticipate breakdowns in doors, air conditioning systems and, in general, all the systems that contribute to train operation and passenger comfort.

Network and stations

A detailed analysis of the compatibility of the TGV M with the network and stations is being carried out throughout France. It consists of ensuring that the new train is properly registered at all points on the network and in all stations. This analysis is used to identify the adaptation work that needs to be carried out, the procedures that need to be modified and the changes that need to be made in terms of passenger flow management.

For example, the surveys already carried out in nearly 70 stations show the need to move stop signs to make it easier for drivers to see the signals when the trains are on the platform. This is linked to the nose of the TGV, which has been lengthened to make it more aerodynamic.

Digital

A vast project is underway on digital and information systems. This is important because the TGV M is hyper-connected, and customers’ uses are increasingly oriented towards digital systems. It consists of proposing and implementing appropriate digital solutions and supports to meet customer needs and improve efficiency in all areas.

For example, attendants will have an application that tells them in real time the operating status of all the elements that contribute to the comfort of customers. The WIFI architecture on board the train will comply with the latest 5G standard, to deliver a high-quality service. And various digital applications will be developed in particular to optimize traction energy consumption, by adapting driving instructions in real time to the speed of the train and the profile of the route.

Employees

The arrival of the TGV M will bring about changes in the SNCF’s ‘business processes’. It is therefore essential to pay the utmost attention to the SNCF employees affected by these changes. The operational program includes an essential section on training and skills upgrading for all staff, so that they can all be helped to make the new train their own.

Industrial innovations and French manufacturing

To make a success of this major innovation project, Alstom has rethought its industrial manufacturing process in a standardization and lean manufacturing approach. Investments of nearly 50 million euros have been made in new production lines ensuring the safety of operators and the ergonomics of workstations, as well as industrial efficiency and the simplification of assemblies to make the solution competitive.

Ten of the sixteen Alstom sites in France are involved in the design of the new train: Belfort for the locomotives, La Rochelle for the carriages (studies, industrialization, purchasing, manufacturing and testing of passenger carriages), logistical and service support, and project management; Villeurbanne for the computerized control and command system, passenger information and on-board equipment; Ornans for the engines; Le Creusot for the bogies; Tarbes for traction; Toulouse (COE electrical) for the electrical circuits; Petit Quevilly for the transformers; Saint-Ouen for design, signalling, and Valenciennes for the study of the interior design elements.

In total, 4,000 jobs will be generated by this project in the French rail industry.

A train designed for customers and agents

All the new features of the TGV M have been designed with and for future users, whether passengers or SNCF Voyageurs agents.

Customers

Customers will find innovations on board that will improve their comfort and service. In the passenger lounges, the interior design has been designed to promote rest and a muted atmosphere, for a serene and peaceful journey. Elsewhere, social areas have been designed for those who wish to enjoy themselves with friends or family. The windows have been enlarged for a panoramic view of the landscape. The lighting will adapt to the intensity of the natural light in the train. All seats, designed for optimal comfort, will have connectivity features, offering everyone a powerful WIFI. The bar of this new TGV has been completely redesigned to offer a new experience.

TGV M is the first TGV which, from the outset of its design, has been designed in close collaboration with associations for people with reduced mobility (notably wheelchair users and the visually impaired). It will be the first TGV to offer fully independent access to the train. A pivoting lifting platform will allow wheelchair users to access the train independently, right up to the room reserved for them, and a sound system to locate the doors will guide visually impaired people when they board.

Agents

- Drivers

For the first time, drivers were involved in the design of the driver’s cab. Using virtual reality goggles, a hundred drivers were given a virtual tour of the cab, with a choice of 3 space designs. The comfort, space and ergonomics of the driver’s cab have received a lot of attention. Indirect lighting has been introduced and controls have been positioned to facilitate work gestures.

- Maintainers

The stakes are high: the TGV M aims to reduce maintenance costs by around 30%. The TGV M was designed with the early involvement of TGV maintainers, to take advantage of their day-to-day expertise in the high-speed maintenance Technicenters. The TGV M is designed to facilitate maintenance and cleaning, thanks to simpler and more robust systems and components. And thanks to the layout of the components in the locomotives, on either side of a wide central corridor, facilitating interventions.

- Crew

The TGV M improves the ergonomics and working environment of the train crew. The design work for the spaces intended for them was carried out in conjunction with the engineers. A first space will allow them to store their personal belongings. And the second space will be reserved for welcoming customers. The objective is to offer more freedom to attendant in the management of the trip and services to customers.

Next steps for the TGV M

- The next major step will be the dynamic test phase at 200 km/h in Velim (Czech Republic) by the end of 2022. This opens the first chapter in a long period of testing for this high-speed train.

- The comfort of the seats will be tested by a representative sample of people to gather their feelings and adjust if necessary.

- The car dedicated to people in wheelchairs has several innovations. Work is continuing with the associations to finalize the technical adjustments and the choice of signage. Attendants and maintenance teams are also involved in this process, to identify changes in the way they work.

- The bar car has been completely redesigned. For this reason, the constructors are starting specific work to adapt the catering offer to this new space.