Exceptional Engines for Exceptional Projects

Eneria, the energy solutions division within Bergerat Monnoyeur SRL, is a recognized supplier of diesel and gas generator sets in Romania, with an extensive portfolio of functional and efficient projects, for more than 2 decades.

Here we briefly present that activity of Eneria that includes the supply and integration of diesel/gas Cat engines in a wide range of applications.

- Industrial applications, in which the engine drives special equipment: special cranes, compressors, draglines, crushers, irrigation motor pumps and/or other industrial pumping applications, mining, forestry machinery etc.

- DGB «Dual Gas Blending» engines, which can operate both with liquid fuel and with gaseous fuel, with high performance in reducing fuel consumption and emissions resulting from its combustion

- Engines with superior reliability and durability for railway and road transport applications that comply with European emission standards EU 1628/2016

- High-efficiency engines with low operating costs for agricultural machinery (harvesters, tractors etc.)

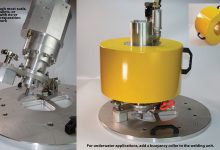

- Safe and efficient engines for oil applications: workover services, fire pumps, gas compressor stations, onshore and offshore drilling rigs, Hydraulic fracturing and oil and gas well drilling facilities, cementing units, as well as other special equipment used in drilling and intervention in oil and gas wells

- Propulsion engines and auxiliaries for marine applications

- Gas engines used both in the compression and in pipeline transmission of gas extracted from oil and gas wells

It is known that the technology of Cat® engines lives up to the toughest requirements and conditions of operation in the industrial field, complying with the highest quality standards, being in line with the latest requirements of reduction of pollutant emissions imposed in the European Union. Moreover, Eneria specialists are experienced in choosing and integrating engines in a large range of applications. Eneria engineers and technicians support the manufacturers of equipment since the design phase, providing technical assistance for choosing customized motorization solutions, providing specialized advice in completing the equipment. From the provision of Caterpillar equipment to its integration in client’s equipment according to the requirements and until the commissioning and testing or final approval of machinery, Eneria specialists come with all the technical expertise for implementing a successful project. The client therefore benefits from the most appropriate characteristics for complex projects. After delivery, throughout the warranty period and the period of operation of the provided equipment, Eneria provides equipment warranty, servicing, and maintenance services, so that the beneficiary obtains a maximization of operating parameters and a long life of Caterpillar engines and the equipment in which they were integrated.

No project is too small or too large for the world-class product line of Caterpillar industrial diesel engines. With powers range between 8.2 and 6100 kW (11 to 8180 hp), Cat® engines are strong enough to withstand the harshest working environments in the world, while being flexible enough to be configured on almost any machinery.The Caterpillar range of engines can be delivered in various arrangements fully equipped with all the systems necessary for operation, ensuring for manufacturers of special machinery a minimum degree of integration. These engines called Caterpillar IOPU – Industrial Open Power Unit, once purchased by the client are easy to integrate on the equipment, they being a Plug & Play solution. Exhaust gas treatment systems mounted in the factory on the engine, tested and approved by Caterpillar, ensure an easier final approval of the final equipment in which they were integrated. Optionally, they can be delivered with various engine-driven power outlets, which ensure flexibility and a decrease in the complexity of integration works.For the installation and integration of engines on various equipment, Eneria specialists provide the customer with execution drawings in 2D/3D formats, guides with mechanical and electrical installation recommendations, performance calculations of power groups, as well as technical assistance throughout the design of the final equipment.

Here are some recent images from behind the scenes of the process of motorizing some equipment.

Modernization by Remarul Cluj of narrow-gauge locomotive for the Heidelberg cement factory in Fieni. The locomotive transports stone conglomerates from the quarry, loading the train: 550 tons (wagons + stone).

Cat® C15 engine STAGE IIB 540CP@2100rpm pollution standards + Caterpillar TR43 transmission and Cat® TC45 torque converter mounted on engine. Other equipment and services provided by Eneria: hydraulic motor + transmission + converter circuit, converter motor coupling, crosshead between converter and transmission, extended warranty 24 months or 10,000 hours of operation, technical assistance for installation, commissioning, and final approval test for the locomotive.

VMS Vehicle Multi-Service – Hiarom. Special intervention equipment on roads and/or railways with two control cabins. Final destination: client from France, for use in subway intervention, for transporting various materials and equipment needed for tunnel repairs.

Cat® C7.1 engine STAGE V pollution standard power 205kW (275HP) @2200rpm, IOPU-Industrial Open Power Unit arrangement, 48-liter urea tank, engine-mounted hydraulic pump power take-off, technical assistance, mounting and commissioning.

The engine drives a hydraulic pump that provides all the controls of the equipment – the transport of the installation by road or rail. The platform on which the engine is mounted is also equipped with a hydraulically operated crane by the pump driven by the Cat® engine.

Dragline Promex – Braila; end-client Apele Romane.

Cat® C4.4 engine with STAGE IV pollution standard power 129.4 kW @2200 (173.5 hp).

Engine delivered in IOPU-Industrial Open Power Unit arrangement, 38-liter urea tank, accumulator batteries, Cat® control panel, technical assistance at installation, product approval audit, commissioning, and maintenance plan during the warranty period.

The engine drives a hydraulic pump, which drives the various systems on the dragline: tracks, storage winch, lifting cable, excavation coupling, dragline arm control etc.

Caterpillar engines are optimally and productively operated, ensuring performance and longevity for the projects they power up.

The key element at the heart of every exceptional product is an exceptional engine that runs day by day, month by month, year by year. This reliability is the result of a thorough and rigorous design and validation process.