World’s First Hydrogen-based, 1.5 MW Propulsion System for Aeronautical Applications

The world’s first hydrogen-based, 1.5-megawatt propulsion system for aeronautical applications will be realized in the BALIS project as a laboratory demonstrator and test environment for relevant hardware, system integration and control concepts. There is particular focus on the option of flexible integration of the main propulsion system components and validation in the test environment. The ability to map application-oriented load profiles provides ideal prerequisites for testing existing and newly developed hardware and allows the identification of technological gaps in the megawatt scale. The extensive test infrastructure also allows the development of propulsion system control technology.

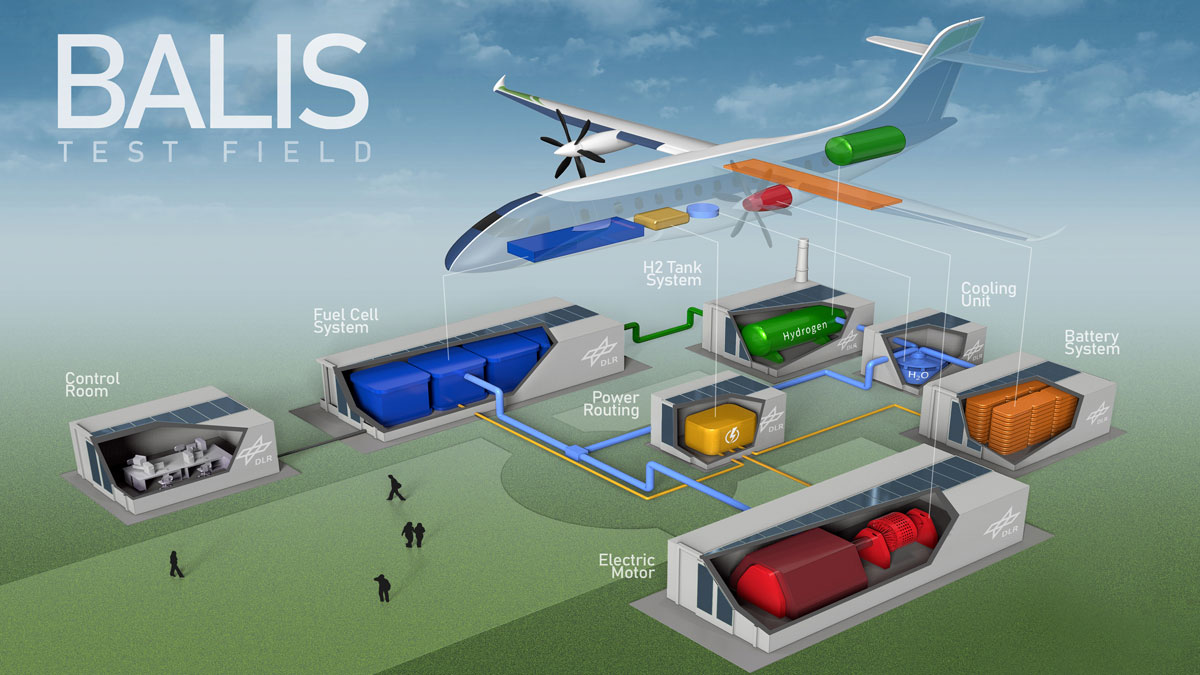

AVL is supporting the German Aerospace Center’s (DLR) BALIS project with a fuel cell composite testbed for up to 1.5 megawatts (MW) of power. The test field forms a development environment for hybrid, hydrogen, and electric drive concepts for passenger aircraft with a capacity of up to 60 persons. It comprises the necessary test infrastructure, as well as the main components of the propulsion system itself. These include fuel cell systems, the hydrogen tank, electric motors, a battery system, and the cooling system, as well as control and feedback control systems. The great variability and functional variety of the test environment allows research and development in line with diverse framework conditions, specifications, and guidelines. The project is funded by the Federal Ministry for Digital and Transport (BMVI).

At the Empfingen Innovation Campus in the Northern Black Forest, the DLR is setting up a 2,000 m² test field, the first of its kind in the world, to develop and test fuel cell propulsion systems for aircraft. AVL is supporting the project as a system partner with its container design solutions, which allow a flexible integration of various technologies (fuel cell systems, H2 tank, e-motors, battery system, cooling system, etc.) in the test environment. Furthermore, the container solutions require an impressively small amount of space, which suits the prevailing spatial conditions. The test field is scheduled to commence operation in autumn 2022.

“The BALIS test field is a unique infrastructure, in order to develop fuel cell systems for aviation. This will make it possible to achieve zero-emission flying,” says Professor André Thess, Director of the DLR Institute of Technical Thermodynamics.

“Hydrogen can be used as a fuel in many modes of transport. In the quest for environmentally friendly and sustainable mobility, AVL has assembled a wealth of knowledge and experience – through the challenges faced in developing and testing fuel cell systems for automotive applications. As a partner, we can now incorporate this in the extraordinary project, in order to accelerate the introduction of fuel cells in future aircraft. We at AVL are immensely proud of the involvement in this milestone in the research of zero-emission mobility,” explains Roland Jeutter, Managing Director of AVL Deutschland GmbH.

Depending on the application case, an elaborate switch matrix ensures a smooth power connection between the components. Accordingly, relevant load cases, including start and landing procedures, can be simulated, and investigated for aircraft. The control intelligence takes on a programmable logic controller, which forms a communication connection with the automation system, which is provided by AVL and adapted to the demands of the project.

AVL’s extensive core areas of expertise provide the best opportunities to master the complexity of integrating the propulsion system for aeronautical applications.

About AVL

With more than 11,000 employees, AVL is the world’s largest independent company for development, simulation and testing in the automotive industry, and in other sectors. Drawing on its pioneering spirit, the company provides concepts, solutions, and methodologies to shape future mobility trends. AVL creates innovative and affordable technologies to effectively reduce CO2 by applying a multi-energy carrier strategy for all applications – from hybrid to battery electric and fuel cell technologies. The company supports customers throughout the entire development process from the ideation phase to serial production. To accelerate the vision of smart and connected mobility AVL has established competencies in the fields of ADAS, autonomous driving and digitalization.

AVL’s passion is innovation. Together with an international network of experts that extends over 26 countries and with 45 Tech- and Engineering Centers worldwide, AVL drives sustainable mobility trends for a greener future. In 2020, the company generated a turnover of 1.7 billion Euros, of which 12% are invested in R&D activities.

The BALIS project

As part of the National Innovation Programme Hydrogen and Fuel Cell Technology (NIP), the BALIS project receives € 26 million of funding from the Federal Ministry for Digital and Transport (BMVI) and is financed through the Energy and Climate Fund. The funding guideline is coordinated by the National Organization Hydrogen and Fuel Cell Technology (NOW) and implemented by Project Management Jülich (PtJ).