Powering the World with Magnets

One of the most amazing phenomena of nature is the manifestation of magnetism in some materials. Permanent magnets are known since ancient times. Before the great discoveries in the field of electricity, permanent magnets were actively used by physicians. Over time, people learned to create artificial magnets by placing iron alloy products in magnetic fields. Permanent magnets are frequently used in industry, in various fields, such as electrical engineering, computer technologies, transportation, navigation, medicine, biology, astronomy etc. The main application of magnets is in electrical engineering, radio engineering, instrumentation, automation and tele-mechanics. For example, without magnetic materials, electrification would be impossible because generators, transformers for power transmission, and speakers for electric motors, telephones, radios, and televisions would be used for power generation.

The active introduction of permanent magnets in the sphere of human activity stimulates inventing and creating new ferromagnetic alloys with improved magnetic characteristics.

Pure magnetic metals

Iron, cobalt, nickel, gadolinium – only these four metals are pure and magnetic at ambient temperature. This property is called ferromagnetism. All rare earths alloys used industrially for permanent magnets contain these metals.

However, there are 9 metals that have strong magnetic properties, being able to be attracted by magnets and they themselves are able to become magnets: iron, cobalt, nickel, but also gadolinium, terbium, dysprosium, holmium, erbium, thulium. Aluminium, platinum, chromium, titanium, vanadium, manganese are very weakly attracted by magnet. They magnetize so little that it is impossible to detect their magnetic properties without special tools.

Ferromagnetic metals

Ferromagnetic metals are strongly attracted by objects with magnetic fields and can keep their magnetic properties after the magnet is removed from them. They are used to create permanent magnets. The main ferromagnetic metals are iron, nickel, cobalt, gadolinium, and dysprosium. If a piece of ferromagnetic metal is held next to a magnet, a strong enough attraction will be felt.

Ferromagnetic alloys

Ferromagnetic alloys are materials such as steel, which contain ferromagnetic metals. Steels is a combination of iron and several other metals and is harder than iron. Due to this hardness, steel can retain its magnetism longer than iron. When heated at high temperature, steel loses its magnetic properties. This will also happen to ferromagnetic metals such as nickel.

Ferrimagnetic materials

Ferrimagnetic materials are ferrite, magnetite, and magnesium. They all have as main component iron oxides, as well as oxides of other metals. Lodestone is magnetite that is naturally magnetized. Magnetite is attracted to magnetic fields, but usually does not magnetize itself. Ferrimagnetic materials are similar to ferromagnets, but with a smaller magnetic attraction.

Paramagnetic metals

Paramagnetic metals are weakly attracted to magnet and do not retain their magnetic properties when removed from the magnet. These include copper, aluminium, and platinum. The magnetic properties of paramagnetic metals depend on temperature and aluminium, uranium and platinum become more attractive for the magnetic fields when they are very cold. Paramagnetic substances have much lower attractive forces for magnets than ferromagnetic materials and very sensitive instruments are needed to measure magnetic attraction.

Is stainless steel magnetic?

There are over 120 different types of stainless steel! If an alloy contains at least 12% chromium, it can be considered rust-resistant stainless steel. Most stainless steels are made of austenitic alloys and are only slightly magnetic. Steel with ferritic or martensitic structure is magnetic. If a type of steel contains a mixed structure of ferrite and austenite, the proportion of ferrite determines those magnetic properties of the steel.

There is a widely spread myth about the magnetic behaviour of stainless steel. Many people think that all types of stainless steel can attract a magnet. That’s not true at all. In fact, magnets work on some types of stainless steel. There are many types of stainless steel, but we can classify them in two major categories: austenitic and ferritic. Each classification has unique atomic arrangements. For this reason, we often meet some stainless steels that are non-magnetic and others that are. The basic stainless steels with a ferritic structure will attract a magnet, unlike the more common austenitic types. Due to the structure and high iron concentrations, ferritic stainless steels are magnetic.

Stainless steel is an alloy of iron, carbon, and chromium. It has good corrosion resistance and is very strong. However, it has no magnetism. So, how is it used to make magnets?

The answer is found in the laws of physics. In the molecular structure of metals, there are several atoms that generate micro magnetic fields. In a free, disordered assembly of atoms, the different magnetic fields do not form a common force but cancel each other out. In this case, there is no magnetic field. On the other hand, if atoms are assembled in the same direction, their magnetic fields do not cancel each other out, but coordinate themselves and, therefore, gather, generating a strong magnetic field. This is why some metals such as iron will be attracted from another magnetized metal, as their micro magnetic fields align in the same direction and form the magnetic field of the magnetized metal.

Recognizing stainless steel

If it smells, then it is not stainless steel. It can be polished or painted but will also contain other elements. Some manufacturers add a small amount of nickel (or another metal) in their stainless steel to attract magnets. It is not truly stainless steel, but rather a combination of stainless steel and nickel alloy. For a piece of stainless steel without rust, it is necessary to have a grade of ‘304’ or ‘316’.

Types of stainless steel

- Ferritic stainless steel is a steel to which chromium has been added.

- Martensitic stainless steel is composed of iron and chromium, with a high carbon content.

- Austenitic stainless steel, low in carbon but with nickel.

The other types of stainless steel, ferritic and martensitic, develop a weak magnetization. Specifically, the solidity of stainless steel, its stainless nature, shock resistance has nothing to do with the fact that it is magnetized. As for their use, it should be mentioned that welding on ferritic stainless steel will irreparably affect the molecular structure, which can cause problems. On the other hand, austenitic stainless steel welds perfectly. A ferritic stainless steel does not rust, corrosion resistance is a matter of chemical composition and has nothing to do with its magnetic capacity.

Magnetic steel, the less known part of the electric motor

Magnetic steel, doped with silicon and rolled into thin sheets, is essential for making the heart of electric motors. Despite increasing the production capacity of steel producers in Europe, demand could exceed supply. In the shadow of concerns related to nickel and cobalt, magnetic steel is a much more discrete alloy that could slow down the rise of electric vehicles and which pushes manufacturers to urgently adapt their capacities. This year, in mid-March, the steel giant ArcelorMittal announced that it would invest over EUR 300 million in its site in Mardyck to install electric (or magnetic) rolling mills. While this allow is not known by the general public, the announcement was expected from the sector. In the rotors and stators of electric motors and in transformers, this steel doped with silicon and stacked in thin slices is essential for optimizing the circulation of the magnetic field and guaranteeing a good performance of the car.

Magnetism of gold

Pure gold is not attracted by magnets. The impure gold pieces become slightly magnetic under a large magnetic field. Gold is diamagnetic and paramagnetic, and the effects can cancel each other out. Therefore, gold is neither attracted nor repelled by a magnet. An impure form of gold, such as 18- and 22-carat gold jewellery, consists of ferromagnetic materials. These materials are added to make gold harder and more resistant to wear.

In such cases, the magnetism of gold depends on the metal fused into it. For example, if producers mix gold with iron, it will produce an extremely magnetic alloy. If mixed with silver, it will result in non-magnetic white gold.

Magnets can be useful to test gold coins and bars. If the gold coin is over 99% pure, then it should not be affected by a magnet.

Gold can be magnetized by applying heat

In 2016, a team of researchers at Tohoku University, Japan, discovered that gold could be magnetized under the heat generated by a temperature gradient. The study also highlights the electron transport property altered by spin injection and thus provides a versatile approach for the generation and detection of non-equilibrium magnetization in ordinary metals.

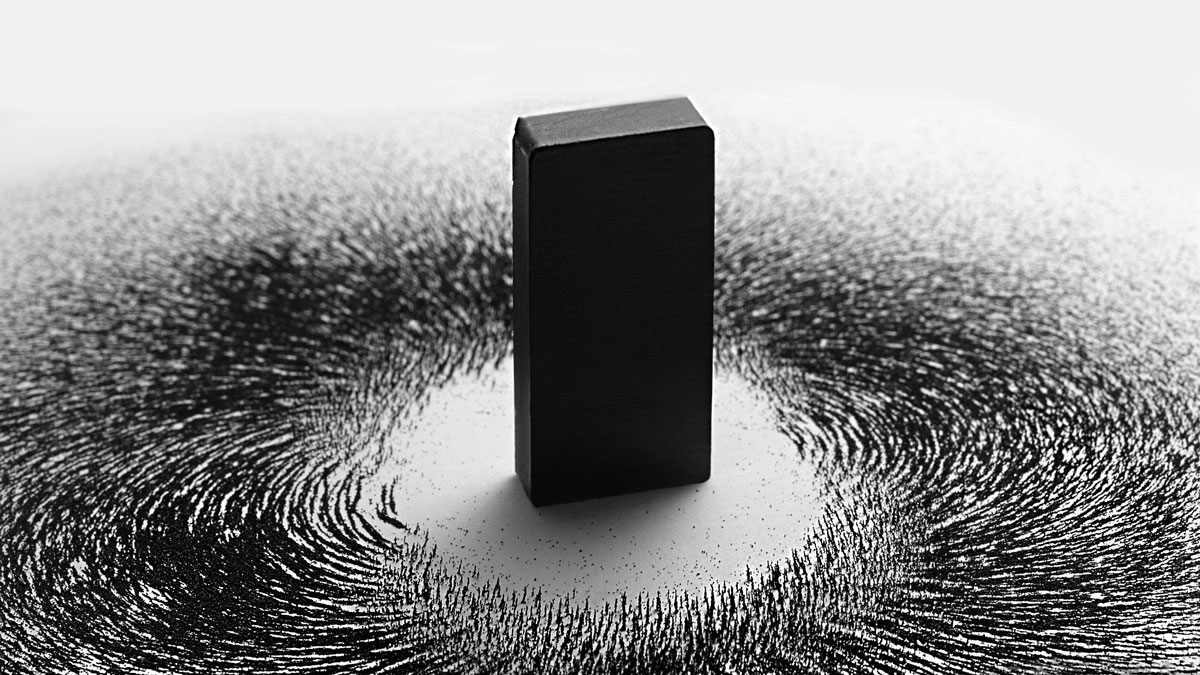

Permanent magnets

Permanent magnets are ‘hard’ magnetic materials, i.e., materials that, once magnetized, retain their magnetization at the temperature of use. Their magnetic properties are primarily determined by the properties of the compounds that constitute them. Also, they depend a lot on the microstructure of the material obtained through the manufacturing process.

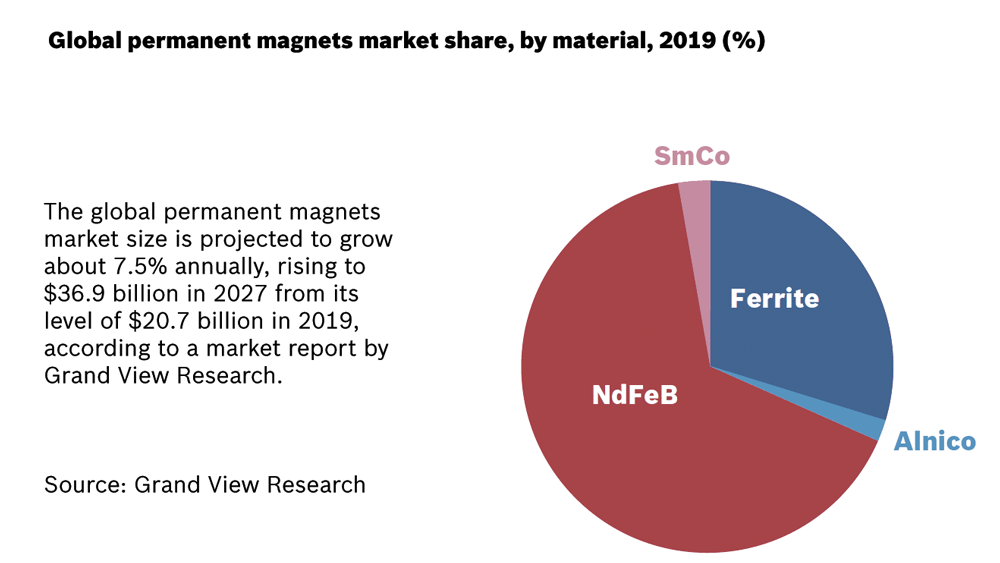

Four families of materials for permanent magnets are used in most applications in the market. These are alnicos, hard ferrites, samarium-cobalt, and neodymium-iron-boron. There are also other materials, but their applications are very limited. These are: ductile alloys, manganese-aluminium-carbon alloys, hard martensitic steels, or micro powder-based magnets.

The term permanent magnet comes from the magnet’s ability to retain an induced magnetic charge after it is removed from the magnetizer. Permanent magnets are needed to make compasses, radio transmitters, various electrical measuring instruments etc. Usually, they are made of steel with high carbon content. Permanent magnets are starting to be used in a new highly magnetizable alloy called magnico, which consists of cobalt, nickel, copper, aluminium, and iron.

Best metals to use in a magnetic circuit

Solid steel is generally the best choice, from an economic point of view, in static field devices. Low carbon steel (ASME 1006 – 1018) should be used for pole parts, if possible, and should be enriched with hydrogen after processing. The 400 series stainless steels can be used, but they are not as good magnetically as low carbon steel, so parts may have to be larger to compensate.

Difference between AlNiCo, SmCo, and NdFeB magnetic materials

AlNiCo is an older magnetic material that still has important applications. Its maximum energy product is about 1/5 of SmCo materials, but it has excellent properties at high temperatures and better corrosion resistance. AlNiCo can be cast in different shapes with different magnetic orientations. AlNiCo magnets have been widely used, initially in military electronic applications and later in civilian versions such as automotive and aircraft sensor applications. The development of Alnico magnets marked the beginning of a new way of thinking about magnetic materials where composite materials with multiple phases produced attribute superior to those of the individual components.

The drive towards neodymium-iron-boron (NdFeB) magnets was a result of the increased cost of Co in the late 1970s, a critical ingredient in the SmCo magnets.

SmCo and NdFeB rare earth magnets have high coercivity, so they do not need to be magnetized in the circuit and can be used with low permeability coefficients (i.e., thin disks). These materials are also suitable for testing the Helmholtz coil due to their normal straight-line curves. This also makes rare earths ideal for engines and high field dipoles. SmCo has good resistance to thermal demagnetization but is fragile. NdFeB is less brittle, has poor thermal properties and is prone to corrosion.

Advantage of a permanent magnet compared to an electromagnet

In general, the space volume necessary to produce a certain static field will be lower for permanent magnets when the working space is small; electromagnets win in larger devices. The limiting factors for electromagnets are the space consumed by the windings, the power supply and the heat generated during operation. Permanent magnets do not require a power supply, so they save space and energy. An adjustable power supply makes it easy to adjust the magnetic field of an electromagnet by simply adjusting the input current. However, adjustable permanent magnets can be used if the field does not need to be adjusted frequently.

Why are rare earths magnets so expensive?

In the case of rare earths magnets, the metals used to improve the magnetic properties are difficult to extract. The magnet-related elements are a small fraction of the lanthanides mined, so material cannot be produced in huge quantities. Since the fine powders are pyrophoric, production conditions need to be very tightly controlled, and there is a limit to the size of block that can be formed due to the pressure required. Subsequent processing of the magnets increases the costs. As the magnets are typically very hard, grinding and processing operations are slow.

Role of magnets in green energy

Magnetic materials especially permanent magnets are critical for the efficient performance of many renewable energy technologies. The increased reliance on renewable energy sources has accelerated research in energy-related technologies the world over. The use of rare earth metals in permanent magnets continues to be a source of greater concern owing to the limited rare earths supply coupled with dwindling reserves on the globe.

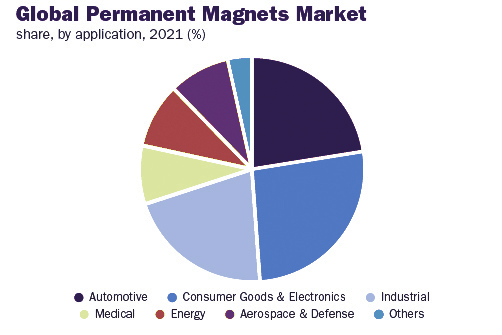

The drive behind the development of permanent magnets emanates from the need to obtain high magnetic energy product over smaller volumes of magnets, which could be utilised in a few technological applications such as clean energy technologies (wind turbine generators and hybrid regenerative motors), transportation components, and consumer products. Magnetic materials play a pivotal role in modern society owing to their unique ability to perform several tasks as follows: convert mechanical to electrical energy; transmit and distribute electric power; facilitate microwave communications; provide basis for data storage systems (Wallace Matizamhuka – The Impact of Magnetic Materials in Renewable Energy).

NdFeB permanent magnets enable the replacement of mechanical gearboxes in wind turbines with direct-drive permanent magnet generators thus reducing the overall turbine weight, cost of other components such as concrete and steel required to support heavy gearboxes, and a reduction in the number of moving parts which basically allows for greater reliabilities and efficiencies. Permanent magnet synchronous generators use the magnetic field of strong rare earth magnets to convert the energy from the spinning blades into electricity. These generators can operate at low speeds, which allows them to be powered by the turbine shaft directly, eliminating the need for a gearbox. This reduces the weight of the wind-turbine nacelle. The elimination of the gearbox results in improved reliability lowered maintenance costs and improved efficiency. The properties of magnets that allow designers to eliminate mechanical gearboxes from wind turbines illustrate how magnets can be used innovatively in solving both operational and economic problems in modern wind turbines.

Today, electric/hybrid electric vehicles have re-emerged as a realistic alternative to gasoline internal combustion vehicles. The success of EVs is owed to the highly efficient permanent magnet motors used to run the power train of the EV. The use of hard magnetic material NdFeB offers quite significant benefits, which has enabled the development of highly efficient traction motors not possible with other technologies.

Instead of wind rotating turbines, hydropower uses flowing water. Hydropower technologies generate power by using the elevation difference, created by a dam or diversion structure, of water flowing in on one side and out, far below, on the other. Water flows through the dam and turns a large wheel called a turbine. The turbine turns a shaft which rotates a series of magnets past copper coils and a generator to produce clean, renewable electricity.

Solar power uses solar panels to convert energy from the sun into thermal or electrical energy. In the manufacture of these solar panels, thin films are deposited in multiple layers through a process called ‘sputtering’ or PVD (physical vapor deposition). To optimize this process, permanent magnet assemblies improve the utilization of the material being deposited.

Magnets are used to create electrical currents in the geothermal process. As the hot fluid expands and creates the mechanical energy needed to turn the turbine blades, the turbine spins magnets inside a large coil, creating an electrical current.

The use of soft magnetic materials in transformers for power generation and conversion for the electrical grid plays a pivotal role in electricity generation. The performance of soft magnets is material specific and is dominated by properties such as low coercivity and core losses, high saturation magnetisation, resistivity, and permeability, which makes these materials more attractive for the efficient transmission and distribution of electricity.

Magnets for the oil & gas sector

The oil and gas industry presents some of the most challenging environments and demanding applications for magnets and magnetic assemblies. For this industry it is recommended to use rare earth magnets, such as neodymium and samarium cobalt magnets. This is due to their highly desirable properties such as their high coercive force and high-temperature stability. While samarium cobalt magnets have corrosion resistant properties, neodymium magnets do not. Moreover, rare earth magnets are used to remove scales that are created by aging oil equipment, pipes, and unwanted ferrous materials.

In conclusion, the properties of magnets are widely used in various fields, being useful for all mankind.